For decades EFD Induction has been bringing the benefits of induction heating to companies in the global power generation and distribution industries. The flexibility of EFD Induction systems lets them be used for practically any application in the power industry that requires heat. We also custom-make coils to suit specific applications and geometries.

The induction heating systems developed by EFD Induction are used primarily for the following tasks within the power industry:

- Brazing series connections

- Brazing turbo-generator connections

- Brazing short-circuit rings

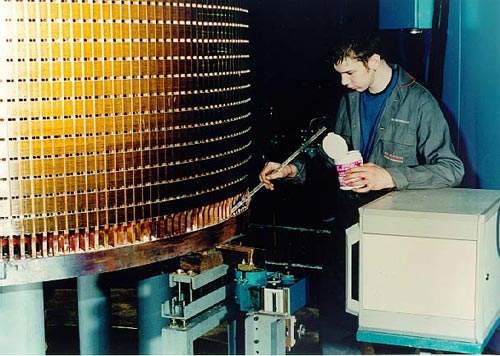

- Solidifying bar ends

- Brazing strands / windings

- Shrink-fitting of end caps

- Cleaning varnish

- Post and pre-heating

- General shrink-fitting

- Expanding and removing of large bolts

Fast, safe and reliable induction heating systems

The key benefits of EFD Induction systems are speed, safety and reliability. When brazing series connections, for example, our induction systems’ precise heat pattern, rapid heating and narrow heat range virtually eliminate the risk of burn damage to the insulation.

Induction heating systems also minimise preparation work. This is particularly relevant when compared with flame brazing, where considerable time must be spent on protecting the insulation.

Handheld transformer for induction heating systems

EFD Induction provides a range of innovations and optional functions that further enhance productivity. For instance, we have developed a handheld transformer that incorporates a clamping mechanism. This eliminates the need for a separate clamping operation when brazing strands and wires, or when solidifying bar-ends.

Single-turn induction heating systems

We specialise in using single-turn inductors (coils) when brazing smaller-dimensioned work pieces. These coils minimise losses, which in turn reduces energy consumption.

Mobile and compact induction heating systems

The EFD Induction Minac range of mobile and compact induction heating systems is widely used by service and maintenance companies.

The small footprint, ease-of-use and manoeuvrability of a Minac make it ideal for power industry environments. A Minac is flexible, too: it is capable of performing heating tasks as diverse as brazing, pre and post-heating, shrink fitting and removing, and varnish removal. A single Minac converter supports a virtually unlimited range of custom-built coils.

Many Minac induction heating systems come in twin versions offering two independent power outputs (in effect doubling the productivity of a single system). The twin versions feature split-control panels from which each output can be controlled.

Minac induction heating systems can also be used together with separate heating stations. This lets the Minac support large, flexible coils that can be shaped on-site to fit curved or irregular-shaped work pieces.

Fast and reliable bolt-expansion system

EFD Induction’s bolt-expansion system is the proven time and labour-saving alternative to inefficient flame and resistance heating. With induction, a coil is inserted into the bolt. Controllable and localised heat is then induced directly in the bolt. The heat expands the bolt by an exact, pre-decided length, making it easy to remove the nut.

The speed and precision of induction heating prevents damage to the threads. The process is so quick there isn’t enough time for heat to travel into the thread area, and there’s no risk of rods melting inside the bolt (a common drawback with alternative heating methods).

With induction, crucial process parameters such as temperatures and dwell times are set in advance. Productivity is boosted by quick-release coils. It takes only seconds to attach new coils to the handheld transformers. The coils can be used with angle adapters to ensure smooth passage of the coil into the bolt.

EFD Induction bolt expansion systems use mobile Minac converters and elongated coils. When using a Minac Twin, one operator can work on two bolts at the same time — in effect achieving the productivity of two operators. Alternatively, two operators can work simultaneously, each with their own independent handheld transformer.