HYDRO Exploitation is a specialist service provider in operations of electrical installations and hydroelectric facilities. We provide all services for operation, maintenance and overhaul.

Based in Sion, Switzerland, we operate facilities that produce nearly 16% of Switzerland’s total of hydroelectric output.

Risk analysis at hydroelectic facilities

Our risk analysis service identifies security risks that might cause a total or partial malfunction of a facility; it also evaluates environmental and operational risks. The analysis of risks is based on the case history of operations and maintenance undertaken. It is carried out in collaboration with those responsible at the power plant, in addition to civil and computer engineers.

Serviceability of hydropower plants

Serviceability is a quantitative technical analysis based on international standards. It enables owners of hydroelectric facilities to estimate the residual life of their equipment, any renewal works and maintenance needed, as well as the regularity.

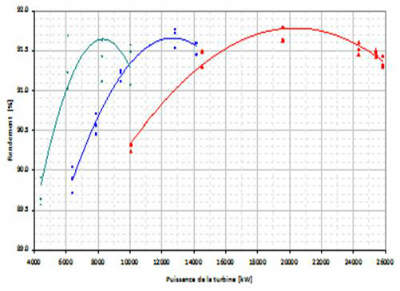

Thermodynamic efficiency measurement

The performance of hydroelectric units must be checked at regular intervals to ensure sufficient machine output. HYDRO Exploitation ensures the quantitative and qualitative measurement of these units.

It is then possible to determine how performance levels can be maintained after reconditioning or validate the warranties given by the wheel supplier

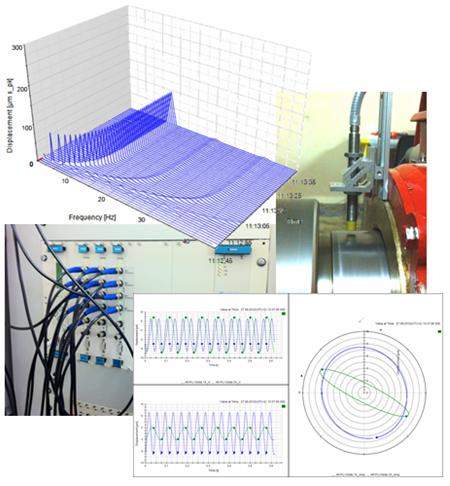

Vibration diagnostics of hydroelectic machinery

Vibration monitoring of hydroelectric units is an essential safety factor for ensuring that they are operating correctly.

HYDRO Exploitation SA monitors the quantity and quality of the vibrations of machines. This makes it possible to determine changes in the vibratory behaviour of a unit during its lifecycle between two reconditioning operations and ensures early detection of any difference in behaviour.

The customer is provided with a detailed vibration diagnosis of the machine’s condition, i.e. machine balancing and alignment problems.

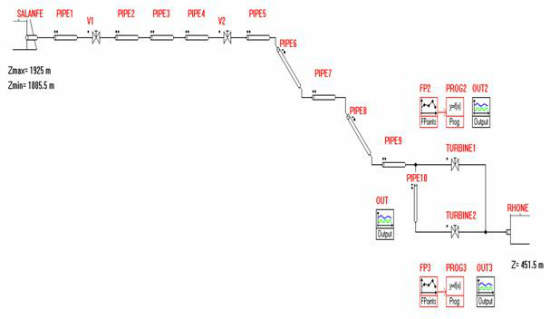

Risk identification modelling and simulation software

To ensure the safety of hydroelectric facilities, HYDRO Exploitation has developed a proactive, systematic method of identifying, assessing and managing operational risks. Hydraulic and electrical modelling, simulation and the turbine control system of hydroelectric facilities are controlled by SIMSEN software.

Precise laser measuring of hydroelectic machinery and equipment

Our Laser Tracker measures in three dimensions; due to its technical characteristics, it meets the high requirements for measuring the size of mechanical objects even as small as a few hundredths of a millimetre.

These measurements are used for monitoring hydroelectric generating units, aligning machines or tracking the movements of civil engineering structures. Laser Tracker is used in many industries, including aerospace, machinery and shipbuilding.

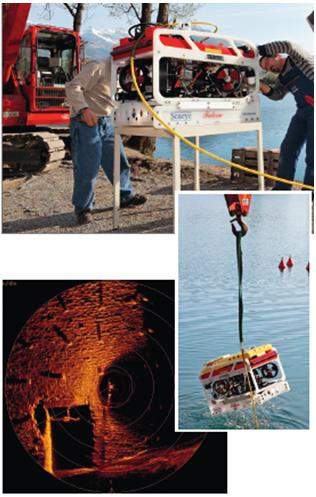

Underwater inspection services

Underwater inspection enables owners to determine the condition of their hydroelectric facilities, such as concrete structure and mechanical elements, by overcoming constraints in both depth and visibility.

Sediment analysis

Solid material (SM) transported by water collected for hydroelectricity production has a negative impact on the operations of these facilities. In catchment areas, retreating glaciers have exposed new zones of erosion, which have contributed to an increase in the quantity of transported SM.

When faced with this problem, it is necessary to have a complete understanding of the particular parameters of each facility in order to take appropriate measures for conserving storage volumes and minimising wear on mechanical parts.

Through our global approach and integration of the various factors influencing the transport of solid material, our sediment management range of made-to-measure solutions guarantees long-term functionality of equipment.

Eliminating sediment build-up with pumping

Over time, sediment accumulates in water storage points such as as dykes, dams, intakes, deep sluice gates and main sluices; this can cause a decrease in reservoir volumes. Such problems force operators to evacuate sediment on a regular basis, as leaving it can result in significant disruptions to operations.

HYDRO Exploitation proposes thorough sediment management services, with all the necessary pumping equipment.

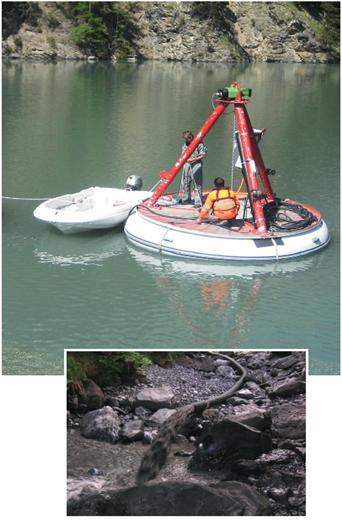

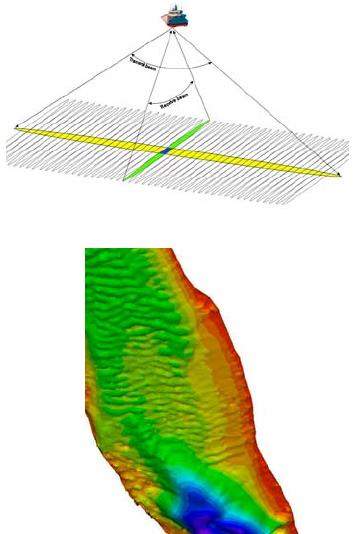

Multi-beam bathymetry

Knowledge of the morphology and volumes available in hydroelectric station reservoirs is essential for optimal management of production. Bathymetry reports reproduce the topography of lakes efficiently without causing any loss of water. This provide owners with the present level of silting and the volume of available storage.

This also offers the opportunity of following the evolution of silting up of dams, contributing to improved scheduling of maintenance operations and ensuring permanence of the layout with silting.

Multi-beam technology opens up new perspectives of bathymetric readings. The process enables highly decisive readings to be taken from the bottom of the reservoir at high-speed. The quality and accuracy of the measures are greatly improved compared with those taken using older instruments, which means that the smallest structures can be viewed even at great depths.

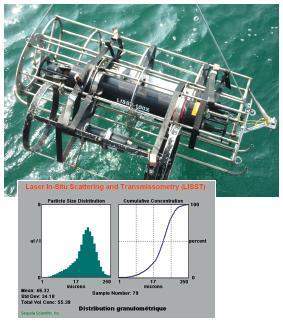

Sediment monitoring

The physical characteristics of transported material in suspension (MES) and its concentration dictate the sedimentation mode of basins and speed of turbine abrasion.

To assist the latest technology in material analysis, the MES present in water, its concentration and grading can be analysed continuously. The spatial distribution of speeds and MES in a complete section can be known by using acoustic doppler measures (ADCP).

Monitoring these observations enables the sedimentary spate to be characterised and, depending on circumstances, wear and tear of machines from abrasion is minimised, silting of dams is limited and dilution regulations are met.