Solvina specialises in optimising plant control, creating dynamic performance of power plants and onsite generation plants. We work in areas such as nuclear, hydro, thermal, pulp and paper, steel, chemical and petrochemical.

Solvina focuses on using dynamic simulator technology in control design, tuning and commissioning. This means that thoroughly tested solutions can be put into operation quickly and economically. Solutions are delivered for different systems in power plants, aiming for optimum stability and efficiency in:

- Boiler control

- Steam net control

- Turbine control / island operation

- Generator control

- Protection

Solvina improves the performance of existing plants and ensures the right design in new-build and modernisation projects. Our process and power control experts design and implement superior systems and control for efficient and robust operations. We also have unique services for island operation testing and planning, as well as power plant simulators for engineering and operator training. Huge savings are achieved by decreasing outage time and energy losses. A key to success is also the holistic, multi-discipline approach used for projects.

Steam system control optimisation

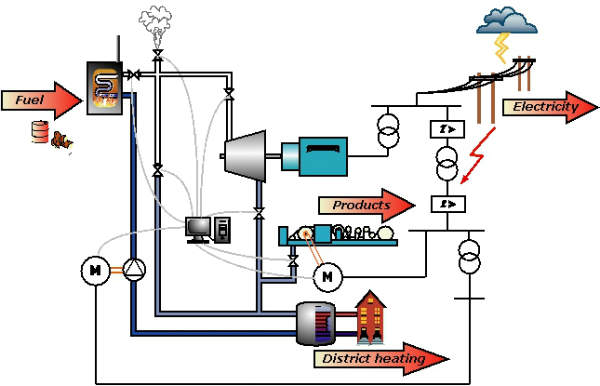

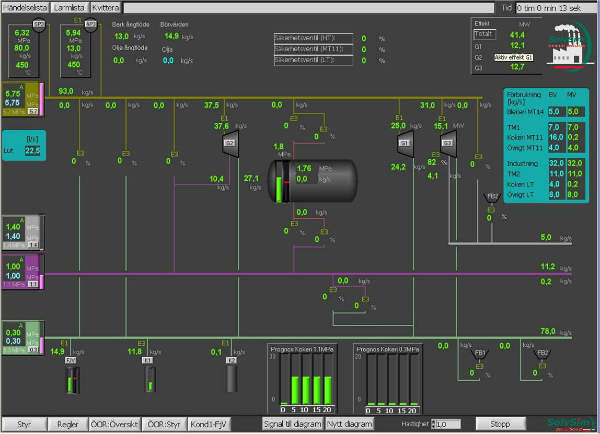

Solvina develops and improves the steam system control by the coordinating of boilers, bypass valves, turbines and steam accumulators. Our methods ensure the best possible process control for all critical operating conditions and events in the plant itself. We offer economical analysis packages to identify and suggest further improvements on a shared risk / profit basis.

Solvina has developed advanced simulator based methods to increase the availability and stability of steam systems in power and cogeneration plants. The steam system of an industrial cogeneration plant is far more complex than those of a conventional power plant as the steam consumption varies greatly, often momentarily, and there are several steam grids with different pressures. This requires expert knowledge when designing the process and its controls.

By developing control strategies and tuning parameters in dynamic simulators, Solvina achieves fewer disturbances and more efficient commissioning after planned outages. Simulation is used throughout the project process, from conceptual design and purchase, to fine-tuning, commissioning and training.

Turbine governor control and tuning for stable island operation

Solvina offers tuning and testing services to optimise the dynamic performance of governors and frequency control. The goal is to achieve more robust operations, resulting in higher availability and stability.

A turbine governor has many control modes and functions for protection. All these functions have an effect on the plant performance. Solvina optimises the control modes for best possible performance and also tunes limiters and protectors to allow dynamic performance, while maintaining protective functions.

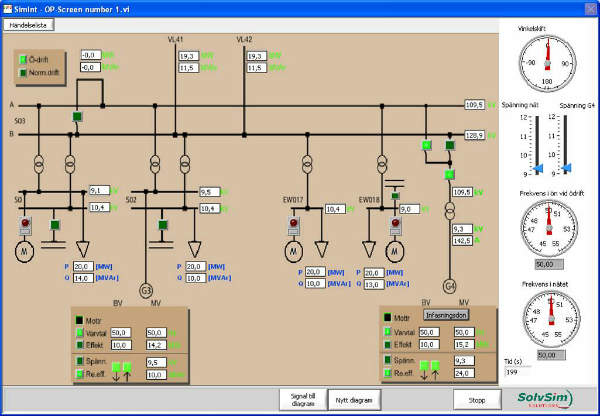

During power system disturbances and interrupted energy supply, a power plant can continue running if it can transfer to an island operation and if it hassufficient capabilities. However, as conditions can be tough and sensitive, islanding is complicated. Performing a black start can be even more difficult. Solvina has unique experience and knowledge of island and in-house operations. Our test methodology, using the real-time simulator SolvSim® Power Station, enables safe island and in-house operations testing and development.

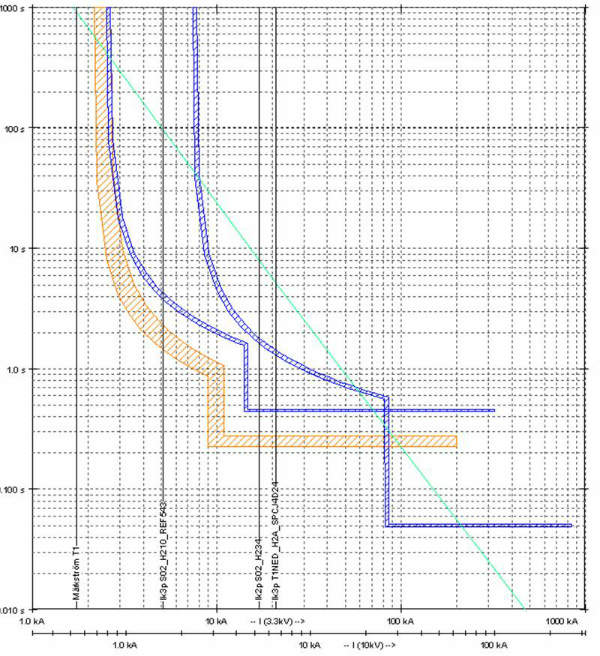

Testing and tuning of voltage controllers (AVR) and power system stabilisers (PSS)

The automatic voltage regulator (AVR) of generators has several control modes and modules for limitations and stabilisation. Solvina performs tuning for power system stabilisers (PSS) and AVR systems to meet grid code and local requirements. Dynamic simulation of the surrounding power system is performed to get the optimum result, with settings followed up in the commissioning phase. Our main objective is ensuring fast and stable control in every installation.

Operator training for improved control

Plant operation management is a critical factor for productivity, stability and plant efficiency. Solvina conducts training programmes for operation and maintenance staff to increase the understanding of plant behavior.

The main focus is to learn about functionality of the processes, control and systems, as well as physics governing their behaviour. Complex theory is explained in a practical and easy-to-understand manner, with training simulators used to visualise and verify the theory and enable training. The goal is that operators will be able to take faster and more accurate decisions based on advanced knowledge of the plant, achieving improved productivity and efficiency.

References:

- ALSTOM Power

- Westinghouse Electric Sweden

- Svenska kraftnät (National grid authority)

- Vattenfall Ringhals, OKG (nuclear power plants)

- Södra Cell, Billerud (pulp and paper)

- Eka chemicals, Akzo Nobel (chemical)

- Holmen, Iggesund Paper Board

- SSAB (Steel)

- Vattenfall

- E-On

- ABB Power Systems