The global energy landscape is undergoing a profound transformation as the world embraces fuels from renewable sources. Generators typically fueled by natural gas – like those found in combined cycle power plants (CCPPs) – will have to adapt fast.

Recent analysis from GlobalData suggests that fossil fuels continue to dominate active power plant capacity among the world’s top plant owners. 5,327 new power plant projects have been announced as of July 2024 according to GlobalData’s power plant database, and, while many will be constructed with renewable energy in mind, it is clear that others will be forced to rapidly roll out bridging technologies over the coming years.

CCPPs have long been valued for their efficiency and reliability. Utilizing both gas and steam turbines to generate electricity, they can achieve higher efficiency levels than simple-cycle power plants. However, the rise of wind, solar and other renewable energy sources is transforming their operational roles. The rotating mass of turbines in CCPPs provides essential inertia and offers grid stability in the face of sudden power output changes. CCPPs can adjust their output to balance fluctuations caused by variable renewable energy generation, offering vital frequency response capabilities.

It raises the challenge of transitioning from power generating mainstays to nimble providers of backup energy – a considerable one for CCPP operators. Traditional maintenance and operational strategies will need to change. “An holistic view on the whole combined power plant and its processes is key to staying competitive,” argues Matthias Nickl of Siemens Energy. “The application of robots and drones as well as remote operation along with Artificial Intelligence and the know-how and support of the OEM will be crucial to maintain reliability during operation and maintenance.”

Embracing flexibility, leveraging advanced technologies, and aligning with regional energy policies are crucial strategies for ensuring the continued relevance of CCPPs. As Nickl says, their operators “face massive challenges, but also great opportunities to become leaders within the energy transition.”

CCPPs in the renewable energy era

Because CCPPs weren’t necessarily designed with flexible operational schedules in mind, operators face a quandary. The commercial foundations on which their plants were planned are changing.

For example, Germany’s Hamm-Uentrop plant operates two Siemens Energy single shaft configurations. Originally designed for 8,000 annual hours, changing market conditions have represented a challenge; with slim margins, part-load operations and volatile prices, owner Trianel has been keen on efficiency and emissions improvements.

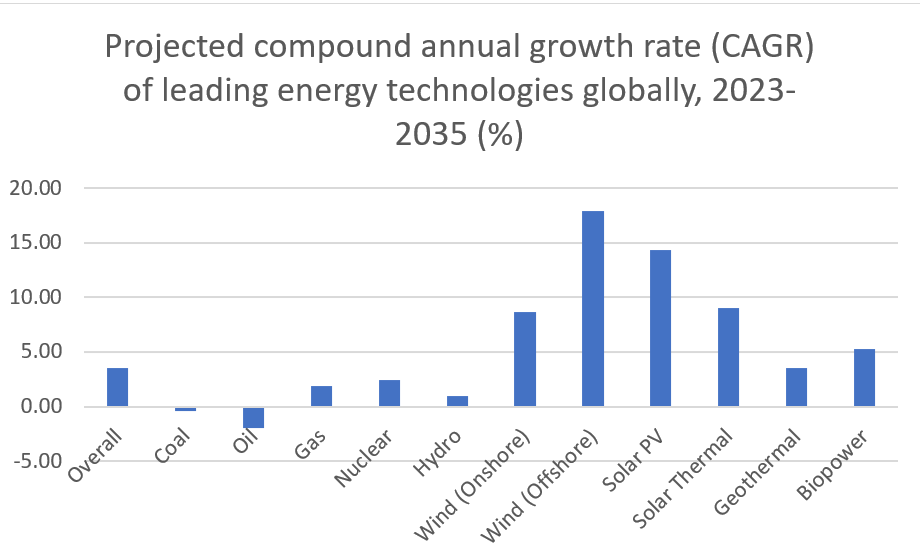

Conditions are similarly challenging for CCPPs across the Atlantic. North America’s energy transition is accelerating, driven by technological advancements and favorable policies boosting renewables, hydrogen, and CCUS innovation, according to GlobalData research. Natural gas currently dominates at 40% of capacity; however, renewables are set to surge from 36% in 2023 to 52% by 2030 and 62% by 2035. Solar PV and onshore wind will dominate, growing at 14.6% and 5.4% CAGR respectively in the same period. Meanwhile, coal’s capacity will decline sharply, with a negative CAGR of 3.8%.

To remain profitable, CCPP operators must manage their plants’ output efficiently, minimizing losses during low-priced hours and maximizing revenue during peak periods. One effective strategy is to lower the plants’ minimum operational capacities during non-profitable hours, thereby reducing costs and losses. Specific solutions to increase flexibility include improving start and stop performance, reducing outage times, enhancing demand response capabilities, and automating energy management. These measures can enable CCPPs to quickly adjust their output, capture market opportunities, and maintain competitive positions.

“With a highly flexible power plant solution you may be able to help your long-term profitable market positioning,” says Nickl. “For instance, you may be able to enhance your competitive position, improve your energy dispatch ranking, and meet as often as possible the sweet spot at times of high energy prices.” Flexibility solutions have become a must-have for CCPP owners. The question is not if they should implement them, but when – and what kind of partnerships can help them to do so most effectively.

The Siemens Energy solution

In the quest to remain competitive, what do new operational strategies and technologies look like in practice for CCPPs? Returning to Hamm-Uentrop, the plant is leveraging its ability to provide ancillary services such as secondary frequency response and minute reserve as a strength amid the ongoing energy transition. Crucially, by implementing Siemens Energy’s Advanced Operational Flexibility solutions over the past decade, the plant has ramped up its fast start and shutdown capabilities. Doing so has extended the plant’s operational lifespan – ensuring consistent revenue by making it a regional leader in supplying power when demand spikes.

In 2018, Trianel initiated a series of upgrades, starting with Hot Start on the Fly to reduce start-up times. By 2021, further enhancements halved warm-start and shutdown durations. The most recent hardware upgrades under the Advanced Turbine Efficiency Package (ATEP) will mean better performance and lower emissions. And all these improvements fall under a bespoke long-term service agreement with Siemens Energy, ensuring robust operational support and continuous innovation.

Creating strong partnerships with industry energy experts paves the way for CCPPs to adapt further in the future. As Germany transitions from nuclear and coal power, Trianel is exploring hydrogen integration, aiming to blend 10-20% hydrogen into its fuel mix. Siemens Energy will be pivotal in retrofitting the plant for hydrogen co-firing, positioning Trianel at the forefront of the energy transition.

Siemens Energy offers a comprehensive portfolio of technologies and systems designed to enhance the operational flexibility and efficiency of CCPPs. One such offering is the Flex-Power Services™ portfolio, which includes a range of products and solutions aimed at meeting the diverse needs of power plants in a dynamic energy market. These services can be provided as retrofits, often combined with other modernization efforts to maximize their impact.

One of the core features of Flex-Power Services™ is Start and Stop Optimization solutions, which focus on improving start and stop performance. These upgrades are designed to decrease the wait for water-steam cycle warm-up, eliminate holding times, and increase ramp rates for steam and gas turbines. Shortening start-up and shutdown times means these solutions help reduce fuel consumption and emissions, offering both financial and environmental benefits.

Demand response capabilities are another critical aspect of Siemens Energy offerings. These upgrades enhance grid services and peak power capabilities, enabling plants to follow load changes more effectively and provide essential frequency response services. Enhanced ramp rates and load-following capabilities ensure CCPPs can quickly adjust their output to meet grid demands, making them central to supporting overall grid stability.

In markets with high variability in energy supply, part load capabilities become crucial. Siemens Energy upgrades in this area focus on reducing minimum load requirements for gas turbines and plants, improving part load efficiency and addressing part load emissions. These enhancements ensure that CCPPs can operate efficiently even during periods of low demand, maximizing their uptime and profitability.

Finally, downtime flexibility. Advanced preservation concepts and rapid cool-down solutions allow plants to maintain a state of readiness for fast restarts, even after extended shutdowns (e.g. for up to two weeks). It is a capability that ensures plants can power up quickly when needed.

As the global energy landscape continues to evolve, the ability of CCPPs to adapt and remain flexible is more important than ever. Siemens Energy advanced technologies and domain know-how provide CCPPs with the tools they need to navigate this transition effectively. Working with an industry expert like Siemens Energy offers CCPPs a ready-made portfolio of technologies designed to help them maximise their flexibility. As the Hamm-Uentrop plant from Trianel shows, this can offer operators all the assurance they need as the energy transition gathers pace.

Nickl says more plants should start deploying these solutions sooner rather than later: “Get your flexibility improvements now! Implementation of the tailormade solution based on deep OEM know-how sets you in the front seat of the energy transition.”

Siemens Energy are on hand to roll out their flexibility solutions in your CCPP today. Download the whitepaper on this page to learn more.