Joustoliitin has comprehensive experience in the application of fibre technology and manufacture of unique products. The company was established in Rauma in 1994 and has since acquired solid experience in the products, applications and systems of fibre and textile technology.

Focusing mainly on two main product lines, bellows compensators and technical textiles, Joustoliitin designs and manufactures high-quality products for power generation, process industries and equipment manufacturers.

Joustoliitin is a full-service supplier. The total service package philosophy of the company covers tailored design, manufacture and installation service, as well as inspections and maintenance activities.

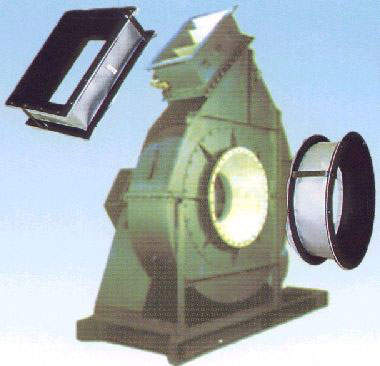

Expansion joints for power plants

Joustoliitin manufactures high-quality expansion joints for power plants, industrial blowers, conveyors and the process industry. We manufacture expansion joints from one-layer ventilation joints to multi-layer joints for demanding use, for use at operating temperatures of up to 1000°C.

Joustoliitin not only manufactures and supplies expansion joints, but also provides consulting services and assistance in all issues related to them. Expansion joints are manufactured using high-quality, special materials that ensure heat and pressure resistance, as well as ensuring a long service life and safe use. We have a large variety of materials which we manufacture ourselves and use the best possible expansion joints for each application.

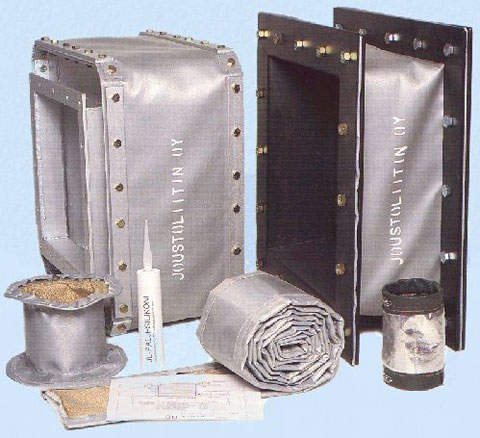

Expansion joints are tailored to the requirements of the customer and the application. Many different shapes are available, from round to rectangular, or any combination of these. Expansion joints are delivered complete with a flange solution chosen on the basis of the application.

Fabric expansion joints

Bellowrap is the fabric expansion joint in roll form. Bellowraps are tailored to the requirements of the application. The starting point in the development of the bellowrap is to ensure fast delivery and swift installation. Bellowraps are delivered complete with installation and connection instructions and all the required connecting materials and tools. Our technical staff also design specialist solutions for challenging operating and installation conditions.

Installation and maintenance of expansion joints

The delivery of the expansions joints can comprise only the fabric parts or also the required steel parts. Special solutions are designed in co-operation with the customer.

We perform in-service inspections of expansion joints for pre-planning of outage, whereby the required expansion joints can be ordered in good time before the outage. Our experienced installation crew installs the expansion joints on a turnkey principle, or provides installation supervision services, as requested by the customer.

Our installation and maintenance service takes care of all installation, maintenance and repair operations that concern expansion joints of canalisation, including:

- Measurement

- Heat flow calculations

- Designing

- Manufacturing

- Installation

- Installation supervision

Installation and spare part service is available nationwide and our quick and flexible service offers short delivery times.