WIROMET is a well-known and experienced manufacturer of high-quality devices for the power generation and mining industries. We belong to a small group of manufacturers of steam turbine blades and other steam turbine flow system parts. In over 50 years we have acquired much experience in the field of production technology.

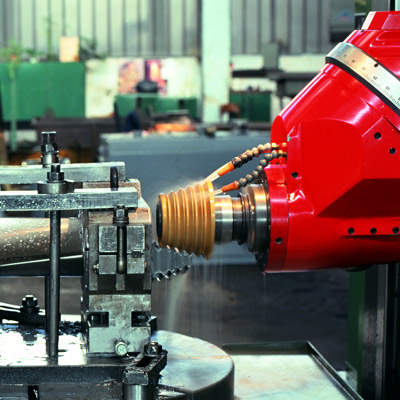

Blades and steam turbine flow system parts

WIROMET has the capacity to produce between 40,000 and 60,000 blades a year with dimensional scope from 20mm to 1,000mm (overall length). We produce our products on the basis of our own or customers’ documentation. Our engineers are prepared to restore and develop technical documentation based on measurements of new, used or even partially damaged parts. Their knowledge and experience guarantees the most appropriate selection of construction materials for the required working conditions.

Steam turbine / compressor rotor and stator blades, and blade-rings and rims

We offer rotor and stator blades for steam turbine and axial compressors as well as complete blade-rings and blade rims for steam turbines, consisting of the following:

- Steam turbine blades: rotor blades, guide vanes, nozzles and welded blade segments

- Steam turbine flow system parts: block locking pieces, lock blades, shrouds, locking pins, shifting and absorbing dumping wires, welded nozzles, welded diaphgrams, inverting rings, and interstage and final turbine labyrinth seals

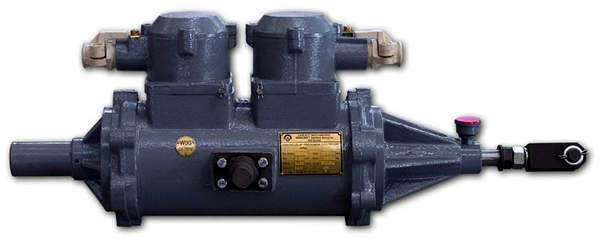

Plunger pumps, pumping engines and devices, couplings and actuators

WIROMET’s mechanical department produces parts mainly for the mining industry and can offer plunger pumps, pumping engines, high-pressure pumping devices for water-jet cleaning, industrial fluid couplings and electric actuators.

Steam turbine flow system parts and components

A main area of WIROMET’s enterprise is manufacturing parts, details and components, and other elements according to technical documentation worked by our designers or provided by customers.

Flow system part replacements

WIROMET provides engineering replacement services. We are able to work out documentation on the basis of measurements of supplied parts. For this purpose, we use modern techniques for measuring (coordinate machines and 3D scanners) and are able to identify and submit a detailed analysis of the master piece material in our laboratory. The data obtained in the process of measuring and testing systems is treated using CAD/CAM software.

Analysis of steam turbine flow system parts

WIROMET offers the implementation of strength and modal analysis of steam turbine flow system parts. For this purpose we use MSC FEA applications, which are based on their performance in PATRAN visualizations and calculations using NASTRANA modules.

Heat treatments

WIROMET provides a range of heat treatments for steam turbine blades and steam flow system parts, including annealing, hardening, tempering and induction hardening.