American Polywater® Corporation is a leading manufacturer of cable pulling lubricants, cleaners, sealants and MRO and construction chemicals used in the installation, maintenance and protection of power infrastructure assets.

Installation, maintenance and barrier technologies for effective power asset installation and protection

Polywater® supplies a wide range of products that reduce the costs of installation, maintenance and protection of infrastructure assets, including underground cable systems, cable duct and raceway networks, as well as electrical transformers / switchgear and their protective enclosures.

The company’s cable pulling lubricants are used to reduce tension and sidewall pressure on power cables when they are deployed into raceways. In addition, environmental protective barriers and repair technologies are used to stop the ingress of water, gases and animals to prevent damage to valuable assets. They also prevent the loss of oils and gases from transformer oil or SF6 switchgear leaks.

Polywater® cable prep, MRO and live-line cleaners are used in the preparation of the cable prior to splicing or termination, and to clean and treat protective equipment such as hot-sticks, insulated rubber goods and telescopic booms.

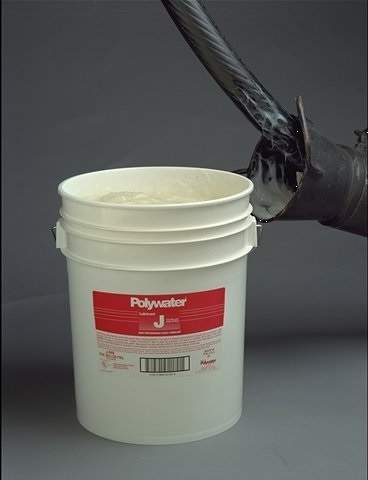

Cable lubricants for electrical cable installation

Polywater’s lubricants produce the lowest coefficients of friction (COF) in the power market and are compatible with common raceway and cable jacket materials, including PVC, PE, XLPE and low-smoke zero halogen. Water-based cable pulling lubricants are used for electrical cable installation in ducts and raceways.

Polywater® cable pulling lubricants are used in nuclear, thermal and alternative energy plant construction, as well as transmission and distribution cable networks. They set the worldwide standard for tension reduction lubricants in infrastructure development projects.

They protect against deterioration and do not change the dielectric properties of the materials they come into contact with. With no flash-point, Polywater® lubricant residues do not propagate flames or generate harmful smoke.

Cable lubricants for LSZH installations

Polywater’s LSZH jacket-compatible cable lubricant can be used in environments at risk of fire and provide high-performance friction reduction and compatibility with all cable materials, including LSZH jackets.

The company’s LZ Lubricant has been tested and endorsed by major international power cable manufacturers, and will not cause deterioration of LSZH jacketed cables. It also ensures the long-term integrity of electrical cable networks, transit systems and high-occupancy public structures.

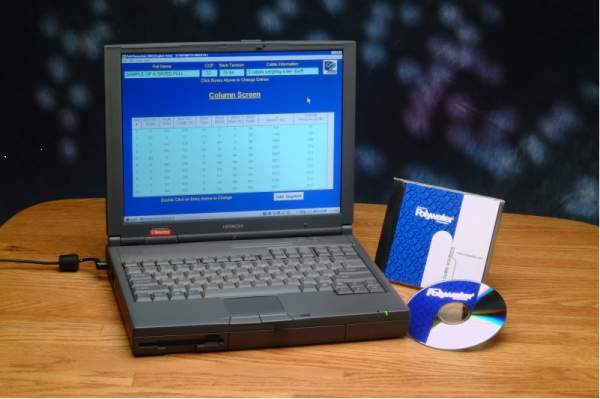

Tension and sidewall pressure software solutions

The PullPlanner™ 3000 cable tension and sidewall pressure estimation software optimises cable system design and performance. It allows infrastructure project developers to minimise project costs of their underground cable networks.

It uses data on the type of raceway and cable jacket materials, and the geometry of the raceway system to estimate the tension and sidewall pressures generated on the cable during installation.

Use of the PullPlanner™ 3000 software can help to reduce cable tension and improve overall power network integrity. It can also reduce the number of splices and hand-holds, and manpower costs.

Duct blocks to protect cable networks and equipment

Polywater’s FST™ Duct Block is a barrier technology for water pressure resistance, infrastructure asset protection and asset-hardening from water, gas and animal entry. It is a high-performance, closed-cell system that withstands water-head pressures of more than 5m and protects power cable networks and equipment.

Used in asset-hardening programmes to minimise power system asset damage from storm surges, flooding and animal infestations, FST™ minimises ongoing operating and maintenance costs of valuable infrastructure assets.

It is UL recognised as fire retardant and will self-extinguish once the flame is removed.

Transformer leak repair solutions

The PowerPatch® Transformer and Leak Repair system protects power infrastructure assets from operational faults and damage. It can be used on active transformer oil and/or SF6 leaks for permanent or temporary in-situ repairs.

Users can protect the environment and personnel by stopping leaks in the field without delays, at lower costs than traditional repair methods.

Cable prep cleaners for splicing and terminating power cables

Polywater’s SpliceMaster® cable prep cleaners are used for splicing and termination of medium/high voltage power cables to reduce faults and improve network performance.

These cleaners from Polywater® provide effective precision cleaning of medium / high-voltage cables before termination or splicing. The system leaves no residue and is compatible with all cable materials, including conductive and semi-conductive polymers. SpliceMaster® cleaners are environmentally safe and contain no class 1 ozone depletion components.