Olympus Corporation is an international company specializing in optics, electronics and precision engineering. Olympus operates in the industrial, medical and consumer markets, providing a leading portfolio of innovative test, measurement and imaging instruments. Olympus testing technologies include remote visual inspection, microscopy, ultrasound, phased array, eddy current, eddy current array, X-ray fluorescence and diffraction, high-speed video, and optical metrology.

Ultrasonic flaw detectors

Our products include ultrasonic flaw detectors and transducers that are PDI-qualified for ferritic and austenitic welded piping, weld overlay, and dissimilar metal welding. The EPOCH flaw detector family is constantly evolving to service the industry with innovative, high-performance equipment.

Automated ultrasonic equipment for power generation applications

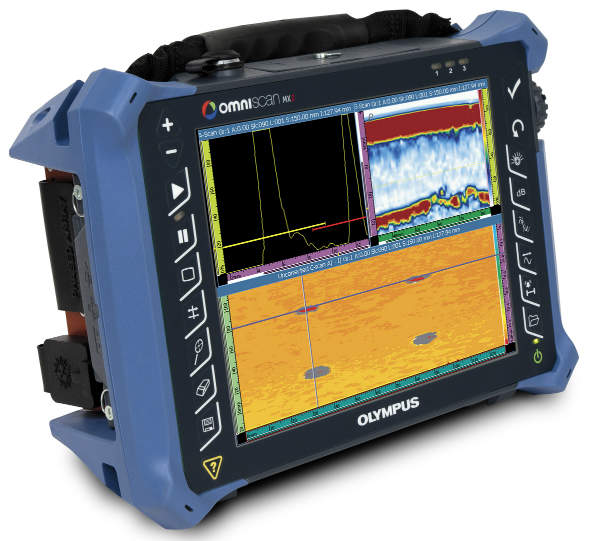

We offer conventional and phased array ultrasonic equipment capable of tackling NDT challenges such as dissimilar metal welds and weld overlay. The OmniScan MX2 offers a wide range of phased array configurations and software tools like weld overlay display.

The Tomoscan FOCUS LT is a fast, powerful, reliable, and scalable phased array inspection instrument designed to be the keystone of any advanced NDT solution. The OmniScan MX UT is an excellent tool.

Ultrasonic testing solutions for weld inspection

Olympus NDT has developed a series of solutions for welded pipe inspection. These solutions, which meet the most stringent requirements of the power generation industry, are applicable to carbon and stainless-steel piping.

The COBRA scanner was designed for small-diameter thin-wall pipes in low clearance applications, whereas the CHAIN scanner is capable of handling a wide range of diameters, and can be used in combination with TOFD, phased array, and pulse-echo transducers.

In addition to custom probes designed for specific applications, Olympus offers a large selection of phased array probes, including dual-matrix array probes, which are ideal for more demanding weld inspections.

Eddy current and eddy current array testing equipment

We offer eddy current equipment and probes that meet the most stringent requirements of the power generation industry.

From pencil probe inspections to conventional eddy current flaw detectors we offer reliable products for the most demanding applications.

Industrial videoscopes

Olympus has a full range of industrial videoscopes designed for the inspection of turbines, wind turbines, steam generators, backup generators, condenser tubes, and other difficult-to-access areas. Olympus NDT’s long scope product line has recently been expanded to include entry-level models at 10m and 20m, in addition to the brand new, innovative technology found in the 30m IPLEX YS. Many of the Olympus videoscopes have a fiber-free design, making them more durable in radiation contaminated environments, and built to withstand some of the most demanding inspection environments known.

X-ray fluorescence testing equipment

Material tracking and confirmation is critical to the production and maintenance of power generation facilities. Relying on material reports from suppliers is never a fail-safe procedure; secondary on-site verification is essential. Olympus Innov-X handheld XRD analyzers provide non-destructive chemistry analysis and positive grade identification of metal alloys anywhere, whether at incoming or in on-site facility inspections, in just a matter of seconds.

See also: Olympus Corporation – Test, Measurement and Imaging Instruments