POWER ENGINEERING has a decade of experience in the field of mechanical engineering and energy consulting.

Our experienced staff and cross-disciplinary fields of application make POWER ENGINEERING the partner that gives clients all the skill and support needed to manage and complete a project.

POWER ENGINEERING operates a turnkey service, which includes comprehensive services such as consulting, estimated analysis, feasibility study, working planning, plant installation, start up and commissioning, and all the necessary technical documentation.

Each project follows a series of procedures that outline the responsibilities and action plan for the coordination and completion of duties related to the implementation of projects.

The application of this method ensures that:

- Project activities are planned and carried out in a controlled manner

- The control mode of the project is identified

- Data that enables clients to monitor the progress of the project has been collected

- Checks, inspections and reviews in the development phase of the project are completed

- Validation is performed at the end of the project

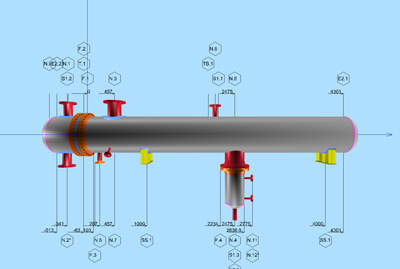

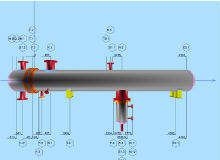

Heat exchangers and pressure equipment design

POWER ENGINEERING has considerable experience regarding pressure vessels and heat exchangers. In this field, we can perform the detailed design of individual devices (vessels, columns, reactors, exchangers and tanks) or entire plants. Our staff can also design piping, preparing the piping and instrumentation diagram (P & ID), and provide isometric views and bills of material.

POWER ENGINEERING can perform all the necessary calculations concerning pressure and stability of the apparels and the steel structures, in accordance with the most important international codes.

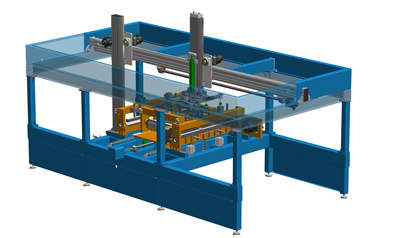

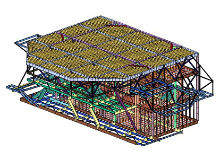

Industrial engineering

POWER ENGINEERING can provide comprehensive engineering services for industrial plants, from construction drawings to the design of steel structures, industrial machines and entire plants.

A few examples of POWER ENGINEERING’s work include:

- Metal framing: steel structures, pipe racks, ladders, platforms and supporting structures

- Inert materials treatment plant, recycling plants: conveyer belts, vibration ducts, vibration screens, loading hoppers and screw conveyors

- Oil and gas, water treatment and chemical plants

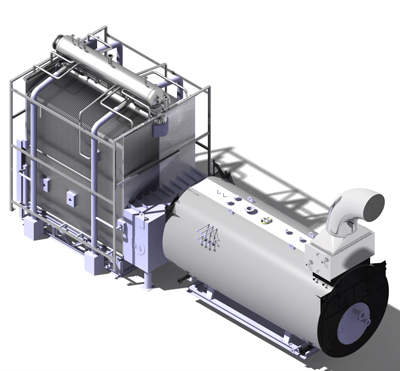

- Energy production plants and heat recovery systems

Thanks to our ten years of experience in the field, POWER ENGINEERING has achieved a detailed knowledge on product engineering and industrialisation for many ‘high technology products’, such as hot water and steam boilers, solar panels, heat exchangers, cogeneration machines, crushers, industrial automation machines and self-propelled machines for crushing and sifting.

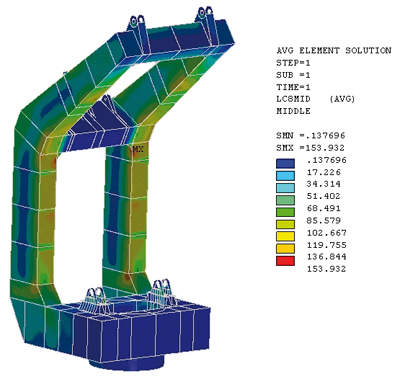

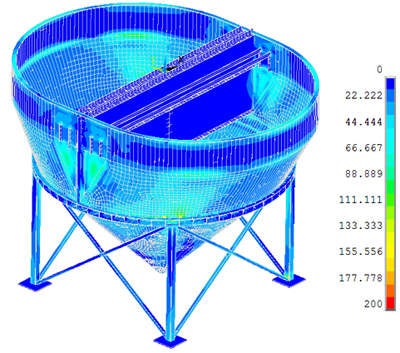

Structural analysis

POWER ENGINEERING’s structural engineers are capable of providing structural calculations, verification of stability and resistance to fatigue, FEM structural and fluid dynamic analysis.

All information is provided in accordance with the most important international codes (ISO, EN, ASME, etc.).

Fields of application include:

- Steel structures for civil and industrial use

- Structures for material transfer and storage plants

- Pipe rack with steel or mixed (steel and concrete) structures

- Ship loader and unloader machine structural parts

- Mechanical machine parts and mechanical components

Technical documentation

POWER ENGINEERING is able to produce all the required documentation for the technical/commercial managing of machines and plants that have been planned both in and out of the firm.

Our staff can also draft risk analyses and documentation for CE certification for user and maintenance manuals, technical files and functional enclosures, in addition to the creation of exploded drawings for after-sales and spare parts management.

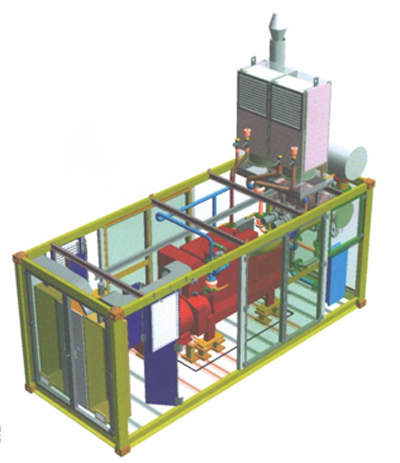

Cogeneration plant installation

POWER ENGINEERING can also provide a thorough consulting service for firms that intend to carry out and install cogeneration plants.

Our staff conducts energy analysis processing by recording consumption data of electrical and thermal energy in the field, and then creating the technical and economical evaluation necessary for installing a plant, through the combination of annual money-saving calculations and the payback-time evaluation. The evaluations also take into account permissions and license fees, installation, engineering and supervision of works, and start-up, testing and commissioning of the cogeneration plant.

Industrial supply

Thanks to our collaborations with specialised mechanical workshops, POWER ENGINEERING is able to meet the complete supply needs of its customers. Here are some examples of the devices we are able to supply:

- Pressure equipment: heat exchangers, economisers, fired and unfired steam generators

- Prefabricated boiler works components

- Prefabrication and industrial piping assembling

- Fermentation fluid autoclaves, drinking water filters, mixer machines

- Construction and assembling for metal framing and metal structured works

- Pipe and profile metal working, bending and welding; sheet and plate calendaring

About POWER ENGINEERING

POWER ENGINEERING was founded on the need of the two founding partners to create a large and structured working group to provide a real service centre with highly technological content.

Thanks to the experience gained by the partners in the fields of design and energy since 1990, POWER ENGINEERING has a wide expertise in the design of machines and industrial equipment, automation and energy management systems.