Industrial IoT company EkkoSense has teamed up with electricity network provider Scottish and Southern Electricity Networks (SSEN) to trial autonomous sensors capable of alerting companies of damage to their power poles. As SSEN explains, the project known as RAINMAN involves “data being collected by remote sensors, which will then be used to provide advance warning of potential infrastructure irregularities, helping us to respond more quickly when remedial action is needed.”

Industrial IoT company EkkoSense has teamed up with electricity network provider Scottish and Southern Electricity Networks (SSEN) to trial autonomous sensors capable of alerting companies of damage to their power poles. As SSEN explains, the project known as RAINMAN involves “data being collected by remote sensors, which will then be used to provide advance warning of potential infrastructure irregularities, helping us to respond more quickly when remedial action is needed.”

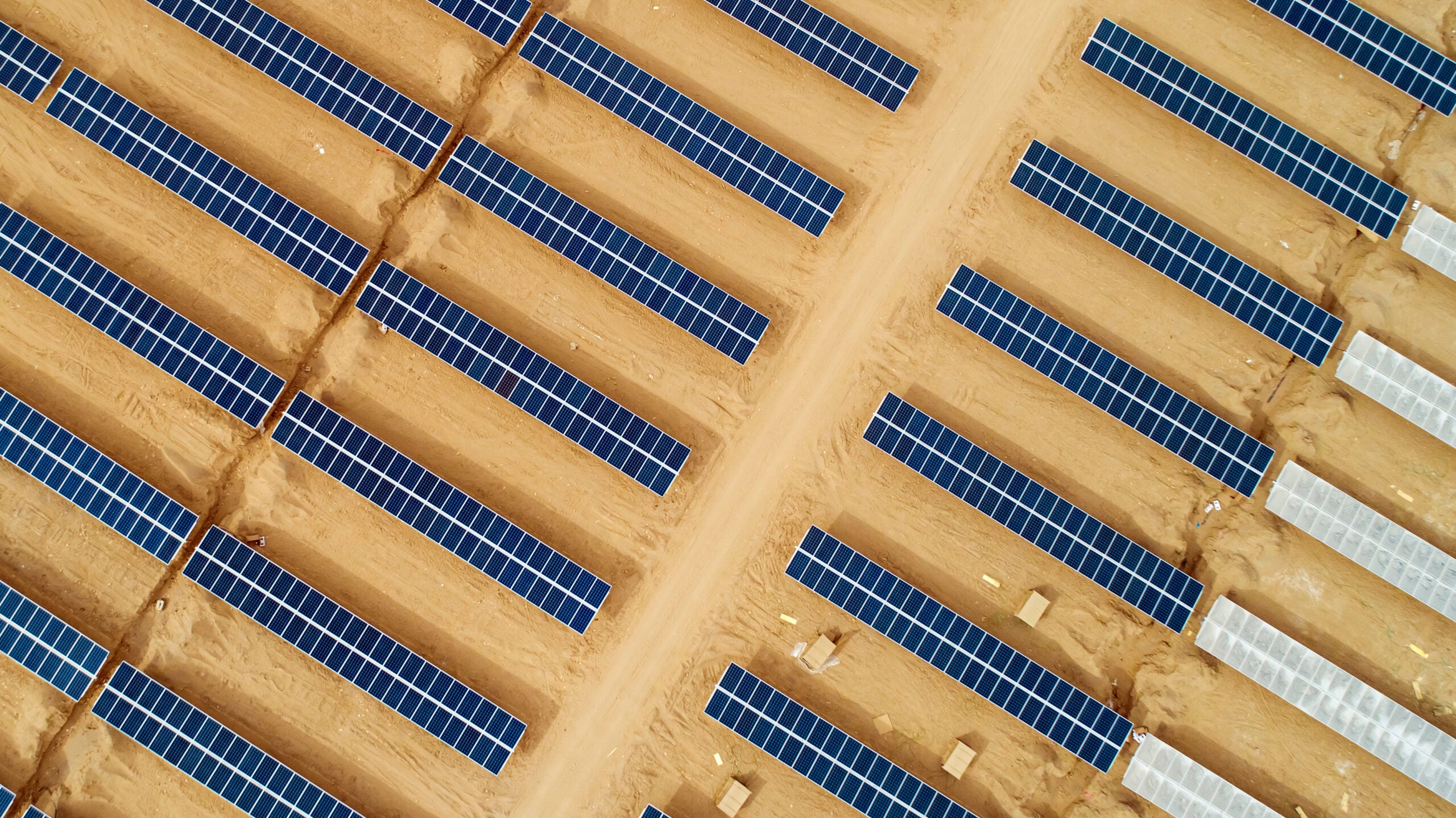

The solar powered sensors will be able to track even slight movements in the position of power poles, and then combine this with data from weather forecasts to accurately predict possible damage.

SSEN operates in some of the remotest and most hazardous areas of the UK, where severe weather is a constant threat to power. “One of the problems faced by power companies to improve integrity and resilience of the network,” says EkkoSense founder and CTO Stu Redshaw. “Among the many causes of power cuts, in remote and hard to reach places power transmission lines are often hit by very severe storms, struck by lightning or even pushed over by high winds.”

The sensors EkkoSense is developing with SSEN are designed to predict damage before it can occur, making the network as resilient as possible. The project partners are launching trials at one of SSEN’s test sites on the Isle of Skye this spring following successful laboratory tests. If these trials prove successful the technology will be further tested across the whole island in summer.

A threefold system

The technology has three components; the sensor itself, the communications system and the software. EkkoSense have years of experience with the sensors but Redshaw points out that this is a slightly unusual application for the company. “We normally are more concerned with heat monitoring, [but] the principles are actually exactly the same,” he says. “We're just looking at an industrial system that's very important to the operators of that system, and trying to provide the data that has been missing so that they can understand its performance.”

The sensors provide a constant stream of information, or a ‘heartbeat’ for the system, measuring the minutest movements of the power poles. “The heart of our technology is a state-of-the-art electronic gyroscope, like the type used in drones to report back extremely precise position and motion data,” says Redshaw. “This data is fed into a complex algorithm that tells us if any structures that support power lines are at risk of falling over and possibly even when that may occur.”

The sensors must be tough, weathering the conditions they are monitoring. “The sensor itself is autonomous, it’s self-powering using solar, and is designed to operate in the most extreme weather conditions and continue to operate even in the dark winter months,” says Redshaw.

The system’s heartbeat, once collected by these sensors, must travel 20km to an SSEN site in order to be analysed. The system used to analyse the information is key to its implementation, and relies on EkkoSense software. “We have a massive analytics engine that processes huge amounts of data, and we've been used to doing that for a number of years,” says Redshaw.

The combination of all three aspects creates a system which can sense minute changes and analyse them against weather data. “We can use some very advanced algorithms and analytics to try and see if in light winds if a pole moves a certain amount,” Redshaw explains. “Then we can start to predict future performance based on future weather forecasts.”

They have come a long way

Whilst this is not the first time that remote sensors have been tested for power poles, EkkoSense and SSEN claim their project is the first economical solution to the problem. “The individual components that make up our technology have each come down in cost, so that we can now integrate them together into an individual sensor that has a cost-point that makes it economic,” says Redshaw.

Given the remote locations and severe weather the technology is designed for, maintenance of the sensors could be considered a future challenge. But it is easy and cheap to replace a sensor if necessary, says Redshaw, adding: “It’s low enough cost, and so far away from any inhabited areas that it just has to be fitted. You fix it to the pole, and then you leave it alone and it just does its stuff.”

The biggest challenge the project faced was the communications element. ”What made this project particularly difficult for us has been developing a very low power communications system,” says Redshaw. “To give you an idea of how much power budget we had to play with for our communications, each individual sensor has to use less power than a key fob that works the locks on a car door to transmit signals over 20km.”

The breakthrough in the technology came last autumn, when EkkoSense managed to incorporate state-of-the-art Internet of Things communications systems and generate a low power wide area network (LPWAN) system, says Redshaw. This LPWAN system proved successful, transmitting over vast areas and running, as the whole sensor does, just off of the solar panels attached to the power poles.

EkkoSense and SSEN’s system has a lot going for it, combining new technology in the form of the communications system and well-tested software. The resulting systems could dramatically reduce the amount of damage severe weather conditions cause in the UK, all that’s left is to see how well it performs in the trials.