As part of a major life extension programme, Franke-Filter has provided a first-class engineering solution to the on-running oil mist problems of a large nuclear power plant.

With a number of issues such as low levels of vacuum in the lube oil system and oil mist discharge into the environment, the operator decided to solve the problems by replacing the aged existing system, by an up-to-date oil mist separator from Franke-Filter.

"It was a win-win situation from the beginning. A comprehensive on-site survey was undertaken, flow and capacity values noted, and a number of sketches were made of the intended installation area.

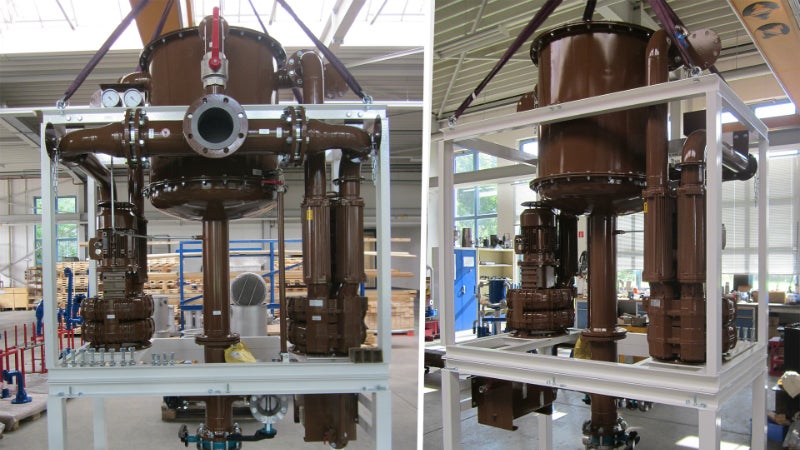

Drawings were produced by our construction team and a suitable design was put forward, together with an up-dated specification covering the electrical and mechanical elements of the oil mist separator.

As a result, the oil mist problems have been eliminated and our customer is now able to adjust the vacuum in the three separate chambers in the lube oil system individually with just one demister Unit. We now have a very satisfied customer." says the responsible technical consultant from Franke-Filter.