Everest Sciences produces the most efficient turbine inlet cooling systems available on the market today with the highest return on investment. Our patented indirect evaporative hybrid process improves the engine power output while reducing its heat rate.

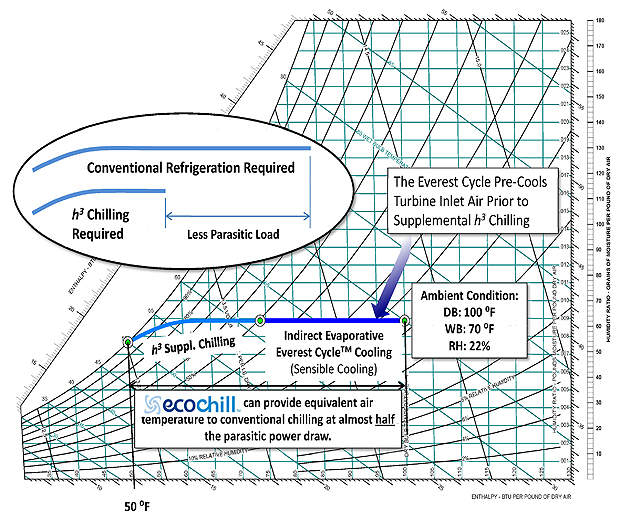

Our innovative technology filters and cools air lower than conventional evaporative methods while consuming similar parasitic power loads and provides chilled air equivalent to refrigeration while only consuming approximately half the power of a refrigeration system. The fully integrated solution ships from the factory complete, simplifying and expediting the installation process.

Indirect evaporative turbine cooling systems

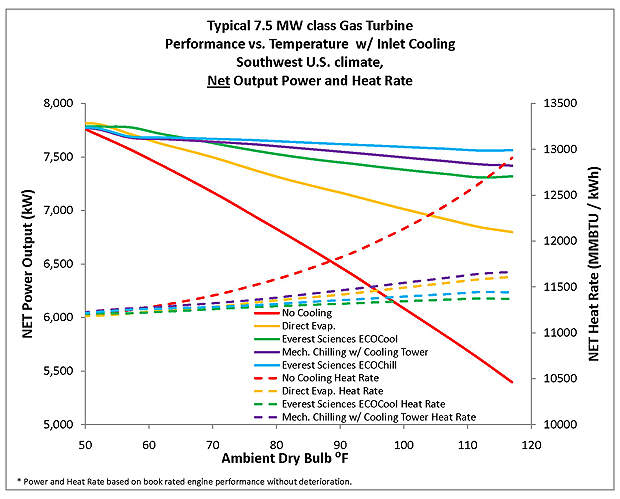

Gas turbines lose performance as ambient temperatures rise. This is most noticeable in the summer, when power is often needed most. Cooling the turbine intake air temperature improves engine performance. While various inlet cooling methods exist, Everest Sciences takes inlet air cooling a step further.

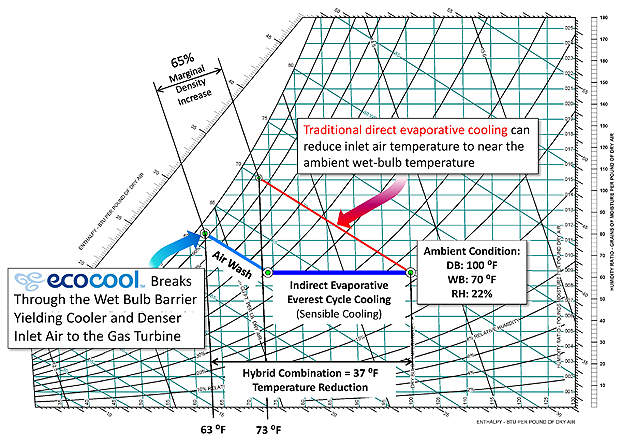

Unlike conventional solutions, Everest Sciences’ indirect evaporative cooling does not introduce moisture into the gas turbine’s primary airflow. Instead, evaporation occurs in a secondary air stream, which in turn cools the primary air. The result is an ultra-low power-consuming inlet air chilling process without the risk of compressor section fouling often associated with inlet air contamination of water-borne minerals.

Everest Sciences’ proprietary technology can increase gas turbine hot-day-available net power by as much as 40%, while reducing heat rates by 15% compared with un-cooled gas turbines. With today’s power requirements, rising fuel costs and increased awareness of emissions, the Everest Sciences solution has clear benefits for gas turbine users.

Water-based turbine inlet cooling system

ECOCool is the most efficient water-based turbine inlet cooling system available, helping operations increase turbine power output and improve engine efficiency. ECOCool combines the effectiveness of indirect evaporation Everest Cycle cooling and air washing. This hybrid process supplies inlet air temperatures below ambient web-bulb with a parasitic power load similar to conventional evaporative methods.

Not only does the ECOCool water-based turbine inlet cooling system provide cooler inlet air; it also yields inlet air with lower absolute moisture content. The result provides greater inlet air density than any competing evaporative technique.

Fully integrated chilling system for turbines

ECOChill is the first fully integrated chilling system with lower parasitic loads than conventional refrigeration techniques. Specifically designed for turbine inlet air operations, ECOChill improves the efficiency and performance of gas turbines. Unlike conventional refrigeration packages, ECOChill reaches target inlet air temperatures with substantially lower parasitic power draw.

The result is more net turbine power output and better net engine efficiency leading to increased revenue at a lower cost. The ECOChill fully integrated chilling system finally brings the benefits of inlet air chilling to small and medium-sized gas turbines.

Fully integrated water-based turbine inlet cooling system

Hydro-FlexCool is the first fully integrated water-based turbine inlet cooling system for safe use with contaminated or brackish water. The Everest Sciences Hydro-FlexCool is an inlet-air cooling system specifically designed for use with poor-quality water without compromising the turbine’s intake air.

Building on the effectiveness of the indirect evaporation Everest Cycle, Hydro-FlexCool provides cooler inlet air to the gas turbine while preventing brackish or reclaimed water from coming into contact with the inlet air stream.

Now locations that do not have access to high-quality water can achieve efficient inlet air cooling without expensive water treatment.

Advantages of Everest turbine inlet cooling systems

Everest systems offer many advantages:

- Allows gas turbine to produce greater net power output than any other competing turbine inlet cooling methods

- Incremental power provided at substantial reduction in emissions

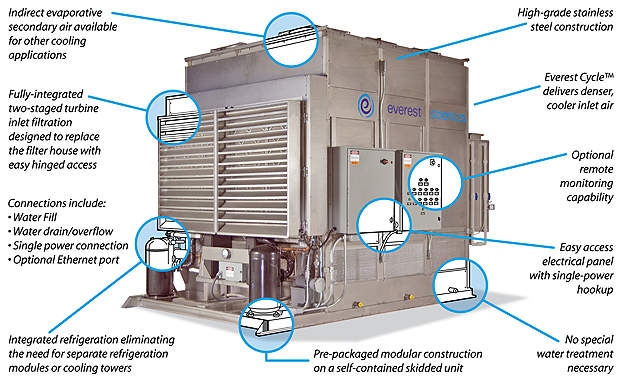

- Fully integrated and engineered systems that are factory pre-packaged and shipped completely functional to minimize field installation efforts and turbine down-time

- Single-source solution provider with technical staff to support product offerings

- Highly reliable and redundant design that offers benefits with low operational and maintenance costs

- Operationally simple and not requiring additional operational technical manpower requirements

- Proven and mature technology in operation on gas turbines located in the US

- Stabilizes power production irrespective of ambient climate conditions

- Controls can integrate into existing DCS system

- System requires substantially less to no treated water (de-mineralized/de-ionized) relative to other technologies

Reliable turbine inlet cooling systems

Everest Sciences turbine inlet cooling systems offer incredible reliability. They feature a mechanically simple design with few moving parts (reliable fans and pumps and industrial-grade components for long life), and single failures have a small effect on overall system performance. Routine maintenance can be safely performed while the turbine is running and the turbine still operates when the Everest Sciences unit is not operating.