Tuboly-Astronic provides machinery for the transformer industry such as core cutting and stacking, as well as coil winding.

Core cutting for the power industry

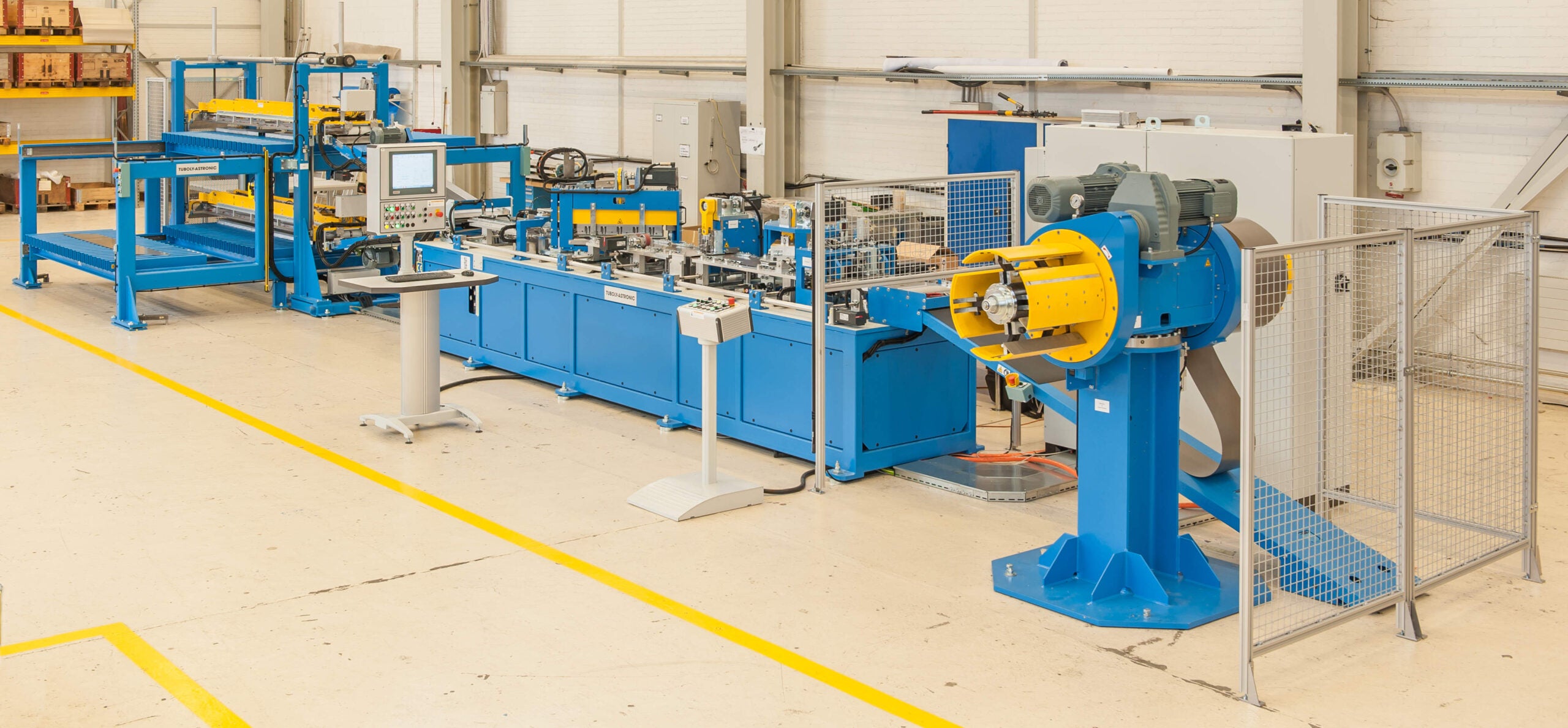

Tuboly-Astronic provides core cutting machinery for a wide range of transformers.

The company’s core cutting lines help to optimise core production. Different levels of automation are available depending on the customer’s requirements,

Tuboly-Astronic also supplies specific machines for chokes (90° cut sheets) and shunt reactors.

Customised and standard core stacking systems

Core stacking systems are often customised so they are aligned with the task but several standard solutions are also available from Tuboly-Astronic.

Core stacking includes the automated production of e-cores. This is available in-line with the cutting machine or independent of the cutting process, starting with piles of sheets.

With this solution, repetitive activities are overseen by the machine, guaranteeing repeat accuracy and maintaining health and safety levels.

Coil winding machines

Tuboly-Astronic supplies low-voltage (LV) foil winding machines that come with widths up to 1,600mm, cold pressure or tungsten inert gas (TIG) welding.

Flexible software, simple programming, and operator guidance are also available in addition to automated stops to insert lead-out.

Wire winding machines with strip and / or full width insulation are available with automated stops for taps and cooling ducts. The semi-automated winding process ensures top quality manufacturing of products.

The company also provides vertical winding machines designed for the production of transposed disc windings with single or continuously transposed conductors (CTC). The software supports the entire winding process and instructions and information for the operator are displayed on the screen.

The bending is executed automatically at the calculated positions which reduces production time. These machines are available in pit or floor variants.

Horizontal winding machines come with radial and axial pressing units, and conductor brake systems for gentle processing of insulated conductors to meet the stringent requirements of MRI coils.

Special machines

Winding machines for supra conductors are available. These perform with the highest winding accuracy, constant wire tension and operator guidance.

Bushing winding machines for production of insulation bodies for oil-impregnated paper (OIP) or resin-bonded paper (RIP) condenser bushings made of crepe or kraft paper, and aluminium foil, equipped with state-of-the-art heating systems for moisture reduction and automated aluminium foil cutting and inserting system, as well as real time diameter measurement.

Corrugated fin panel production lines feature automated processes, an ergonomic set-up system, and flexible software, providing accurate and efficient folding, shearing and seam welding.

Tuboly-Astronic also has options for spot welding, reinforcement strips, embossments, and rod magazines.