Wallace manufactures and designs more than 500 different portable gantry cranes for applications in the power industry.

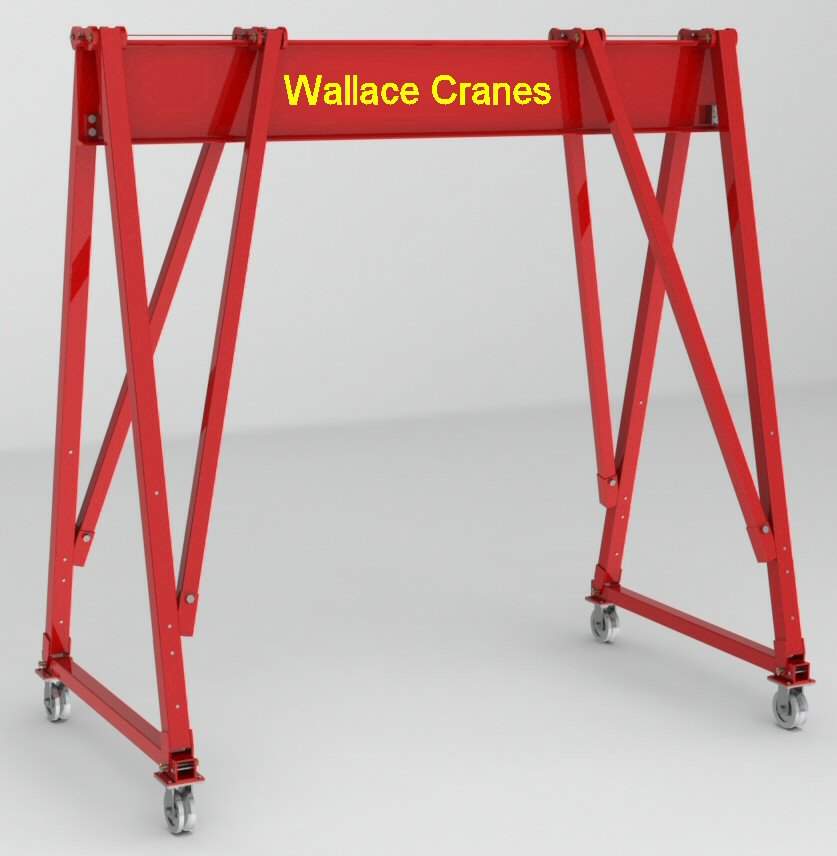

Portable gantry cranes

Models are available in steel, aluminum, and combination (steel frames with lightweight aluminum I-beams) along with a choice of adjustable or fixed heights. Wallace can provide cranes with capacties ranging from 1/4 to 15 tonnes, standard spans of 8ft to 35ft and heights of 5’3" to 24’0". Most cranes can be customised including fixed height models.

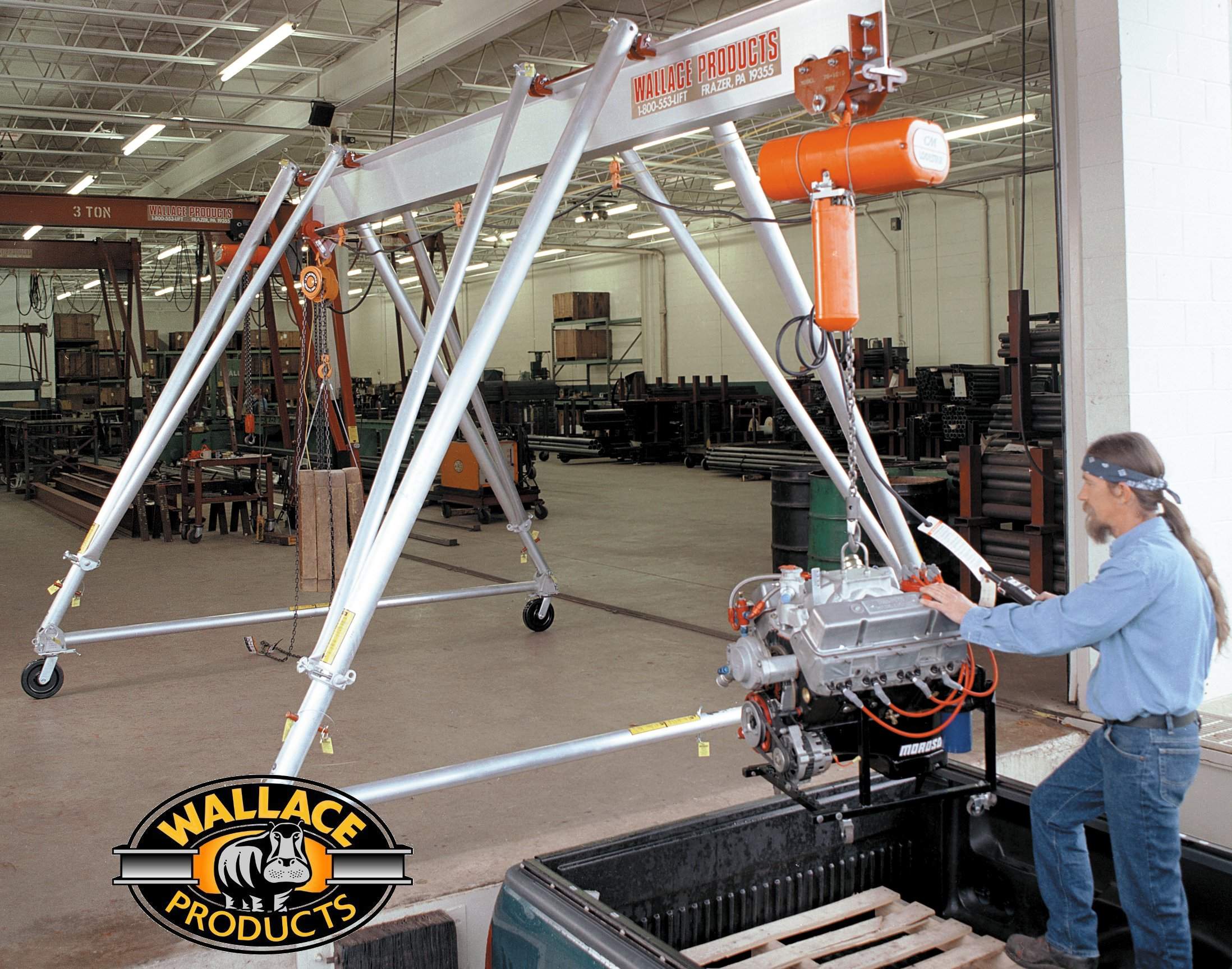

Hoists and trolleys, and movement of the crane itself may either be manual or powered. With low-friction casters, even the highest capacity manually operated versions can be pushed by hand. Expert staff from Wallace will help the customer select the right hoist and trolley for their crane.

Wallace cranes are built to conform to the applicable standards, such as ANSI B30.17 (Overhead Underslung Monorail), CMAA #74, OSHA 1910.179, AWS 14.1, and AISC for stresses. Wallaces’ high-quality products are found in many different applications throughout the power industry, including utilities (oil, gas, water, solar electric), nuclear power, heating, ventilation and air-conditioning (HVAC), cooling water treatment and commercial air compressor rooms.

Typical power utility applications include maintenance and repair and equipment installation. Wallace equipment can transport motors, pumps, gear boxes, valves, filters, and roof-mounted panels.

Another application is the installation of reduction gears and couplings between turbines and gear trains. The portable cranes can move easily on crowded shop floors and be assembled in place, spanning the equipment under repair.

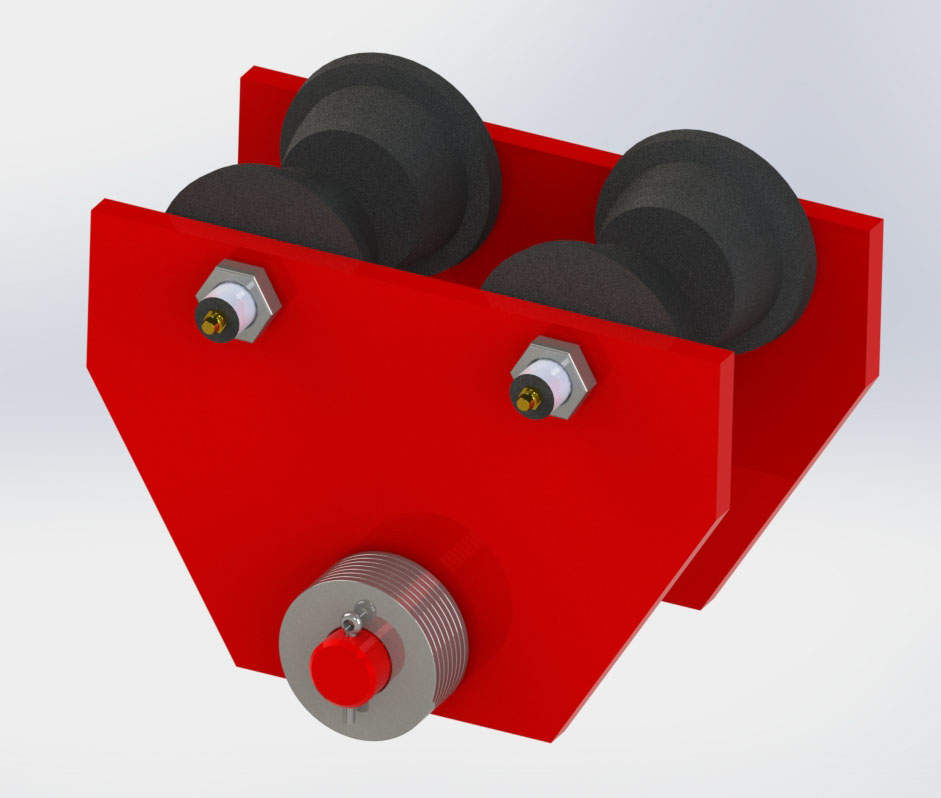

Rolling cranes and V-groove wheels

Wallace cranes are designed to roll when loaded to their full rated capacity. As long as the load does not hit any supporting member, cranes with capacities as much as 10t can be pushed by hand.

Wallace also offers hand-pushed V-groove wheels designed to run on angle-iron track, as well as electric and air-powered units that can move on the same track with steel V-groove casters.

Easily assembled aluminium cranes

Wallace cranes can be quickly assembled using available shop tooling. The comapny’s lightweight all-aluminium units are often hand carried and hand assembled on rooftops.

For heavier units, an overhead crane, a forklift, or a Wallace tripod can be used to assemble the units. The assembly pins can be driven in with a 16oz hammer. All of the assembly instructions are online for 24/7 access.

Winch and pulley adjustment system

Tri-adjustable models can be set to different heights and caster frame spreads.

The Wallace Jack Kit accessory is a winch and pulley system that is mounted onto the crane and used to make height adjustments quickly.

Cranes can also be assembled with either inboard or outboard bracing or in a cantilever configuration.

Cranes for delicate equipment

Standard Wallace cranes have been chosen to move high-value, delicate equipment such as America’s Cup racing sailboats. These are frequently used when overhead cranes are not available (such as in on-site temporary structures) or the equipment needs to be displaced slightly for installation, maintenance and repair.