Eagle Filters is a company who specialises in providing air inlet filters for gas turbine power plants.

As a result of Eagle Filters extensive R&D in co-operation with filter material manufacturers and research institutes, we have a new range of air filters especially designed for gas turbine applications. In these products we have successfully combined very high mechanical stability, excellent filtration and aerodynamic capabilities.

- TurboMaster, to replace conventional pulse-jet filters

- PanelS, pre-filters for static air intake systems

- EFiCELL, fine filters for static air intake systems

All Eagle Filters products are designed to meet international standards, including EN 779 and are compliant with current EC safety and environmental regulations.

With its experience and wide knowledge of filtration, Eagle Filters can help customers to find a new and innovative way to solve filtration problems in both self-cleaning and static filtration systems.

TURBOMASTER – STATIC REPLACEMENT FILTERS INSTEAD OF INEFFECTIVE SELF-CLEANING (PULSE) FILTERS

In gas turbine air intake applications pulse filters were originally used in dry desert areas to ensure plant operation under sand storm conditions rather than to maintain high filtration efficiency. When an environment is moist or the filtered dust consists of urban or industrial emissions, e.g. unburned hydrocarbons, soot etc, the pulse filters suffer and are inadequate in operation both economically and technically. Ironically, the most common problem faced when using “self-cleaning filters” in urban areas is early clogging (causing short serviceable-life) of filter.

Fortunately any pulse clean system can be easily replaced with Eagle Filters static cartridge filter. Now it is possible to have a filtration system that is equivalent in efficiency to a static filter system without compromising dP, by installing TurboMaster cartridge filter. The serviceable life of TurboMaster is longer than pulse filter cartridges or regular static fine filter elements due to the lower volume of airflow associated with pulse system design.

According to field data, by using TurboMaster, it is possible to achieve substantial economical and operational improvements and save even hundreds of thousand of dollars, each year – in each unit.

SNAPON – FAST AND AIRTIGHT FILTER FIXING METHOD FOR STATIC INSTALLATIONS

Eagle Filters’ SnapOn system is designed so that the pre- and fine filter elements are fixed together with an airtight seal. When PanelS pre-filters and EfiCell fine filters are supplied with the SnapOn fixing method, they form a perfect filtering system.

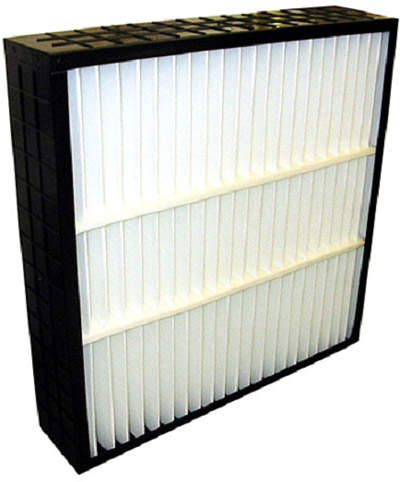

PANELS PRE-FILTERS SAVE MAINTENANCE AND ENERGY COSTS

PanelS pre-filter is the first stage of the SnapOn method. It replaces leaky pre-filter pads, it is comparable to pocket filters dust holding capacity, it is small in size, it has a rigid construction, is water repellent and is unaffected by turbulence.

PanelS has a proven record of a long serviceable life and high arrestance in several gas turbine power plants in the most demanding environmental conditions. In 95% of cases PanelS can replace existing pre-filters without any change of construction to the existing mounting frame.

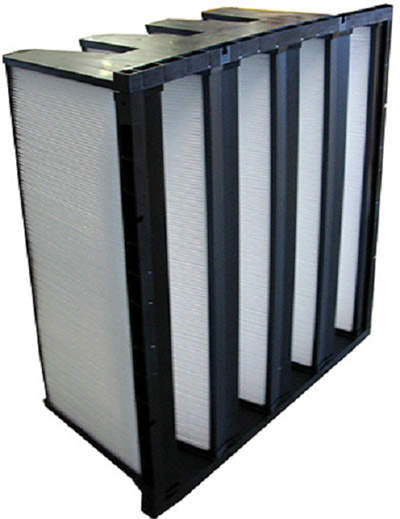

EFICELL FINE FILTER – HIGH EFFICIENCY AND EXCELLENT AERODYNAMICS

The second stage of Snap-On is EfiCell compact cell air filter. It has been developed specifically for demanding processes and difficult environmental conditions. EfiCell filters are the best solution in protecting a gas turbine when located by rivers or sea; where the relative humidity is high; when the environment is dirty, foggy and or rainy. The new synthetic filter material offers high initial efficiency, high bursting pressure, total resistance to moisture, low pressure drop and high dust holding capacity. Eagle Filters’ synthetic filtration material has been developed with higher initial conventional filtration efficiency compared with traditional synthetic filtration material with low conventional efficiency and high electrostatic charge.