S.T. Cotter Turbine Services (S.T. CTS) is a privately owned rotating machinery field service company. Our field personnel have extensive safety training and experience on a wide range of projects. Supporting the field personnel is a team with 75 years of project management experience from around the globe.

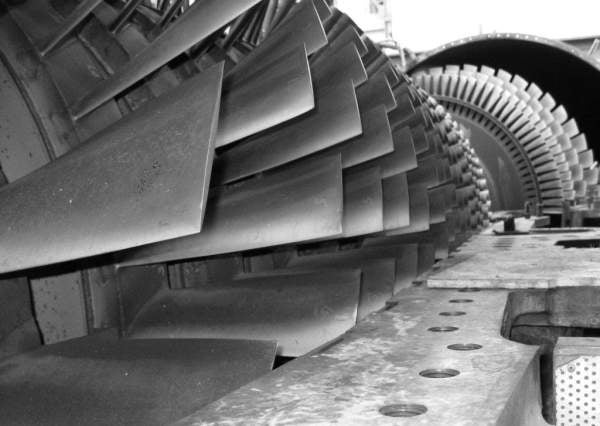

Parts, repair and field services for steam turbines

Our supervisors have experience on both fossil and nuclear steam turbines, from six-stage fan and chiller drive turbines to 1,100MW generation units. Some of the services we provide for steam turbines include:

- Parts

- Repair

- NDE

- Grit blasting

- Boresonics

- Technical direction

- Rewinds and rewedges of generators

Inspection, refurbishment and field services for gas turbines

In addition, our team has experience with gas turbines manufactured by both domestic and European manufactures. Services we provide for gas turbines include:

- Combustion inspections

- Hot gas path inspections

- Major inspections

- Generator inspections

- Parts refurbishment

- Parts procurement

Refinery and chemical services

Our extensive rotating machinery background does not end with the power block; we have craft and technical direction that performs daily maintenance as well as turnaround planning and execution. We have the engineering talent to preplan, supervise, support with safety professionals, support all craft, and provide repairs and parts for most refinery equipment.

- Elliott and Dresser drive turbines

- York/Conhagen compressors

- Elliott barrel compressors

- Carver boiler feed pumps

- MAN diesels

- Gear boxes

- Compressors

- Drive turbines

- Chiller turbines

- Fin fans

- Barrel compressors

- Horizontal plunger pumps

Maintenance services for rotating machinery

Rotating machinery is another of S.T. CTS’s specialties; we have experience in rotating and reciprocating machines of all makes and models. We also perform in-house maintenance and offer predictive and preventative maintenance services for equipment such as compressors, drive turbines, chiller turbines, fin fans, barrel compressors, and horizontal plunger pumps.

Turnkey generator services

As a complete turnkey service provider we understand that customers demand a complete solution. In addition to technical direction, labor and turbine repairs, we also offer a full line of generator services, including electrical testing, exciter repairs, stator repairs, and rotor inspections and repairs.

Borescope and boresonic inspection services

The ability to perform a borescope inspection to look for a lost item or as part of a minor inspection on a gas or steam turbine can be an integral part of an FME program. We have the ability to view record and report our findings so you can review the objects at a later time either on paper or electronically. We can perform the following inspections:

- Combustion turbine inspections

- Steam turbine minor inspections

- Generator inspections

- Pipe and extraction line inspections

- FME inspections

- Boresonic inspections

Balance of plant (BOP) services

As a full-service millwright operation, our craft labor is also able to assist in the additional services listed below:

- Auxiliary turbines and valves

- Pump inspection and alignment

- Pump installation

- Coal mill inspection and maintenance

- Conveyor systems maintenance and installation

- General maintenance