Hilman Rollers are low-profile, high-capacity moving devices that can be used to move a multitude of things. Ranging in size from small machinery to entire bridges, buildings and offshore oil rigs, Hilman Rollers have moved some of the largest objects in the world. Used as a temporary means for moving a heavy structure, repetitively in assembly line applications or as a permanent installation on-board an oil-rig, Hilman Rollers are known throughout the world for their quality and durability.

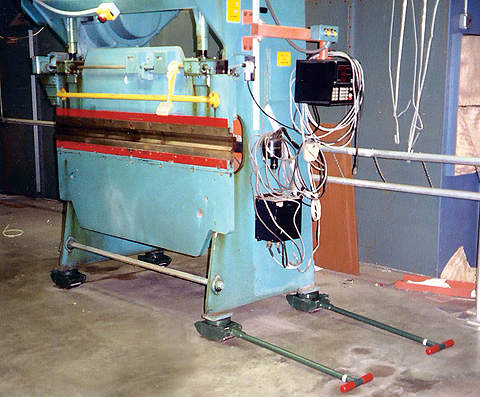

High-capacity conveyors for moving power equipment

All Hilman Rollers utilize the endless chain principle; which features a chain of steel rolls capable of rotating about a central load-bearing, steel plate. The result is a product that performs as a low friction, high-capacity conveyor.

Often referred to as rollers, dollies, skates, machinery movers and turtles, Hilman has become a brand name when referring to this type of equipment. We offer standard model rollers with capacities from 0.5t up to 1,000t. All Hilman Rollers are rated in metric tons and most standard models carry a safety factor of 2-to-1.

High-capacity rollers

Since 1953, the Hill family has maintained the highest standards of quality that has made Hilman Incorporated the world’s leading manufacturer of high-capacity rollers. These days we are known for more than just our rollers. We can include drive systems, integrated hydraulics, steel fabrications and steel tracks to name but a few ancillary items that function with or alongside the rollers we provide.

Our newest product, Hilman Traksporter, allows users to move the heavyweights via remote control. Our production facility contains full welding capability, multiple overhead cranes and full CNC machine and turning equipment.

Quality-approved rollers

Hilman Rollers have gained the approval of DNV, Lloyds, BV, SGS, ABS and other third-party certifications; they are also ISO-9000 approved.

Our staff is capable of going just about anywhere in the world to work on, service or lend guidance to your projects.