For almost 100 years our customers have demonstrated their trust in us. This trust, and the long-term relationships we have developed with our clients, as a result, has greatly contributed to the development of NTP. We are a leading national supplier of electroceramic components, with a substantial and ever-increasing export share. Our strengths are competence, product range, quality and adaptability.

Low, medium and high-voltage ceramics

NTP has a wide product range that allows it to satisfy many market segments. This ability has increased exports significantly in recent years. Today the company’s products are exported to more than 30 countries around the world. The product range covers low, medium and high-voltage ceramics.

Ceramic insulators

NTP’s range includes ceramic insulators for all types of lines, substations and apparatus. Although insulators are manufactured according to IEC standards, other national or international types can be supplied as well. NTP’s product range includes:

- Pin insulators

- Line post insulators

- Post insulators

- Hollow porcelains

- Insulators for DC-electro filters (ESP insulators)

- Ceramic welding backing

- Insulation beads

- Epoxy resin insulators

- Various press bodies

- Composite insulators

ISO-certified manufacturer of electro ceramic components

As NTP sees it, quality is not only related to the products themselves but also to the whole process – from the quotation stage through order handling, design, manufacturing and to after-sales services. Since 1982 the company has had an independent QA department that secures high-quality work in every department. In 1994 NTP was awarded the NSEN ISO 9001 certificate. This guarantees high-quality products and states strict requirements regarding development, design, manufacturing, installation and servicing.

Standard and custom electro ceramic components and insulators

In order to focus on its customers’ needs, NTP has the following philosophy to ensure customer satisfaction:

- Respond quickly to all enquiries

- Offer both tailor-made and standardised solutions

- Offer price-competitive products

- Offer short and reliable delivery times

- Deliver high-quality products

- Perform excellent after-sales service

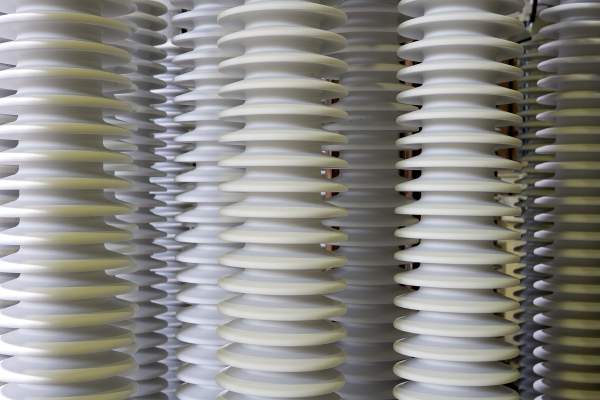

Manufacturing of electro ceramic components

NTP’s products require different ceramic materials. The company uses a wide range of substances, fluxes and fillers in order to fulfil its customers’ technical requirements. In order for NTP to offer a wide range of products, several different production methods are used.

Today the company uses the wet process manufacturing method, slip casting, dry pressing, extrusion and turning as forming methods. The total output capacity is approximately 3,000t of porcelain per year.