Hibbard Inshore is an underwater inspection and construction services company with over 27 years of experience in providing inspection and construction support for structures associated with power generation at coal, nuclear and hydroelectric generating facilities.

These structures are inspected using the Hibbard Inshore fleet of remotely operated vehicles (ROVs), including swimming vehicles for fully flooded areas, crawling vehicles for dewatered or mostly dewatered situations, and floating vehicles when inspection calls for assessment both above and below the water simultaneously.

Video and sonar structure inspection

Managing and maintaining the condition of critical structures and assets for functionality, lifespan, and regulatory compliance are common challenges for facilities. Hibbard Inshore helps its customers address these challenges by giving them quantifiable data on the underwater portions of their structures, allowing them to plan and perform necessary maintenance proactively.

Structures Hibbard Inshore can inspect include: trash racks, discharges/lower outlets, face of dam, intakes, head gates and seals, stoplogs, reservoir bathymetery, toe of dam, toe drains, penstocks (flooded and dry), turbines, turbine shut-off valves, diversion tunnels, and long conveyance tunnels. These inspections can be completed without dewatering and can often be completed while adjacent units or spillways are still running, decreasing the overall inspection impact on facility operations.

Dredging and debris removal in front of intakes

If intakes are blocked, facilities are not able to generate at full capacity. Removal of this debris can often be time-consuming and dangerous for dive crews especially if the intakes are in deep water or flow is present. Hibbard Inshore helps owners address this issue by using its fleet of ROVs to perform debris removal and dredging in front of generating units.

Hibbard Inshore’s method allows for dredging and debris removal to take place using unmanned equipment. Because this method does not require people to be in the water, many times the work can be performed while adjacent units are still in operation. Additionally, this work can be performed in low or zero visibility conditions continually and effectively. The ROV is used to direct the underwater removal process as well as to measure the progress. Additionally, the ROV dredging and debris removal solution has unlimited bottom time helping the job to completion quickly and efficiently.

Deep water bulkheading

Valves often need to be replaced or installed in an existing line for added functionality. These replacements can often be accomplished without dewatering through the installation of a temporary bulkhead. In cases where there is high head pressure or the bulkhead needs to be positioned after a long excursion through a tunnel, both reservoir dewatering and saturation or deep, mixed gas diving can be costly. In the case of dewatering, there are also a potential for fishery, recreational, or other undesirable impacts such as structural strain.

Hibbard Inshore is able to address this problem using ROV placed and actuated bulkheads. The ROVs take accurate dimensioning of the structure in need of bulkheading, and engineers design and fabricate the bulkhead to need. Then, the bulkhead is placed with unmanned vehicles and rigging, seals are actuated, and the bulkhead is monitored for safety of man access.

Long tunnel inspection

One issue that many facilities face during their lifespan is the need to conduct a condition assessment on long tunnels. These tunnels are critical to the proper operation of each facility and can cause extreme issues should they encounter a failure or blockage situation. Because it is often impractical or very costly to dewater the facility to inspect these tunnels, they can provide distinct challenges to conducting a thorough inspection while minimizing outage times.

Hibbard Inshore is able to address these situations in fully flooded tunnels with a comprehensive fleet of underwater vehicles and sensors. Hibbard Inshore’s vehicles are capable of providing real-time video and inspection sensor data at ranges exceeding 20km. Also, in many cases, the vehicles are able to conduct inspection tasks in light flow situations at great distances. This allows plants to maintain necessary minimum or environmental flows during the inspection process.

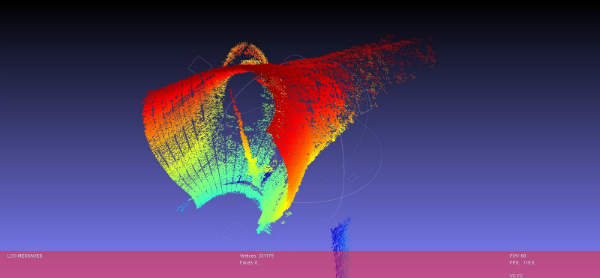

In addition to inspection of fully flooded tunnels, Hibbard Inshore also can provide 3D laser and video inspections of large diameter, dry tunnels up to 3.2km in length. If your facility has a dewatered tunnel that may not be safe for a walkthrough inspection, Hibbard Inshore can provide a robotic solution to get you the data you need while keeping your staff and contractors safe.

If your facility has a long-range tunnel that is in need of condition assessment, we would be happy to help you to form a plan to get the data needed to make critical lifecycle decisions with respect to your facility.