Vichem is an environmental engineering company which designs, installs and commissions units for the treatment of industrial waste. Vichem has been doing business for over 60 years, worldwide and with an international team.

For the power industry, our technologies apply to:

- Treating hazardous waste from oil and gas companies and refineries

- Dismantling old transformers with destruction of PCBs

Industrial waste treatment for the power industry

Vichem has the engineering expertise to propose to our clients either a turnkey system, or a supply on the basis of design studies, crucial equipment and assistance for start-up and commissioning.

Our full range of services includes consulting, expertise, on-site audits, inspection, maintenance, training, retrofitting and debottlenecking, both for new plants or the upgrade of existing ones.

Centralized petrochemical waste treatment

Vichem provides centralized petrochemical waste treatment to treat hazardous waste from oil and gas companies and refineries. Capabilities include:

- Downstream of steam cracking, production of ethylene, propylene, butadiene, ethyl benzene, polyethylene

- SBS, TDI, oily sludges, etc.

- Spent caustic soda, ethylene, butane, etc.

The technology Vichem uses for this type of waste treatment includes:

- Rotary kiln for all solid waste

- Static furnace for fumes and liquids, fitted with our Pulvaporizator®

- Production of steam for production of electricity

Destruction of PCBs

Old transformers and condensers contain polychlorobiphenyl (PCBs) or polychloroterphenyl (PCTs), used as electric isolators. Nowadays they have been replaced by synthetic oil.

PCBs are hazardous compounds, classified as persistent organic pollutant (POP) which must be destroyed with care, together with any element which has been in contact with PCBs.

The destruction of PCBs takes place in the following steps:

- The transformers are emptied of their PCBs

- They are then dismantled and cut up into pieces

- These pieces are decontaminated inside an autoclave by means of a solvent, changed every three months

- Copper and scrap steel are recycled

- The PCBs are destroyed in a thermal oxidizer fitted with our Pulvaporizator

- Steam and HCl acid solution are recovered

Four references for pure PCBs:

- Séché (Trédi) in St Vulbas, France: 800kg/hr PCBs

- Arkema (Atofina) in St. Auban, France: 2,500kg/hr PCBs

- Monsanto in Anvers, Belgium: 300kg/hr PCBs

- Anwil in Wloclawek, Poland: 1,100kg/hr PCBs

Thermal oxidation system

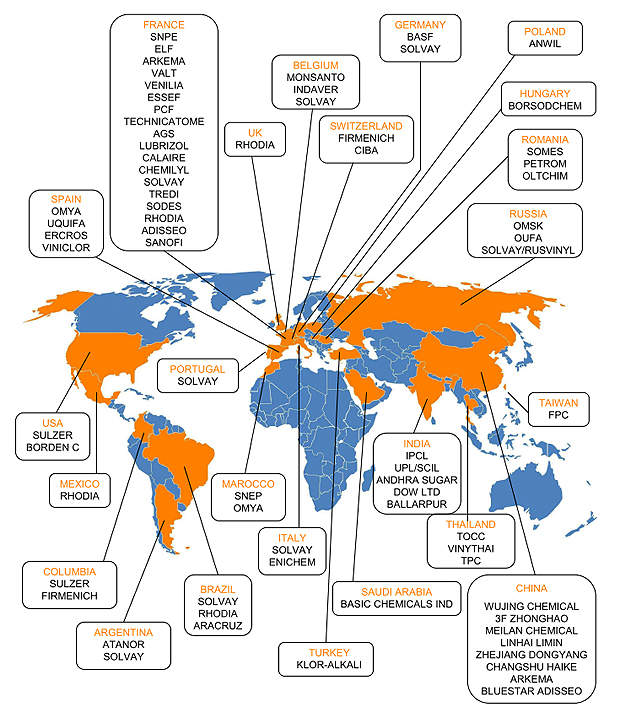

Vichem has become a leading supplier of advanced oxidation systems to destroy gas, liquid and solid waste. We are specialized in hazardous and very hazardous waste, mainly chlorinated waste and fluorinated waste.

We have developed and patented a specific low dioxin, low NOx burner for such applications: the Pulvaporizator, a revolutionary design of the oxidizer, atomizes and vaporizes the waste in one single step. Independent tests, performed on site, have proven that this unique thermal oxidation system enables a destruction and removal efficiency (DRE) of more than 99.9999%, with stack emissions well within environmental norms. Dioxins levels are lower than 0.005ng/Nm³.

Our units are often designed for thermal energy recovery through the production of steam, and/or recycling of compounds such as hydrochloric acid solution, pure anhydrous HCl gas, or fluorohydric acid.

Applications include:

- Centralized waste treatment

- PVC, VCM, EDC, ECH waste treatment

- CTC decomposition

- CDM projects: HFC23 abatement, SF6 destruction

- PCB destruction

- Treatment of refinery sludges