Magaldi Group, founded in 1929 in Salerno, is a leading manufacturer of industrial systems and plants for bulk material handling at high temperatures in coal-fired power plants, cement industries, waste ash plants, steel plants, foundries and metal refining plants.

Magaldi Group’s mission is to design, manufacture and market reliable, high-quality systems that provide environmentally sustainable industrial solutions worldwide.

Dry bottom ash extraction system

The Magaldi Ash Cooler (MAC®) is a patented system for dry extraction, air cooling and mechanical handling of bottom ash from pulverised coal-fired boilers. With hundreds of installations worldwide since the 1980s, the MAC® is the world’s leading dry bottom ash handling system for utility and industrial boilers of any size, burning any kind of fuel.

The main advantages of the MAC® can be summarised in five points:

- Elimination of water usage in cooling and conveying bottom ash

- Reduction of carbon content in bottom ash

- Recovery of energy from ash and refund to the boiler

- Potential sale of dry, low carbon ash

- Reduction of operational and maintenance costs compared to conventional wet systems

- Ash recycling system

MAR® Magaldi ash recycling is an improvement of the MAC® system for ‘dry’ extraction, cooling and handling of bottom ash from solid fuel fired boilers. That innovative process recycles both ‘dry’ bottom ash and economizer (ECO) ash in the combustion chamber, aiming at turn them into fly ash.

Dry bottom ash, along with ECO ash, can then be diverted to the MAR® system and then injected in the boiler through the coal pulverisers.

Bottom ash post-combustion system

The MAP® Magaldi ash post-combustor is a development of the MAC® system to extract, convey and cool bottom ash and to enhance and control the postcombustion of unburnt particles on the steel belt in case of biomass / RDF co-combustion in pulverised coal-fired (PCF) boilers.

MAP® advantages:

- Boiler efficiency increase, due to the energy gains obtained by the postcombustion of high unburnt carbon content in bottom ash and by the recovery of ash sensible heat and furnace radiation

- Potential increase of co-fuel maximum particle size, leading to capital cost reduction of co-fuel screening and pulverizing system

- O&M cost reduction

- Increased potential for the sale of bottom ash

- Integrated mechanical system for handling all ash from utility & industrial boilers

Integrated mechanical system for handling all ash from utility and industrial boilers

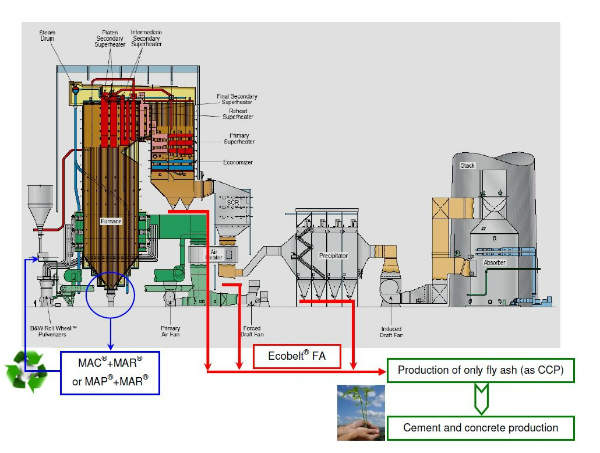

The MAS® Magaldi Ash System is a patented integrated ‘dry’ mechanical system for handling all ash from solid fuel fired boilers, allowing a dependable and economical management for both fly and bottom ash.

The MAS® comprises three subsystems, as follows:

- The mechanical transportation of fly ash through the Magaldi Ecobelt® FA.

- The MAC® system, for ‘dry’ extraction, cooling and handling of bottom ash.

- The MAR® system, for ‘dry’ bottom ash and economizer ash recycling in the combustion chamber, to convert them into fly ash.

Steel belt conveyor for fly ash

The Magaldi Ecobelt® FA is a mechanical conveyor designed for handling fly ash from the hoppers located along the flue gas path, including economiser (ECO), selective catalytic reactor (SCR), air heaters (AH) and electrostatic precipitator (ESP) or baghouse.

Mill rejects mechanical handling system

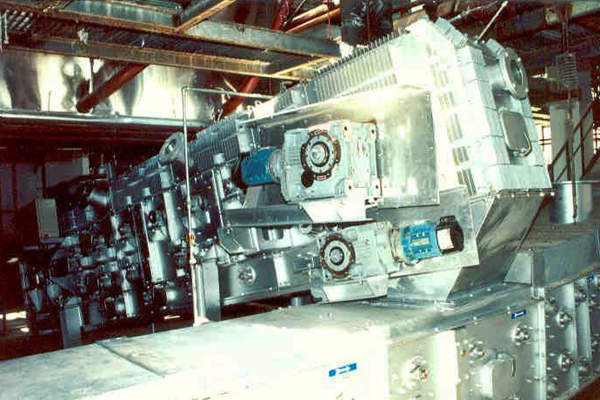

The Magaldi mill rejects system (MRS®) is a patented fully automatic steel-belt conveying system, designed to dry handle mill rejects from coal mills to storage silos. The system uses the reliable, high-performance Magaldi Superbelt®.

As no water is required in MRS® operations, any environmental problems associated with wet systems are avoided, as are plugging problems which may occur either in sluice or pneumatic conveying systems.

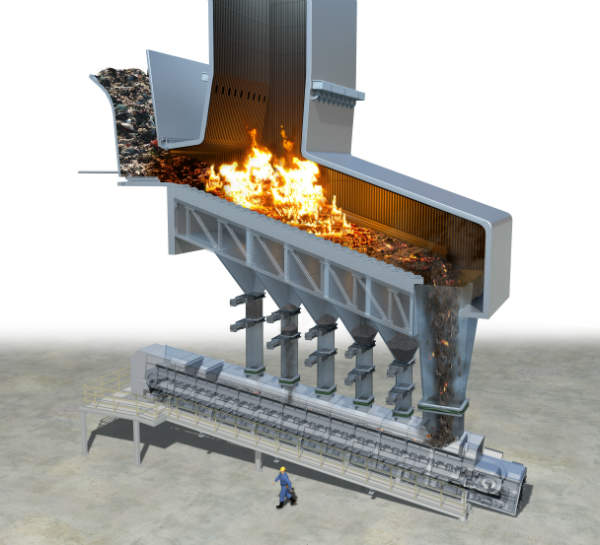

Fluidized bed ash extraction system

The patented Fluimac® system is an innovative system for the dry handling of bed ash from fluidised bed combustion (FBC) boilers.

The Fluimac® system is characterised by low operation and maintenance requirements and no water usage during ash processing. Using heat recovery from the ash, the Fluimac® system is also able to increase boiler efficiency.

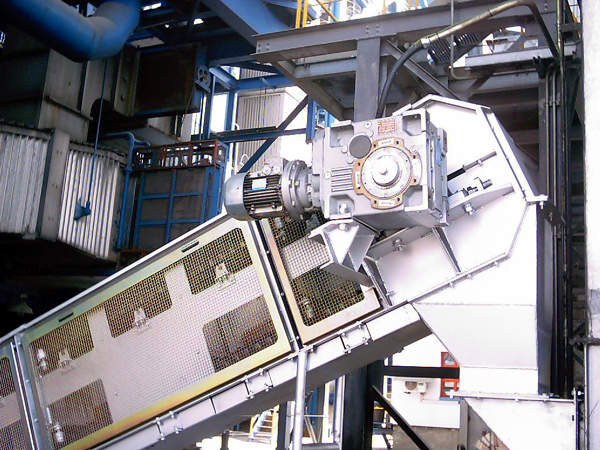

Dustproof steel belt conveyor

The Magaldi Ecobelt® is the ideal conveyor for handling hot materials, aggressive chemicals, heavy or sharp products, ensuring a safe and environmental friendly operation.

The key component of the Magaldi Ecobelt® is the Magaldi Superbelt®, completely enclosed in a steel casing to prevent dust dispersion to the environment. A simple mechanical self-cleaning device removes the fine residuals from the bottom of the casing.

The Magaldi O-chain® is a chain conveyor enclosed in an independent casing, tailored around the Magaldi Ecobelt® tail section. Its function is to receive the fine residuals, taken from the Ecobelt® bottom by the self-cleaning device and to reload them onto the Magaldi Superbelt®.

Dry bottom ash handling conveyor for waste incinerators

The Magaldi Ecobelt® WA is a conveyor for dry extraction, cooling and handling of bottom ash produced by waste incinerators, ensuring a safe and dependable operation in an enclosed environment.