Pilgrim International offers bolting and positioning systems, hydraulic bolt tensioning solutions, drive-up systems and hydraulic pump packs specifically designed for the power industry.

With extensive experience as a technical partner to equipment manufacturers and end-users in the power industry, our high-integrity fastening systems aim to increase safety. We provide solutions for stuck bolts, accurate and repeatable bolting or effective tightening of steam or gas turbine casings.

Pilgrim is an expert in high-pressure hydraulic solutions and exotic material machining with documented traceability.

We also serve a number of sectors, including energy, marine, oil and gas, civil engineering, industrial, mining, aerospace, construction, bulk handling, defence and transport.

Bolting and positioning systems for the power industry

Pilgrim offers high-integrity reusable and easy-to-install bolting solutions for coupling re-machining and replacement bolts.

The method of installation, material, clearance and the possibility of vibration can cause stuck bolts during the installation or removal process and is regularly witnessed in high-speed coupling applications typically found on power plants.

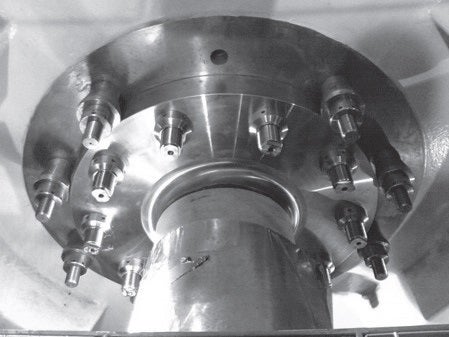

Pilgrim Radial Fit Bolts have tapered sleeves that expand to fill the bolt-hole space. The hydraulic system applies tension and creates a truly fitted bolt. The lightweight air-driven bolts use hydraulic equipment for tensioning and separating or disassembly.

With a clamp bolt, the system relies on friction only to drive torque requirements. Radial Fit Bolt transmits torque through the body of the bolt, using the strength of the fastener and the friction force created by the axial load.

Radial Fit Bolt is a direct retrofit solution that prepares the coupling hole the same way that standard bolts do. The key advantage of the Radial Fit Bolts is that the hole preparation is not required on subsequent coupling splits.

The sleeve outside diameter of the Radial Fit Bolt is supplied oversized to allow for final machining or honing at the site once alignment and coupling concentricity checks have been conducted.

Tensioning systems for the power industry

Pilgrim’s HYDROCAM® hydraulic bolt tensioners can axially stretch a bolt or a stud to create a high-integrity fixing, which can be coupled and de-coupled when required.

High integrity means a known performance normally measured in retained residual load, ensuring the design of the connection, is in line with the predetermined performance requirements.

HYDROCAM® hydraulic tensioners can be operated as a single tool or, if required, incorporated into a multi-tensioner for homogeneous tightening of turbine casing or cover. We also offer a range of high-temperature hydraulic nuts.

Drive-up systems for power sector applications

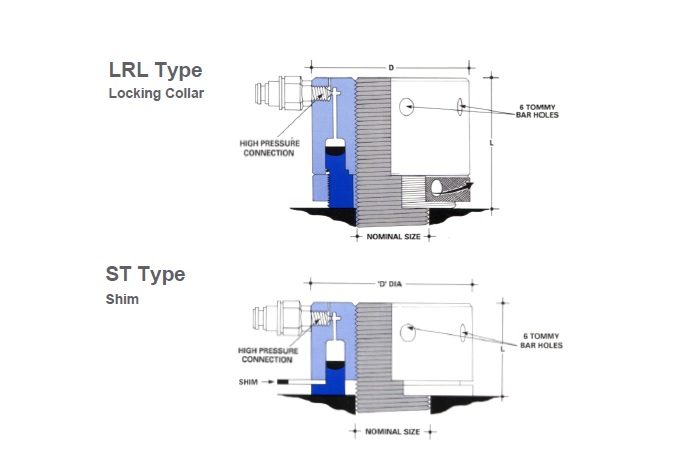

Pilgrim’s range of hydraulic nuts and jacks offer an optimal solution for drive-up systems.

We can provide a system if you need to locate a roller bearing up a tapered journal. You can also choose from our range of hydraulic jacks to use in confined spaces.

Featuring a high-pressure sealing system, Pilgrim’s Ringjack hydraulic nut facilitates a smooth assembly. The compact Ringjack design is suitable for mounting onto the bearing journal to provide axial movements for final positioning.

Training, supervision and installation services for the power industry

Pilgrim offers additional services such as maintenance training, site supervision and installation, on-site machining, spare parts, training kits, refurbishment, and design studies that include finite element analysis (FEA) and support documentation.

Hydraulic and air-powered pumps

To enable quick and safe installation and removal of our products, Pilgrim provides a range of high-quality hydraulic power packs, including air and electric-operated hydraulic pumps, as well as piping and hydraulic fittings that are designed to be used in a power plant.

About Pilgrim

With more than 80 years of specialist experience and a team of experts, Pilgrim provides innovative high-quality engineering products and services worldwide.