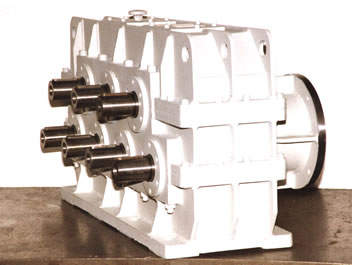

Kachelmann Getriebe supplies customised gears and gearboxes to numerous industries worldwide. Amongst the company’s customisable products you are sure to find gears and gearboxes with the drive and motion you are looking for.

Gears and gearboxes range

Kachelmann Getriebe’s range of special gears and gearboxes includes:

- Gearboxes up to 40t

- Spur gear units

- Bevel gear units

- Planetary gear units

- Worm gear units

- Indexing gear units

Customised gearboxes and drive units

As a producer of special gearboxes, Kachelmann is able to design and produce drive units that match each individual customer’s requirements.

Customised gears

Kachelmann’s range of special gears includes:

- Spur gears of up to 45 module, with diameters of 8,000mm

- Bevel gears of up to 21 module, with diameters of 800mm (also Klingelnberg-Zyklopalloid)

- Worm gears of up to 24 module, with diameters of 1,800mm

- Tooth racks up to of up to 16 module

- Chain wheels

- Gears that meet the DIN 5480 standard

Design, development, construction and production of gearboxes

Kachelmann has been providing global customers with high-quality gearboxes for four generations. Qualified engineers and workers ensure that the company meets its customers’ needs. The specialists from Kachelmann help to keep the costs of installations down by choosing the right gearbox for the right installation. Kachelmann gearboxes are designed for a maximum lifetime combined with minimal maintenance.

Depending on customer requirements, Kachelmann gearboxes can also be designed and produced according to special standards such as KTA or ATME norm.

Spare parts for gearboxes

Kachelmann do not only provide complete gearbox systems but also design and produce spare parts for existing gearboxes. The company’s team will support you from the order through to the delivery and assembly at your facility.

Maintenance of gearboxes

Gearboxes are the heart of an installation. Quality and the expertise in design, production and assembly are important points which influence the lifetime of the gearbox, and therefore also of the lifetime of your installation.

Continuous maintenance and service during the total lifecycle of a product ensures high productivity and high efficiency. Early checks and maintenance services can prevent a total shutdown of the facility, and therefore unnecessary and uncalculated maintenance costs.

Maintenance and service for Kachelmann’s products, from the date of delivery and installation at a plant, is carried out by qualified Kachelmann employees. This can include disassembly of the gearbox; regular check-ups; replacement of bearings, sealing and wearing parts; manufacture of new parts; assembly; test running; and painting. Kachelmann’s services are available 24/7 in an industry where every day counts.