Holz Rubber is a leading supplier of non-metallic expansion joints serving the coal-fired power generation, gas turbine, marine, cement, incineration, nuclear, pulp and paper, refining, petrochemical, and general industrial markets.

Founded in 1935, Holz provides a full range of manufacturing services and a broad selection of elastomers. Our commitment to research and development of high-performance elastomers has led to a complete product offering that provides engineered solutions to the most severe air / gas handling applications.

Specialised expansion joints

Holz Rubber can produce custom and specialty expansion joints to specifically meet unusual or tough industrial circumstances, from unique fits to special-material needs. With Teflon, fabric and a full range of elastomeric expansion joints available, Holz Rubber’s products can sustain extreme conditions and duress.

For high-temperature applications or specialized situations such as petrochemical, power plant, or wastewater treatment, Holz Rubber delivers quality and functionality at competitive prices.

Fabric expansion joints

Holz Rubber’s fabric expansion joints are durable and flexible, making them ideal for a variety of piping and ducting solutions. We manufacture fabric expansion joints using a unique mix of materials for maximum reinforcement and durability, including alloy wire, fiberglass, aramid, polyester and flame-retardant meta-aramids.

Depending on the style, fabric expansion joints can perform under a number of difficult operating conditions, including harsh chemical environments, temperatures up to 2,000°F, applications with extreme movements, or contaminants in the gas stream. Experienced in power generation, chemical processing, waste water, oil and gas, as well as most other industrial applications, Holz Rubber’s product engineers can assure you get the right part for the application.

PTFE (Teflon) expansion joints

Holz Rubber’s other non-metal expansion joint offering utilizes PTFE (commonly known as Teflon) for moulded expansion joints. As spool-type flexible couplings, PTFE moulded expansion joints compensate for movement and bate noise in severe corrosive environments. They provide ideal materials for petrochemical, power plant, or wastewater expansion joint needs, including any replacement of any metallic joints or PTFE-lined materials.

Delivered complete and ready for immediate field installation, Holz Rubber’s PTFE moulded expansion joints bring the best of design, materials selection, and manufacturing for a reliable high-quality product.

Insulating expansion joints

Holz Rubber’s complete line of sealing technologies is coupled with thermal management products to create the most flexible, cost-effective and longest-lasting expansion joints on the market today. High-temperature insulating materials include engineered coated fabrics, needled fiberglass and silica blankets.

Application-matched air and gas handling products

Holz Rubber’s specially engineered compounds and construction techniques are directed at solving today’s air and gas handling problems such as high-acid concentrations, ammonia slip, ash accumulation and large movements.

Detailed construction drawings, dedicated engineering resources, field service, field supervision and proven material technology add up to a viable product designed correctly the first time and shipped on time to meet the most demanding construction schedules.

Expansion joints for flue gas desulphurization (FGD) applications

Flue gas desulphurization is one of the most challenging applications for expansion joints. Holz has spent many years developing a product suitable for long-term use in this harsh environment. Our specially designed FGD flex element utilizes a robust FKM outer flex element that is resistant to aggressive acids and proven to provide integrity against pressure shifts up to 5psig along with a zero porosity PTFE barrier, acting as the inner gas seal. The combination of advanced materials ensures long life and predictable performance.

Rubber, acid-resistant expansion joints

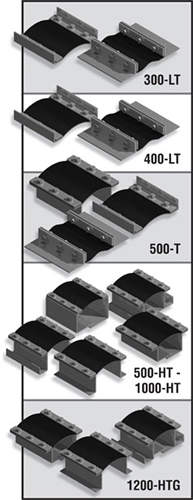

Holz Rubber’s 300-LT expansion joints can be used in wet or dry service up to 400ºF and 5psig. The 300-LT range can be manufactured from neoprene, EPDM or chlorobutyl rubber and is reinforced with single or multiple layers of woven fabric or knitted wire. 300-LT expansion joints are typically found on bag houses, FD fans, wet or dry scrubbers and precipitators.

The expansion joints are offered in either belt or flanged configurations and are designed to operate without a flow liner, except where abrasion or high velocity flow is anticipated. 300-LT expansion joints are designed to allow external insulation over the flex element if desired.

Dupont-certified Viton expansion joints

Holz Rubber’s 400-LT expansion joints can be used in wet or dry service up to 400ºF and 5psig. The 400-LT range is constructed using Dupont-certified Viton rubber and reinforced with a single multiple layer of woven fabric or knitted wire. An additional FEP or PTFE gas barrier can also be added for increased chemical resistance especially in applications where ammonia slip is expected.

400-LT expansion joints are typically found on air heater gas outlets, bag houses, precipitators, induced draft fans, wet or dry scrubbers and stack breeching ducts. 400-LT can also see excursion temperatures up to 750ºF in the case of air heater failure for a short duration without permanent damage to the elastomer.