Weir Minerals are specialists in delivering and supporting slurry and de-watering equipment solutions including pumps, hydrocyclones, valves and wear-resistant linings for the global power, mining and mineral processing sectors, and general industry.

Focusing upon what we do best, Weir Minerals delivers on what matters to you most, bringing together an extensive global service and manufacturing presence combined with an investment capability able to develop, support and sustain market-leading technologies that deliver enhanced performance in your process-critical applications.

De-watering, process water and specialist slurry processing equipment

Through a customer-focused strategy Weir Minerals has used its unique technologies to develop an unrivalled range of mine de-watering, process water and specialist slurry processing equipment for some of your most critical processes. This means that today Weir Minerals is much more than a pump company.

Centrifugal slurry pumps, de-watering pumps, hydrocyclones, slurry valves, mill liners and elastomer wear products

Weir Minerals have pioneered and proven the technology and economics of transporting high-density residues and handling the highly abrasive and corrosive slurries in the flue gas desulphurisation (FGD) process and have many applications helping to solve the waste-handling problems in the nuclear power station environment.

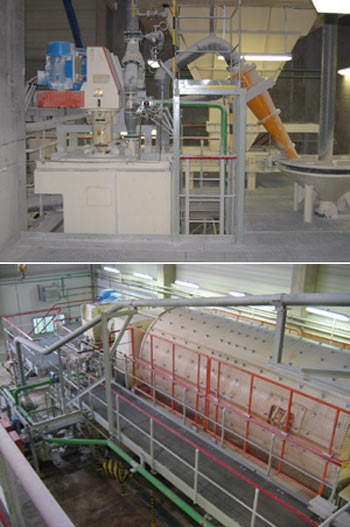

From ash disposal to absorber recycle, and sump clean up to SIXEP recirculation, the Warman centrifugal slurry pumps, Geho PD slurry pumps, Multiflo de-watering pumps, Cavex hydrocyclones, Isogate slurry valves, Vulco mill liners and elastomer wear products from Weir Minerals exceed customer expectations around the world.

Slurry and de-watering pumps for power plants

Just a few of the applications where you typically find Weir Minerals products in the power station environment are:

- Ash feed pumps

- Ash transport pumps

- Cyclone feed pumps

- High-density coal slurry pipeline pumps

- Gasifier slurry feed pumps

- PFBC boiler-paste feed pumps

- Limestone distribution pumps

- Absorber recycle pumps

- Gypsum recovery pumps

- Gypsum transfer pumps

- SIXEP recirculation

- Ash de-watering hydrocyclones

- Limestone-grinding circuit hydrocyclones

- Gypsum de-watering hydrocyclones

- Slurry pump isolation valves

- Slurry pipeline control valves

- Grinding circuit mill linings

Slurry transport and sloped-disposal technology

Historically, producing power has involved the burning of a fossil fuel, typically coal, to heat water and produce steam to drive turbines. However, this process produces a number of residues: fly ash, bottom ash and exhaust gases containing, among other substances, sulphur dioxide gas.

The fly ash and bottom ash generated are traditionally transported hydraulically or by mechanical means to ash dumps, requiring most power plants to operate their own lagoons. Hydraulic ash transport has largely been in the form of dilute slurries.

However, the protection of the natural environment has limited the number of available options and increased costs for disposal of solid residue from coal use.

Environmental problems are substantially eliminated by the dense-phase and high-density slurry transport and sloped-disposal technology Weir Minerals can provide. Also, growing environmental issues can be alleviated by the installation of FGD in power stations to remove the sulphur residues. This has historically been discharged directly to the atmosphere through the chimney stacks. However current legislation dictates that this must be ‘scrubbed’ and the sulphur residue removed to within certain levels.

Other methods of producing the heat required to generate electricity includes nuclear power, with its own waste product handling issues.