CKD Blansko Holding has been producing water turbines since 1904. Over 110 years we have built a strong reputation among suppliers of hydraulic power plant technologies throughout the world. A century of experience has proven our quality and the ability to meet our customers’ most demanding requirements, whether in the efficiency of our machines or in environmental standards.

Our company programme involves manufacturing a range of water turbines (large hydro / small hydro) and hydro mechanical equipment (spherical valves, butterfly valves and other valves). We also run a water machinery research institute. Our years of experience in the field of water turbines enable us to offer turnkey projects of very high quality.

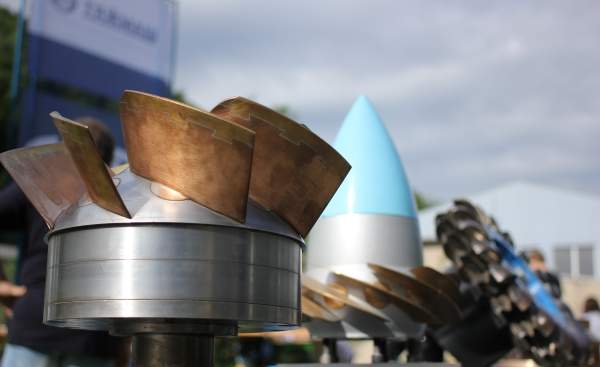

Water turbines

CKD Blansko Holding has expertise in manufacturing and overhauling all types of water turbines, including:

- Francis (1904-2013): 5,700MW total capacity

- Kaplan (1918-2012): 5,300MW

- Francis reversible (1936-2012): 5,900MW

- Pelton (1936-2007): 1,700MW

- Deriaz (1974-2005): 532MW

Hydro valves

In addition to water turbines, we also manufacture all types of valves. Since 1950, CKD Blansko Holding has produced more than 1,100 different models of valves. In Autumn 2007, a new company, CKD Blansko Small Hydro, was established and continues to manufacture water turbines and hydro mechanical equipment for small power stations. The company specialises in turbines with output between 200kW and 12MW. CKD Blankso Small Hydro’s experts have many years of experience in the water turbine industry.

Turnkey water machinery projects

CKD Blansko Holding is focused on turnkey projects, new installations, upgrades, refurbishments and overhauls. We provide our own specialists, because we are aware that knowledge of modern technology is essential in successfully fulfilling the customer’s needs.

We carry out each project in seven key steps. The first step is hydraulic research; thanks to our own water machinery research institute, we are independent of suppliers and can perform this first step with maximum efficiency. The second and third steps involve the design department and the department focused on special process specification. The fourth step is production, closely tied to manufacturing and testing. The fifth and sixth steps take place at the project destination, where we carry out workshop assembly and site erection. For the final step we commission products and train personnel. At each step we concentrate on controlling and evaluating the process in order to avoid mistakes.

About CKD Blansko Holding

CKD Blansko Holding, a.s. has been a member of the JSC Tyazhmash Group since 2010. Plant Tyazhmas in Russia was founded in 1941, and since then Tyazhmash has become a global leader in heavy, power and transport engineering. The connection between CKD Blansko Holding and JSC Tyazhmash guarantees quality for all offered products and services.