Alimak rack and pinion industrial lifts / elevators maintains overhaul, maintenance and inspection services for power plants all over the world. The lifts are designed to operate in demanding industrial environments, outdoors or indoors and need no expensive shafts or lift rooms. They can easily be fitted on new as well as existing structures.

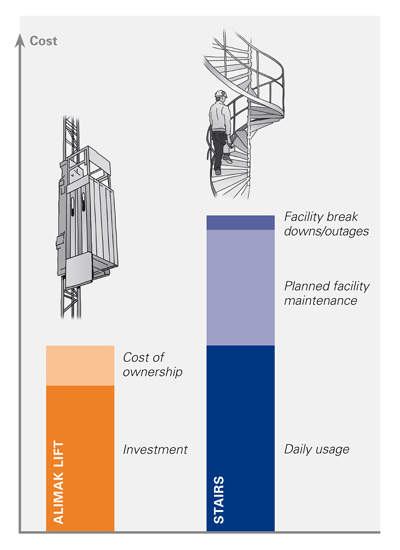

Improving access to your plant with Alimak rack and pinion lifts increases labour efficiency, reducing the labour required to complete planned outages and routine maintenance. It also gets the plant back online faster, so utilities can start generating additional power – and revenue – sooner. An Alimak lift is a powerful investment that pays off quickly.

Industrial lifts / elevators for power plants

Every power plant is striving towards:

- Increasing plant output

- Improving efficiency

- Increasing availability

- Reducing operating costs to a minimum

It is of paramount importance to identify potential sources of failure to provide preventive maintenance and – should an unplanned production stop occur – being able to quickly respond to the failure.

To install a lift is often the least expensive way to decrease downtime. Alimak industrial lifts are reliable, efficient, durable and offer a low cost of ownership.

Safe rack and pinion lifts for boilers, chimneys and reactors

Regardless of the source of energy, whether coal-fired, gas-fired, combined cycle, refuse-fired, nuclear, hydroelectric or wind, Alimak lifts provide safe and easy access where required.

Alimak lifts are found on:

- Absorbers

- Accumulator tanks

- Boilers

- Chimneys

- Coal handling facilities

- Cooling towers

- Crushers

- Heat recovery steam generators

- Nuclear reactors

- Precipitators

- Selective catalytic reduction systems

- Scrubbers

- Silos

- Solar towers

- Water dam shafts

- Wind turbines

Alimak rack and pinion drive system

The Alimak rack and pinion drive system offers a number of advantages that can be translated into substantial economic benefits. They are designed for demanding industrial environments. No expensive machine room is required as the lift carries its own machinery and no load bearing lift shaft is required. Installations can be inside or outside buildings and also on curved or inclined surfaces.

The lifts can easily be retrofitted to existing structures and have a very narrow and streamlined profile, which is invaluable where space is at a premium. A simple drive principle means easier maintenance and lower service costs and there is practically no restriction in lifting height. The car can be brought down by gravity at controlled speed in the event of a power failure.

Alimak lifts – product range

- Rack & Pinion Elevator Series – shaftless, machine room-less

Technical Data:

Drive: Rack & Pinion

Capacity: 300kg – 12,000kg

Ex class: Safe area, ATEX, NEC, NEC Dust

Lifting height: up to 250m

- Traction Elevator Series – shaft, machine room / machine room-less

Technical Data:

Drive: Traction

Capacity: 300kg – 10,000kg

Ex class: Safe area, ATEX

Lifting height: up to 60m

- Customised Solutions – shaftless, machine room-less, shaft, machine room

Technical Data:

Drive: Rack & Pinion, traction

Capacity: 300kg – 24,000kg

Ex class: Safe area, ATEX, NEC, NEC Dust

Lifting height: practically unlimited (700m has been built)

About Alimak

Alimak is a global market leader and pioneer in designing, developing, manufacturing and servicing industrial rack and pinion vertical access solutions.

The company offers high-quality rack and pinion and traction elevators, hoists and platforms primarily for industrial and construction sectors.

Alimak has a well-established global sales, services and distribution network across more than 90 countries. The company has a large global installed base of over 23,000 units, which proves expert knowledge of all industrial application areas.

Founded in 1948, Alimak is based in Stockholm, Sweden, and employs over 1,200 people across the world.