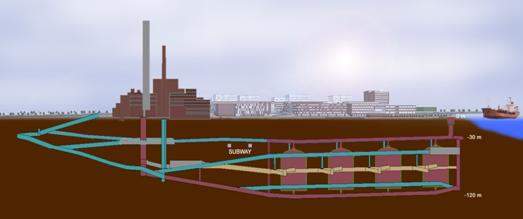

When it comes to advanced storage solutions for bulk solids, ESI Eurosilo can support you with decades of experience in engineering and turnkey delivery of mammoth silos. These fully enclosed storage facilities, ranging from 1,000m3 to 100,000m3, offer maximum control in material handling, while saving operational costs and valuable space for expansion. With over 120 units built around the world, ESI Eurosilo serves a variety of customers in today’s major industries, from the power industry to basic chemicals and agriculture. As a leading company in our field, our aim is to deliver technology that will help you meet economical, physical and environmental demands in the best possible way.

The Eurosilo® concept

The Eurosilo® concept combines enclosed storage with a choice of ingenious reclaim mechanisms. These mechanisms are designed to enable reclamation of even such sticky bulk solids as FGD gypsum, making the notorious ‘flow-no flow’ criteria a thing of the past. Even more impressively, this proven concept meets the requirements of environmental protection agencies worldwide.

Accumulating more than 40 years of experience, ESI Eurosilo has built over 120 units around the world.

Operation principles

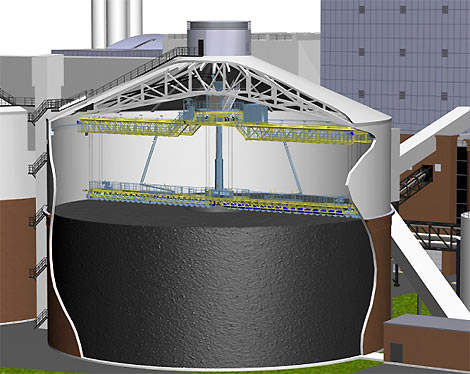

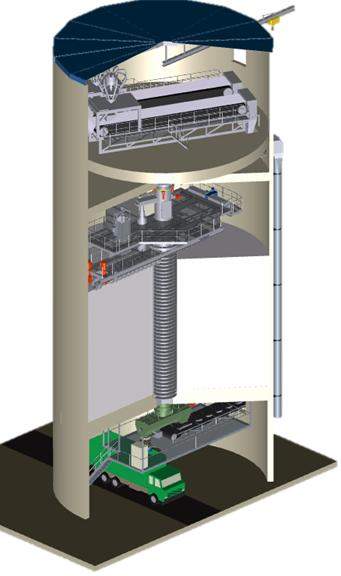

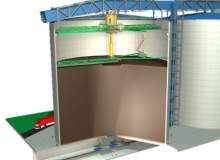

In the Eurosilo system, the bulk solid content accumulates in horizontal layers. The material enters the silo through the top centre of the silo, descends through a telescopic spout and is distributed uniformly by means of a screw conveyor system suspended from a slewing-bridge structure. The Eurosilo system offers four main reclaim methods:

- Core Flow forcoal storage

- Core Flow with Central Column for coal, potato starch and soybeans

- Slotted Central Column for cohesive materials like fertiliser, salt and FGD gypsum

- Shutter Column System for materials with a very small particle size like fly ash

Options

Eurosilos are custom-made to the customer’s requirements. A range of options are available:

- The silo can be built with a steel structure, a wooden inner wall and standard outer wall cladding, as a slip-formed concrete silo or as a steel tank. Tracing and/or insulation of the outer wall are also available

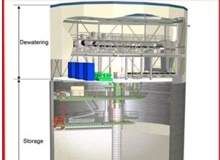

- Additional dewatering can be achieved through the silo drainage and by installing an optional vacuum unit

- The systems can be equipped with remote control operation, based on data bus systems

- Extended silo structures for mounting equipment, for example, a dewatering station at the top of an FGD gypsum silo

- Truck and train loading facilities, including a weighing system, can be constructed directly below the silo

- These options are a selection of many possibilities. Each silo can be customized to your needs and requirements

Why Eurosilo?

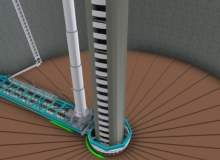

The patented Eurosilo system offers many significant advantages. Importantly, the system causes no pollution through dust or groundwater percolation. The system also prevents moisture increase by external influences, which keeps product degradation to an absolute minimum. In addition, the Eurosilo system requires considerably less groundspace than other storage systems: up to 60% less space than open stockpiles for the same storage capacity!

On top of that, the Eurosilo system enables smooth reclamation of cohesive materials, such as FGD gypsum, even after three months. Another major advantage is the option for Dynamic Coal Blending, reclaiming different grades of coal from multiple silos at a controlled rate. The system also ensures a high availability of equipment. Most importantly however, the system offers huge cost savings, due to low operating, maintenance and waste costs.

Storage facilities for coal fired power plants

With the limited economic perspective of alternative energy and a global hesitance to nuclear power, we believe that coal-based power generation will maintain its prominent position for years to come. The increasing need for power of today’s society is however rivalled by the growing environmental concern and the subsequent legislation. With innovative storage facilities, we support customers worldwide to make these ends meet. A range of robust solutions is designed to significantly improve cost-efficiency, while enhancing long-term sustainability, safety and productivity.

The innovative storage solution for coal

The Eurosilo system addresses all critical issues of coal storage in an innovative and cost-efficient way. Conventional open-air storage leads to costly environmental drawbacks and loss of calorific value. Also, it requires sufficient space at your plant site. Enclosed storage in a highly-automated Eurosilo solves all these problems at the smallest possible footprint. The system offers a storage capacity of up to 100,000m³ so far. The coal is fed from the top into a chute through which it reaches the auger frame on the coal surface. Two parallel screw conveyors distribute the material over the entire area while the auger frame rotates. Reclaiming is done at the bottom of the silo, while the screw conveyors rotate in reverse to feed coal into the formed core flow.

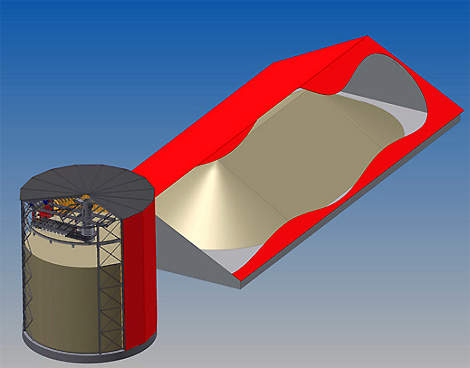

Cost-efficient all-in-one solution for FGD gypsum

The Eurosilo storage solution for FGD gypsum incorporates three vital functions at the smallest possible footprint. Dewatering, storage and load out are all located in one fully-automated silo system. Compared to shed storage, this adds up to numerous advantages. Instead of a separate dewatering, storage and load out facility – needing operators, power shovels and transport – there is only one cost-effective solution. Not only will it reduce the required space to a third, it will also minimize the necessary headcount and improve the operational reliability in handling FGD gypsum. Compared to storage silos equipped with a bottom discharge plow feeder system, our system increases the storage period from a few days to more than three months without the risk of block-ups.