Incoil Induktion supplies induction solutions to companies around the world. Induction heating systems are used in a range of industries, including the power generation industry. Some applications that are well suited for induction are:

- Soldering and brazing

- Hardening

- Hot forming

- Straightening

- Forging

- Shrink fitting

- Melting

- Annealing

- Adhesive curing

Mobile induction units

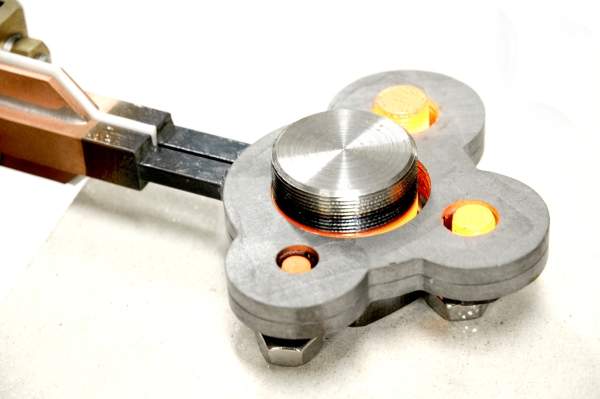

The flexibility of Incoil Induktion’s IH series induction heaters enables improvement of the efficiency of a number of industrial applications. The unit features a clever bayonet joint which allows the easy exchange of induction coil/tool depending on the item that needs to be heated.

This compact and mobile induction heating unit is available in a range of outputs between 3.5kVA and 44kVA.

The conversion efficiency is very high due to induction and the tool’s unique design; every induction coil is optimised according to what you need to heat. Wherever you need to heat up metal, induction is the way to do it; it is a flameless heating which allows you to heat where you can’t use an open flame.

Induction heater advantages

Mobile induction heaters from Incoil Induktion are cost-effective, user-friendly and safe. They are low weight and high performance, and use advanced, modern technology to perform rapid and efficient heating.

Induction coils for bolt expansion

Incoil Induktion uses specially designed coils to expand bolts on power plants. This method has proved to be a real time saver. Instead of using flame or resistance heating we use our induction coils.

Handheld transformers (HHT)

With all of our machines you can either hold the transformer in your hand using a specially designed handle with a potentiometer for step-less power regulation, or you can implement the transformer in a soldering station – the possibilities are endless.

Induction coil designs

Every customer has different requests regarding what to heat; our machines are built so that they adapt to the coil, which allows a big variety of coil designs.