D-velop Engineering cooperates with a partner to offer inspection equipment and inspection services for both steel and composite materials within the electrical power industry. Our innovative equipment enables us to detect wrinkles in the distribution of fibres in composites – a unique feature of our service.

Together with our partner we are highly specialised in ultrasonic inspection for the wind turbine industry. Our product range covers scanners for quality control during production of wind turbine blades and towers, hydro plant turbines, etc. In addition, we offer services for on-site inspection of installed equipment, even subsea.

Automated ultrasonic inspection equipment and services

We supply automated ultrasonic inspection equipment and short-term or long-term ultrasonic inspection services for inspection, on-line control and optimisation. Our advanced automated ultrasound equipment is ideal for the inspection of multi-layer composites and metals, to detect corrosion, delamination, porosity, cracks and other defects.

Our ultrasonic inspection equipment is used in many industrial applications such as inspection of:

- Heat exchangers

- Wind turbine blades and towers

- Pressurised vessels

- Nuclear reactors

- Steel and concrete structures

Automated weld inspection

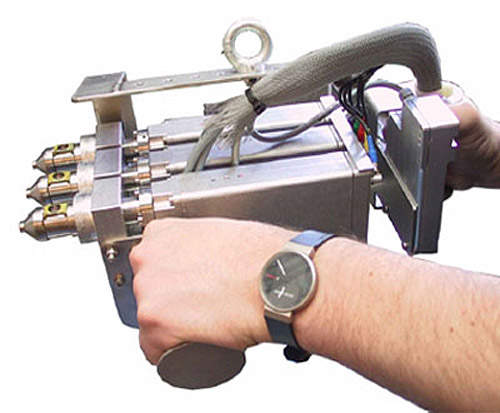

We offer a wide selection of scanners for a variety of inspection applications, including:

- Automated weld inspection in heat exchangers

- Automatic inspection on steel

- Steel and weld quality inspection

- Ultrasonic inspection of complex shaped welds

The scanners are based on modules that can be combined in innumerable combinations and can cover almost any surface and scan path. We can also provide customised scanners for tasks where the surface or path is too complex for the use of module-based scanners.

Wind turbine rotor blade inspection

The advanced composites used in wind turbine rotor blades are layered structures. Typical defects are delaminations, adhesive defects and resin-poor areas. Ultrasonic inspection reveals these flaws quickly, reliably and effectively.

We offer automated systems for scanning, detection and registration of thickness, delamination, dry area, gelcoat disbond, porosity, kissing bond and missing adhesive.

Our systems can even detect waves and wrinkles in the distribution of the fibre mats.

Wind turbine blade UT inspection

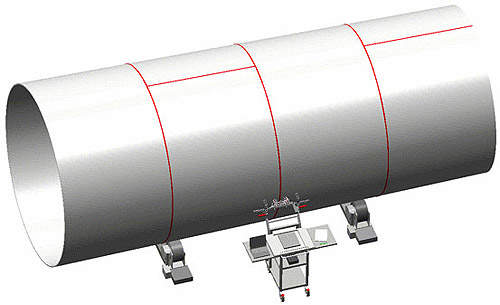

We supply automated ultrasonic inspection equipment and services specially designed for the wind turbine industry.

Our ultrasonic testing (UT) equipment is designed for the inspection of wind turbine blades and towers. We provide inspection services and inspection equipment for regular control during production or for on-site inspection, to discover repetitive production errors and avoid hazardous break down of installed blades and towers.

Wind turbine blade NDT inspection

The increasing use of plastics and polymer-based composites in industrial structures has led to a growing need for methods that can reveal hidden flaws and defects in these materials. Using non-destructive testing (NDT) methods to inspect wind turbine blades made of composites provides several benefits:

- Serious production flaws can be discovered in time

- Reduced failure rates result in less wasted material, lower repair costs and therefore increased productivity and efficiency

- A high and uniform product quality can be achieved

- A reliable determination of the extent of damage can be made before repairs

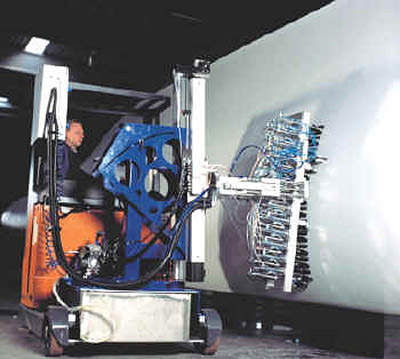

Wind turbine tower scanners

We offer automatic ultrasound scanners for inspection and registration of longitudinal, circumferential and flange welds on wind turbine towers and similar constructions.

The UT scanner can be handled by one operator, is easy to calibrate and uses water as coupling agent. It provides users with a highly reliable inspection system for fast and efficient control of flange and butt welds in the production of steel towers.