Doosan Lentjes started business in 1928 and focuses on delivering proprietary technologies for circulating fluidised bed combustion, waste-to-energy and flue gas cleaning applications.

Doosan Lentjes started business in 1928 and focuses on delivering proprietary technologies for circulating fluidised bed combustion, waste-to-energy and flue gas cleaning applications.

Depending on customer requirements, Doosan Lentjes is a technology provider, which delivers full turnkey projects and cooperates with international EPC companies.

As a member of the global Doosan group, Doosan Lentjes has the financial strength and stability to offer and guarantee projects to be delivered on time.

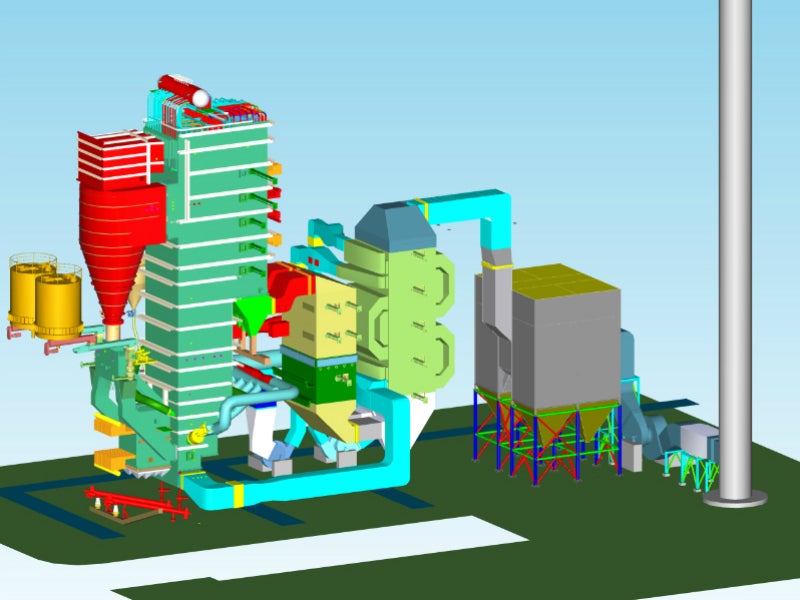

Circulating fluidised bed boiler solutions

CFB boiler technology allows maximum fuel flexibility for various fuel types with difficult combustion properties such as low ash melting temperature, low calorific value, high moisture or ash content.

Besides fossil fuels, the CFB boiler technology reliably and efficiently incinerates renewable fuels, including biomass, which gives customers the assurance to meet their economic and environmental goals.

The CFB process offers inbuilt emission control and SO2 released during combustion can be captured by adding limestone to the system.

The comparatively low combustion temperature of 850°C and the staged air supply also prevent the formation of thermal NOx. These features remain valid in conjunction with the broad fuel flexibility.

Doosan Lentjes draws on vast experience in the field of CFB technology, encompassing more than 110 units contracted around the globe to date.

Grate, combustion and flue gas cleaning systems for waste-to-energy applications

Doosan Lentjes delivers grate technologies, combustion systems and flue gas cleaning solutions for all waste incineration requirements. All solutions feature a tailor-made design safeguarding highly efficient incineration and energy recovery even when changing waste compositions and qualities.

With almost 80 units contracted around the world, which convert millions of tonnes of waste-to-energy every year, Doosan Lentjes has the experience to lead these kinds of projects to success.

Flue gas desulphurisation technologies (FGD)

Doosan Lentjes has a long tradition in wet and dry flue gas desulphurisation (FGD) processes. With almost 40 years of experience in air quality control systems, Doosan Lentjes has installed more than 50 dry and 110 wet FGD plants, including wet limestone or seawater absorbent applications.

The wet limestone FGD process has been specially designed to meet the requirements of high sulphur or largescale power plants. For facilities located near the coast, the seawater FGD system is a suitable alternative, which achieves the same desulphurisation results as the wet limestone process.

When it comes to the removal of multi-pollutants such as SOx, HCl, HF, as well as, hydrocarbons and heavy metals, the dry Circoclean® FGD process is most attractive. Customers benefit from a compact solution applicable downstream in different boilers fired with fuels, including coal, oil, biomass, RDF or domestic or industrial waste.

Doosan Lentjes selects the most suitable FGD process to ensure that the most stringent applicable emissions directives are being met.

Selective catalytic reaction DENOx technology

The selective catalytic reduction (SCR) process is a reaction of ammonia with nitrogen oxides on a catalyst. The nitrogen oxides present in the flue gas are converted into nitrogen and water vapour.

Applications in high dust (upstream of a filter) and low dust (downstream) have been realised, totalling a 35,000MWe equivalent installed capacity.

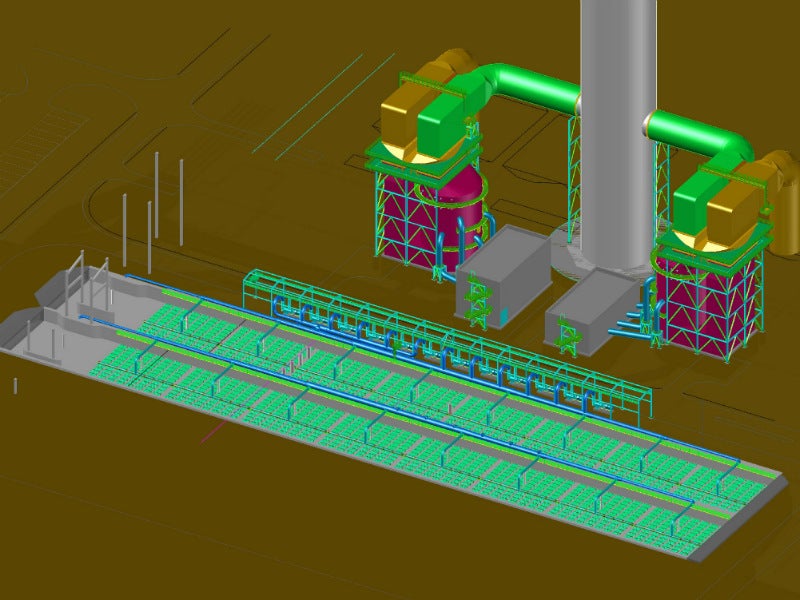

Electrostatic precipitators (ESP) and low-pressure pulse jet fabric filters

Doosan Lentjes can rely on the experience accumulated in one of the largest precipitator databases throughout the world due to the fact that over 6,000 electrostatic precipitators (ESP) have been built to date.

In addition to ESPs, it can also offer low-pressure pulse jet fabric filters operating at a very low air reservoir pressure, saving energy.