Pilgrim Shows Emergency Reactability by Mobilising Service Team in 24h

Connah’s Quay Power Station is a 1,420 MW gas-fired power station in Flintshire in North Wales. The current station is built on the site of a coal-fired power station. The old station was opened on 16 September 1954 by Lord Citrine, the chairman of the British Electricity Authority.

In 2018, during an inspection, UNIPER could not turn the HP-IP/GT shaft so it called Pilgrim to assist with the removal of previously supplied Radial Fit Bolts that were difficult to access because of the position of the pedestal. Within 24h, members of the Pilgrim’s Service team were on site and provided UNIPER with a safe and efficient removal process. UNIPER also requested that Pilgrim make a proposal for a permanent solution that could be used in restricted access areas.

Solution

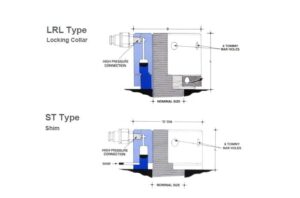

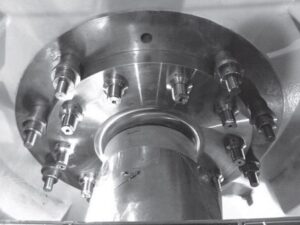

Dual Bolt Tensioning Kit specifically designed to accommodate restricted space was fitted, allowing UNIPER the ability to removal all Radial Fit Bolts regardless of the shaft orientation. The kit consisted of a puller, hydraulic head, removal bridge, tensioning bridge, adjustable setting bridge, nut rotating ring, and oil injection adaptor.

Benefits:

- 24h response to the initial request for assistance.

- Bespoke design that can be used in all situations.

Customer testimonial

Connah’s Quay Steam Turbine Engineer Jeff Hughes said: “As a single shaft Combined Cycle Gas Turbine Power Station, all shaft-line couplings were upgraded over a period of five years to Pilgrim fasteners. These fasteners have performed consistently since their installation and return each coupling to a concentric condition with minimal effort. During a recent inspection, emergent works necessitated the split of two couplings for further investigation. Unfortunately, it was not possible to turn the shaft and access to one of the couplings is restricted due to the design of the pedestal. Our site team made contact with Pilgrim International Ltd and a small team was rapidly mobilised to assist with the removal of the coupling bolts. The technical support provided was excellent, and over the course of a day, fasteners were removed and the investigation allowed to progress. Whilst onsite the team took dimensions to enable the design additional tooling to be utilised in the event of a future issue. Excellent service and technical support has been provided from the first installation.”