Utility Oils has provided specialist services to the major suppliers within the electrical transmission industry for over 16 years. Until 2006 we were part of sector leader Lofthouse International, when continued success and growth resulted in us becoming our own company, concentrating exclusively on providing specialist oil reclamation, processing, transport and storage services, which we were known for, to our industry partners.

It’s all very well claiming to be the best at what you do but the reason our customers stay with us is because they know we have the resources to support those claims.

Oil reclamation extends unit life

Utility Oils mobile reclamation system restores transformer oil by removing acidity, sludge and soluble oil decay products with Fullers Earth treatment technology. When the treatment is complete, the reclaimed oil meets or exceeds B.S.148, the standard for Reclaimed Insulating Oil, with lower acidity and improved tan delta, interfacial tension, and oxidation stability.

The cellulose insulation and internal components of the transformer also benefit from the flushing affect of multiple passes of hot reclaimed oil, which helps remove decay products and sludge from surfaces.

Oil reprocessing services

We have the expertise, experience and innovative solutions to provide our clients with a quality, on or off-site oil reprocessing service to keep their transformers running smoothly, which is the most cost-effective way of maintaining the equipment and extending its life. We are also a registered tied oil trader and can offer purchase and disposal of used oil (dependant on condition). To complement this service we also continue to lead the sector with bulk oil transportation.

Transformer oil regeneration

The best process for reclaiming transformer oil is treatment using Fullers Earth. However, conventional reclamation units are costly to operate, requiring large amounts of Fullers Earth which must be disposed of and replaced after each use. Our oil Reclamation

System features high-performance reactivation technology with Fullers Earth installed in the plant for two to three years. All gas emissions from the burning of the contaminated Fullers Earth pass through Activated Charcoal prior to any remaining VOC’s and other pollutants being burnt off in the Catalytic Convertor before being released to the atmosphere.

Specialist services for transformers

Transformers are able to keep operating because of the paper that provides the mechanical strength to hold them together. This paper not only provides mechanical strength but dielectric strength and dielectric spacing too, enabling the transformer to withstand mechanical vibration, switching surges, line surges and limited short circuits.

However, as the transformer ages the paper insulation loses this ability. To try to minimise this, the transformer also contains mineral oil to provide the paper insulation with protection, in the form of dielectric strength and cooling. Because this oil is an organic compound it also degrades and oxides, reducing its effectiveness and protective abilities. And that’s where we come in.

Mobile transformer oil processing plant

As the sector leader, we at Utility Oils continue to innovate to provide a better and more cost-effective service for our clients. One of the latest innovations we have recently introduced is our mobile transformer oil processing plant.

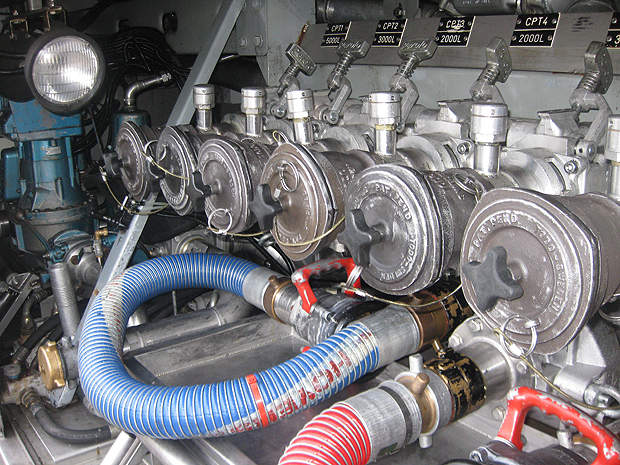

Our mobile transformer oil reprocessing plant is a rigid vehicle box van with the following features:

- Dual filter facility with various micron ratings down to 0.2µ

- Dual strainer facility

- Variable flow rate of between 2,000l/hr and 10,000l/hr

- Two-stage vacuum facility offering a 200m³/hr vacuum pump and a 1,400m³/hr vacuum booster with a vacuum connection point to allow the same vacuum facility to be used to pull vacuum within a transformer

- Heating facility in four stages, offering a total of 160kW

- ln-line moisture meter to detect moisture from source prior to transformer

- Fully automatic with air-operated valves; full interlock will close valves automatically

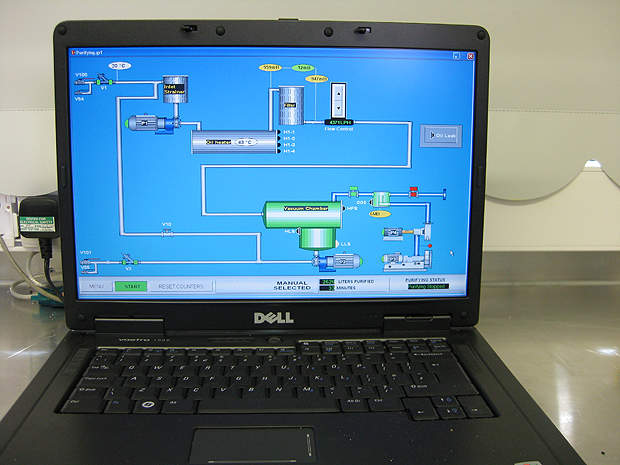

- PLC control via laptop facility

The plant will be capable of reducing in single pass content from 50ppm to 3ppm moisture and 12% gas content to less than 0.1% by volume. 98% of particulate matter will also be removed. All oil will be processed to a minimum of BS:148 or any other customer specification.

Road tankers

We provide the following range of road tankers and services:

- Road tankers ranging from 28,000l single-compartment to single-axle urban artics; all our tanks are fitted with bulk cargo pumps

- Supply new insulating oil and dispose of used; Customs & Excise tide oil dealer

- Large multi-compartment tanks (three, four, six and seven) with one or two pumps with compartment capacities ranging from 1,500l to 12,000l

- Twin axle (one steering) medium-sized urban distribution tankers with seven compartments, with compartment capacities ranging from 2,000l to 12,000l; tankers all have two pumps, reels and mechanical ticket printers

- Single-axle rear-steer small urban distribution tanks with six compartments, capacities ranging from 1,500l to 5,000l per compartment; vehicles also have two pumps, reels and electronic ticket printers