Promat HPI offers insulation solutions help to minimise energy losses in all forms of power generation and ensure optimised thermal management.

Eliminating energy losses with thermal insulation

Effective thermal insulation keeps energy losses to an absolute minimum. Promat HPI offers a comprehensive range of high-temperature insulation products.

Microtherm® microporous insulation is one of the very best performing thermal insulation in the world. At high-temperatures, it comfortably out-performs conventional insulation products. A Microtherm® system is always thinner and lighter than rival products.

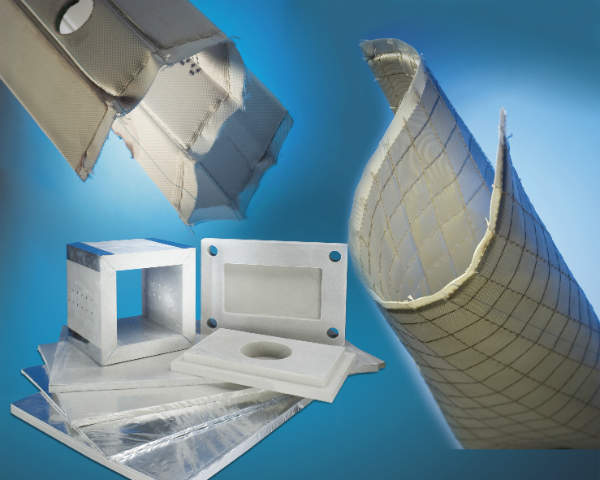

Promat HPI’s microporous product range includes a wide selection of solid and flexible glass cloth covered panels, PROMALIGHT® boards, moulded pipe sections (MPS), and also granular free flowing material. All products can be used continuously at 1,000°C without deterioration.

Other products available include the best-performing Calcium Silicate range, high-temperature fibres and a range of castable ceramics and lightweight insulation bricks.

Insulation in power generation

Whether powered by fossil fuels or nuclear sources, a power station creates heat to produce steam for turbines to generate electricity. In any thermal process, the operational efficiency will be dramatically influenced by efficient control of heat loss by the use of high-performance insulation. Microtherm® high-temperature thermal insulation has exceptionally stable performance at temperatures up to 1,000°C and offers the ideal solution for compact thermal protection.

When multiple pipes are routed in close proximity, a Microtherm® insulation system that is one quarter the thickness of a conventional insulation system allows individual protection of pipes. MICROTHERM® MPS and segments, MICROTHERM® SLATTED, MICROTHERM® QUILTED and SLIMFLEX® rolls all allow fast and simple assembly and guarantee optimum thermal performance and control of process temperatures.

Other key areas where space is restricted, such as turbine ends, also benefit from the compact and lightweight protection of Microtherm® flexible insulation.

Insulation systems for fuel cells

Fuel cells provide clean energy production by running on hydrogen, which can be sustainably generated from a wide variety of fuel sources. Promat HPI insulation systems for fuel cells are the lightest and most compact available, leading to a smaller fuel cell unit size and shipping weight.

Molten Carbonate Fuel Cells run at temperatures in excess of 600°C, with Solid Oxide Fuel Cells running even hotter at up to 1,000°C. Promat HPI insulation products are used to insulate the outer casings and reduce surface temperatures to no more than 50°C for personal safety. Because the insulation is more efficient than other types, the overall footprint of the fuel cell assembly is kept to an absolute minimum.

For maximum effectiveness, Promat HPI insulation systems normally combine different microporous products, including FREEFLOW®, PROMALIGHT® 1000R machined parts, MICROTHERM® QUILTED and MICROTHERM® SLATTED panels with calcium silicates products such as DURATEC® 1000 and MONALITE® M1A for conceptual and structural use and high-temperature wools such as PROMAGLAF blanket, paper or felt for sealing the complete assembly or filling small gaps.

As Silica might be perceived as a contaminant material in some stack designs, PROMALIGHT® 1200 grade materials are an alternative insulation based on Alumina. It has the additional advantage of an upper working limit of 1,200°C.

Because fuel reformers also run at high-temperatures, performance can be optimised by insulation with a Promat HPI system. The reformers used for small PEM fuel cells are often compact and intricate in shape and difficult to configure conventional insulation materials to fit to them. In these instances, a pourable, granular, microporous insulation such as FREEFLOW® provides the optimum solution.

The balance of plant (BOP) comprises all the auxiliary equipment required to ensure that the fuel cell can behave as a reliable power source. BOP equipment has a critical effect on overall unit efficiency. Piping systems and all cylindrical components are insulated using either Microtherm® Moulded Pipe Sections or Microtherm® Flexible Panels.

Promat HPI services and support

Promat HPI was created by the merger of Microtherm® and the former Promat High-Temperature Insulation, both market leading brands for more than four decades.

Promat HPI offers the most versatile product range on the market, backed by the very best technical and commercial support. R&D facilities are based in Belgium and the applications team can provide full product and system development assistance as well as performance tests and support for testing and certification. Technical help is available from initial problem assessment through to final installation or volume production.