For over 50 years, Dow Water & Process Solutions has been a leading supplier of advanced water purification and separation technologies worldwide. Dow offers solutions for all aspects of water treatment, from system design assistance, to long-term system optimization and troubleshooting. Dow technologies are widely recognized by leading power companies for their quality and exceptional performance.

Water purification and separation for power generation applications

Reverse osmosis and ion exchange resins technologies from Dow Water & Process Solutions are helping the world’s leading energy companies drive down the cost — and environmental footprint — of generating power.

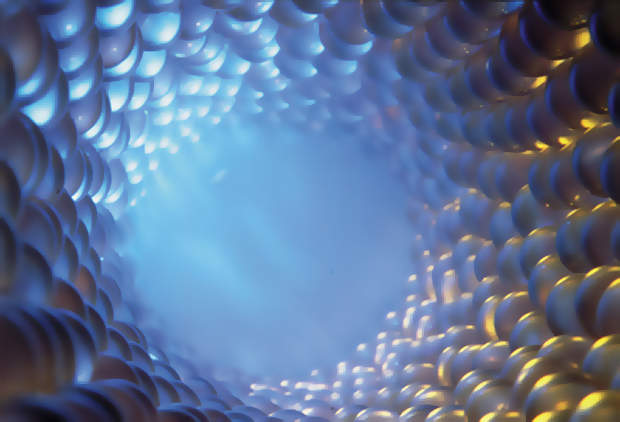

Reverse osmosis elements

Delivering higher total dissolved solids rejection at lower pressures, Dow reverse osmosis (RO) technologies are widely used for bulk demineralization in steam generation plants. DOW FILMTEC elements are the industry standard in RO, offering high rejection of dissolved solids like silica, superior reliability and longer life.

FILMTEC pioneered automated element rolling in 1994. Since then DOW FILMTEC elements have continually delivered significant increases in active area per element, including wider feed-spacer in 400 SF elements. The patented iLEC interlocking technology, unique to DOW FILMTEC elements, ensures easy, leak-tight installation.

Ion exchange resins

Dow ion exchange resins help to protect nuclear and fossil fuel power generation components from corrosion, decreasing maintenance costs and increasing plant life. Dow offers solutions for boiler make-up and condensate polishing in the conventional island and the trace removal of mercury, boron, and other contaminants in the flue gas desulphurization unit (FGD).

Energy producers worldwide rely on DOW best-in-class ion exchange brands such as AMBERJET, AMBERLITE, MARATHON and MONOSPHERE for demineralization, condensate polishing and other applications. In fact, AMBERLITE resin is the trusted brand for use inside a nuclear island, helping to meet the stringent needs of the nuclear industry.

Dow offers the most comprehensive range of ion exchange resins to the power industry — leading the way in producing uniform particle-sized beads, increasing the efficiency of operation and regeneration, making stronger gel resins for longer life, and supporting a complete array of packed bed technologies to increase recovery and water quality.

Ultrafiltration modules

Dow’s outside in, pressurized ultrafiltration modules offer excellent pre-treatment capabilities for RO and ion exchange systems. A robust pre-treatment system designed around DOW ultrafiltration modules will deliver high-quality, consistent water to your demineralizer, regardless of feed-source variation. You can also expect an increase in the efficiency and longevity of ion exchange resins and RO elements downstream.

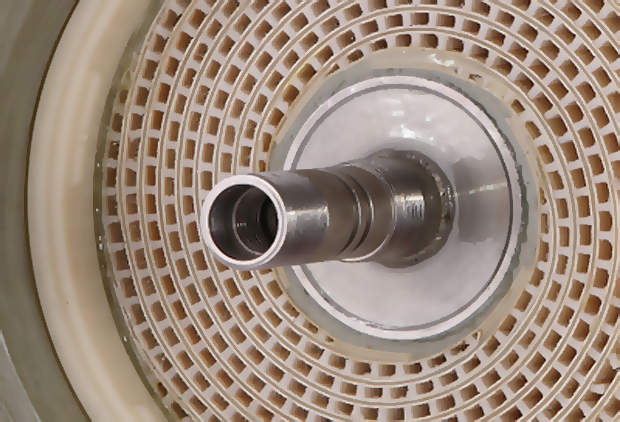

Electrodeionization modules

Electrodeionization (EDI) is a continuous and chemical-free process of removing ionized and ionizable species from feed water, using DC power. The new DOW Electrodeionization 310 module can lower operating costs by up to 15% for electronics manufacturers, refineries, chemical operations and power generation facilities. Its advanced design minimizes system complexity and shrinks the overall system footprint. The module eliminates the need for a brine recirculation loop, lowering both capital and operating costs.

Dow is also one of the only companies to offer spiral-wound EDI, a design innovation that simplifies maintenance, decreases module weight and increases system design flexibility for OEMs.

Technical expertise in water purification and separation technologies

In addition to an extensive product portfolio, Dow Water & Process Solutions offers unparalleled technical expertise. Our technical experts not only assist you with product selection, system design, troubleshooting and product upgrades; they are also industry thought-leaders who are active in nuclear and fossil industry conferences and exhibitions around the world. Look for a Dow presentation or technical paper at your next conference or visit our website to learn more.