Burmeister & Wain Scandinavian Contractor (BWSC) is a leading provider and operator of customised diesel, combined cycle and biomass power plants.

Investment, design and construction of power plants

BWSC offers its customers a range of services, including:

- Development, financial engineering and investment in power plants

- Plant design, engineering, procurement and construction (EPC)

- Operation and maintenance (O&M)

- Parts, service and rehabilitation

- Plant staff training

- Comprehensive operation and maintenance support agreements

BWSC has experience and in-depth knowledge accumulated from designing and building more than 175 power plants, as well as operating and maintaining more than 3500 MW of base-load generation equipment worldwide.

BWSC understands the requirements of power plants in all parts of the world, whether fuelled by diesel, straw or wood and whether afloat or land-based, irrespectively of engine or boiler manufacturer.

It is the company’s mission to secure reliable and efficient operation of its customers’ plants. BWSC handles large and medium-scale power plants, combined heat-and-power (CHP) plants, and renewable energy power plants running on biomass or biogas.

Local staff training and partners

At every site, BWSC partners with the local authorities and populations. The majority of BWSC employees are local, ensuring continuous service improvement in addition to local growth and prosperity.

The company aims to build on the local skills and expertise. Accordingly, it organises a variety of training programmes and is involved in the local schools, as the children often grow up to become part of the future workforce.

BWSC relies on its experienced employees as a key asset and empowers them with full responsibility to take action to solve any issues on the spot.

24-hour power plant protection

Successfully operating a power plant is a 24/7 task. As a plant owner or investor, customers anticipate and expect smooth, continuous operation with high levels of availability and reliability.

BSWC stands for round-the-clock safeguarding of power plants to protect customers’ investments.

Regardless of the amount of preparation, issues will inevitably arise, in which cases it is imperative to be able to rely on experienced, qualified and dedicated staff to be on the spot to find a speedy solution.

EPC and O&M in challenging conditions

BWSC naturally fulfils contracts and agreements, delivering on time, on budget and at the specified performance level.

The company assesses problems directly to find and implement the right solution, and its reputation for fast and reliable technical solutions is well-established in the industry.

Working in difficult, remote and challenging environments is customary to BWSC. The company relies on cooperation and teamwork with its main equipment suppliers, local service providers and customers to achieve results.

BWSC invests in and co-owns a number of the plants which it builds and operates.

Health and safety

Health and safety is BWSC’s top priority, and highly skilled staff members ensure that BWSC meets high safety priorities and standards. As a result, the company’s safety records are excellent.

O&M plants are run by teams with an intimate knowledge of the plants and, therefore, acute awareness of any potential risks.

Selected operation and maintenance projects

BWSC has constructed more than 175 power plants. Power plants where BWSC currently has the operation and maintenance contract include, but are not limited to:

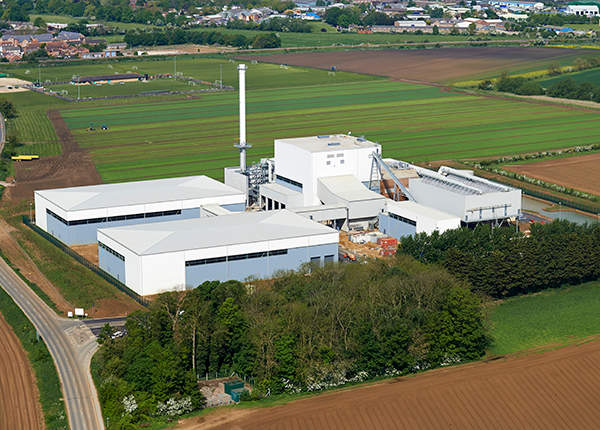

- Brigg, UK. 40 MW straw. 15 years (2016-2031)

- Cramlington, UK. 28 MW virgin wood. 12 years (2018-2030)

- Lisahally, Northern Ireland. 16 MW waste wood. 15 years (2015-2030)

- Rabai, Kenya. 90 MW diesel. 20 years (2009-2029)

- Sleaford, UK. 39 MW straw. 12 years (2014-2026)

- Snetterton, UK. 44 MW straw. 15 years (2017-2032)

- Speyside, Scotland. 12 MW virgin wood. 12 years (2016-2028)

- Tilbury, UK. 40 MW waste wood. 20 years (2017-2037)

- Widnes, UK. 20 MW waste wood. 20 years (2016-2036)