Condition-Based Monitoring in Power Generation with Visplore

In the dynamic world of power generation, ensuring the reliability and efficiency of your assets is paramount. Traditional time-based maintenance schedules can be costly and inefficient, leading to unnecessary downtime or missed opportunities to prevent failures. This is where condition-based monitoring (CBM) emerges as a powerful tool, empowering you to predict and address equipment issues before they cause disruptions. Visplore, with its advanced data analysis and visualization capabilities, becomes your key to unlocking the full potential of CBM in your power plant.

The Power Plant Challenge:

- Data Overload: Managing and analyzing vast amounts of data from diverse sources like SCADA systems, sensor networks, and maintenance logs can be overwhelming.

- Hidden Anomalies: Subtle changes in sensor readings or equipment behavior often go unnoticed, leading to undetected issues and potential failures.

- Limited Insights: Traditional methods may struggle to identify the root cause of problems, hindering effective maintenance strategies.

- Reactive Maintenance: Relying solely on time-based maintenance can lead to unnecessary downtime and missed opportunities for preventive actions.

Visplore: Your CBM Partner for Enhanced Reliability:

Visplore offers a comprehensive suite of CBM features designed to overcome these challenges and empower you to:

- Unify Data from Diverse Sources: Seamlessly integrate data from various sources, including SCADA systems, historians, and sensor networks, creating a holistic view of your plant’s health.

- Detect Anomalies with Precision: Utilize advanced statistical analysis and intelligent algorithms to identify subtle deviations from normal operating conditions, pinpointing potential issues before they escalate.

- Drill Down to Root Causes: Employ correlation analysis and visualization tools to explore relationships between diverse parameters, uncovering the underlying causes of anomalies and guiding targeted maintenance actions.

- Implement Proactive Maintenance: Predict equipment failures based on historical data and real-time trends, enabling proactive maintenance and minimizing unplanned downtime.

Benefits Tailored for Power Generation:

- Reduced Downtime: Predict and address issues before they cause disruptions, minimizing unplanned downtime and ensuring smooth plant operation.

- Extended Equipment Lifespan: Implement timely maintenance based on actual equipment condition, extending asset life and reducing replacement costs.

- Optimized Maintenance Costs: Prioritize maintenance activities based on criticality, allocating resources efficiently and minimizing unnecessary maintenance expenses.

- Improved Plant Performance: Maintain optimal equipment performance by identifying and addressing potential issues before they impact efficiency.

- Enhanced Risk Management: Proactively mitigate potential failures and ensure the safety and reliability of your plant operations.

Real-World Example:

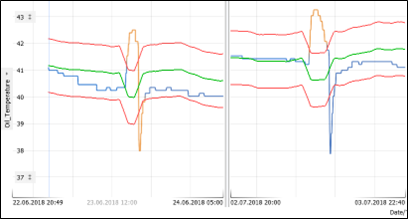

Imagine a power plant experiencing unexpected shutdowns due to overheating issues in critical turbines. Visplore can:

- Analyze historical data and sensor readings to identify subtle changes in operating parameters preceding the shutdowns.

- Correlate these changes with specific equipment components, pinpointing the root cause of the overheating.

- Predict future overheating events based on real-time data and historical trends, enabling proactive maintenance interventions.

Conclusion:

Visplore empowers you to move beyond reactive maintenance and embrace a proactive approach to CBM in your power plant. By leveraging its advanced data analysis and visualization capabilities, you can gain deeper insights into your equipment health, predict potential issues, and implement targeted maintenance strategies. This translates to improved reliability, reduced costs, and ultimately, a more efficient and sustainable power generation operation.