FELUWA Pumpen has a company history stretching back nearly a century. Since 1931, it has been focusing on the design, development, production, as well as sales and after-sales service of pumps, to meet a wide range of challenges.

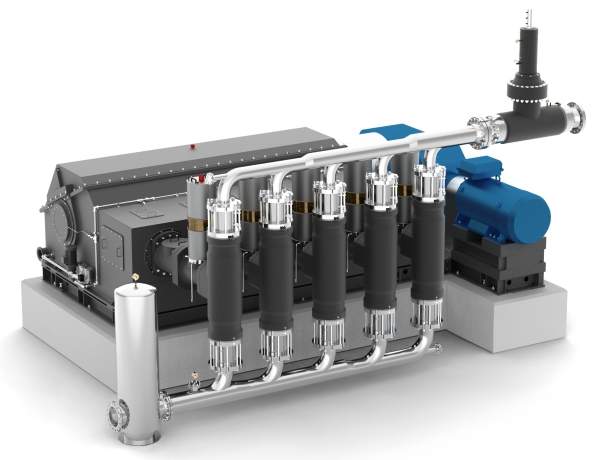

Double hose-diaphragm pumps

At the heart of the pump are two hose diaphragms, which are arranged one inside the other and fully enclose the linear flow path of the conveyed fluid. They create double hermetic sealing from the hydraulic drive end of the unit. Both hose diaphragms are triggered by the piston from hydraulic fluid. Synchronised with the piston stroke, they are subject to a pulsating action, comparable with that of a human vein.

One of the distinct advantages of this design is the linear flow path, so that it is especially effective at handling aggressive, abrasive and solids carrying fluids. In the unlikely event that one of the hose-diaphragms fails, the fluid inside will not come into contact with the casing. As a result, expensive special materials, chemically compatible with the fluid, can be avoided.

Coal-fired power plants

Typical applications of MULTISAFE pumps in the power industry include:

- Hydrotransportation of coal to power stations

- Dense ash pipeline disposal from power stations

- Feeding of lime milk and disposal of gypsum slurry in flue gas desulphurisation systems.

FELUWA MULTISAFE double hose-diaphragm pumps ensure the energy-efficient hydrotransportation of coal slurry to power stations, as well as dispose of fly and bottom ash at the maximum concentration. This allows for quick solidification and recultivation.

MULTISAFE pumps are specified for low and high-pressure duties within the power industry and have proven their outstanding reliability in hundreds of installations.

For the handling of highly dense slurries, pastes or products that tend to settle, the working principle of FELUWA MULTISAFE pumps is literally turned upside down, which means that the flow is directed from the top to the bottom of the pump. The so called ‘downflow configuration’ avoids the settling of heavy solids (such as bottom ash) within the pump. Both upflow and downflow configurations offer high reliability and availability at a minimum cost to the owner.

Pumps for coal gasification plants

- Low-pressure pumping of coal slurry from mill discharge to coal slurry tank

- High-pressure feeding of coal slurry into gasifiers.

To a large extent, the efficiency of coal gasification facilities depends on the availability and reliability of the pumps that feed the coal slurry into the gasifier. As a general rule, positive displacement pumps are used for this purpose. Apart from maximum availability, these units have to ensure minimum pulsation and maximum accuracy of the feed range. More than 80% of gasifiers around the world are fed by double hose-diaphragms process pumps or hose diaphragm piston pumps, respectively.

Double hose-diaphragm pumps with check valve design

The check valve design is another technological feature that is essential for gasifier feeding. The pumps are equipped with special double-ball valves. In the short term, should a particle get jammed between the ball and the valve seat result in valve leakage, the second valve ensures effective sealing; this prevents medium backflow and a resulting loss of volume. Big size valves are of top-entry design and provided with hydraulically activated quick change systems, so that complete valve assemblies can be removed within a matter of minutes.

In addition, check valves are subject to permanent condition monitoring by means of acoustic sensors, which are fixed to the outside of the valve casing and not in contact with the slurry. The sensor is capable of detecting leaks, even if the loss of output is still less than 1.5 %. This helps avoid a drop in energy resulting from increased pump speed.

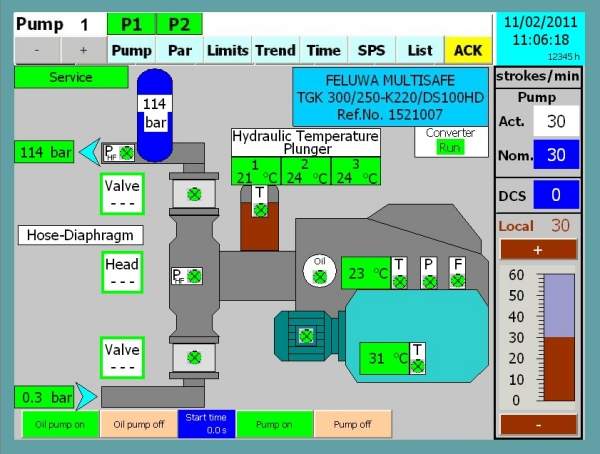

Diagnostic systems

FELUWA supports the redundant nature of MULTISAFE double hose-diaphragm pumps through an overall diagnostic system. Touch panels are integrated into the control panel, which provide the operator with information on current operating conditions, as well as the health of the key parts.

The company offers a human-machine interface, with the full integration of pump diagnostics into industrial control systems, as well as a web-based service option.

MULTISAFE hose-diaphragm pumps are available for flow rates of up to 1,000m³ an hour, as well as pressures up to 320 bars.