BarkerBille designs and manufactures a variety of highly efficient fans and blowers for industrial power applications, both onshore and offshore.

Fans for dryers, boilers, filters and chimneys

We supply high-efficiency items for the power industry, with items including:

- Mains supply fans

- Extraction fans

- Induced or forced draft fans

- Combustion fans

- Boiler fans

- Fluid bed exhaust fans

- Cooling air fans

- High-pressure blowers

- Fans for clean air supply and general ventilation

Fans can be supplied as ATEX fans, fulfilling applicable standards and regulations at all times.

Industrial fans for power plant operations

BarkerBille has several years of experience in manufacturing industrial fans for the power and incineration business.

The fans are used in processing plants in power, heating and CHP stations, as well as incineration plants and waste-to-energy facilities where biofuel or fossil fuels such as petroleum, gas or coal are used.

Traditional incineration plants produce energy for a large number of houses, with complex buildings and processes often requiring different types of fans.

All of BarkerBille’s fans meet important efficiency requirements.

Our fans help to deliver combustion air and their performance is determined by the boiler’s current requirements for air during the incineration procedure. The volume of air is regulated by a damper on the fan’s suction side or by a frequency converter.

Waste gases are fed through a heat exchanger before being released into the atmosphere. Their subsequent drop in temperature means that natural chimney draughts cannot be formed, signalling the need for the flue gases to receive assistance from the flue gas fan.

The flue gas fan forms a partial vacuum in the boiler to minimise the risk of flue gases being released into the atmosphere.

Primary and secondary air fans

Among the type of fans which we provide are the primary air fan, for transporting air from the boiler house to the grates, and the secondary air fan, which carries air from the waste bunker to the secondary air nozzles.

Also available is the cooling fan, taking air from the boiler house to the cooling inlets on the feeding pusher and grates, as well as the ID and FD fans.

These are installed after the flue gas cleaning plant, allowing the flue gas to be transported to the chimney through the flue gas condenser, therefore avoiding operation with flue gas in a saturated condition.

Seal air fans and recirculation fans are available, too.

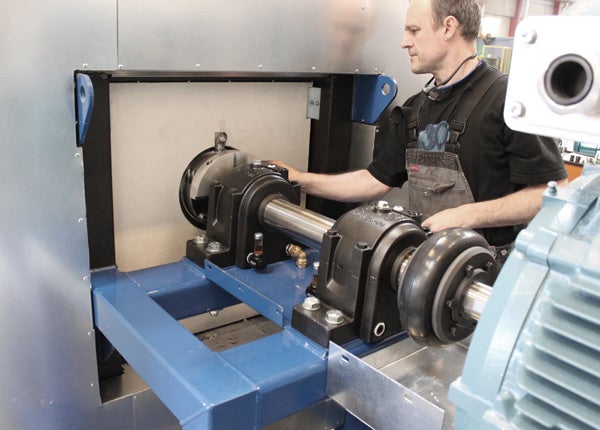

High-quality centrifugal fans for power facilities

BarkerBille high-quality centrifugal fans are used in power plants worldwide and industrial applications such as dryers, boilers, filters and chimneys.

The centrifugal fan programme typically covers airflows from 1,000m³/hr to 300,000m³/hr and pressures up to 35,000 pa (10psi).

Customised fans for power plants

Through decades of experience in the power industry, we have earned a reputation for providing plants with critical parts, supporting project engineers and buyers in reaching the optimum solution.

The needs of each application are different and therefore, we decide on the materials, noise and energy efficiency when building our fans.

BarkerBille offers a wide range of fan accessories and customisation such as:

- Access doors

- Acoustic booths and silencers

- Automatic lubrication

- Base frames

- CIP systems

- Cooling discs

- Drains

- Flex connections

- Flanges and counter flanges

- Guide plates

- Inlet vane control

- Inlet throttle valves and special inlets

- Noise and heat insulation of fan

- Protection net

- Vibration dampers

About BarkerBille

BarkerBille has been supplying high-efficiency fans for various industries over the past 50 years. Production takes place in Denmark and China, where the high standards for which the company is so well-known are consistently met.

BarkerBille is a merger of Barker Jørgensens Maskinfabrik, B. Bille and Moldow’s fan department, which has resulted in a well-founded company, both economically and technically, specialising in industrial fans and related products.

Trusted and efficient designs are created by the company, using the fan-dimensioning software FanDim as well as 3D technology.

BarkerBille develops primary-welded constructions, which are produced in mild or stainless steel.