DEKOMTE manufactures and supplies fabric and metal expansion joints as well as corrugated hoses and accessories. The emphasis of the product range is on fabric expansion joints. We have several patents and numerous in-house developments in this area. Quality processing appropriate to the material being used guarantees the highest reliability. If required, DEKOMTE can offer complete project planning for expansion joints including selection of components and optimum design as a specialised engineering service. Afterwards, the proven DEKOMTE service team is available to you at any time. It will help you in case of minor problems as well as with the rapid and problem-free replacement of complete expansion joints.

FABRIC EXPANSION JOINTS – GASEOUS MEDIA, SUCH AS AIR, EXHAUST GASES OR SOLVENT FUMES

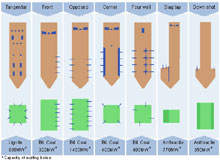

DEKOMTE supplies quality fabric expansion joints. Many different materials of the highest quality are used for this. In principle, fabric expansion joints are best for gaseous media, such as air, exhaust gases or solvent fumes, for operation below the dew point (also with a percentage of acids) and for abrasive exhaust gases (e.g. containing coal dust). Fireproof expansion joints at ducts through walls and ceilings with fire-protection requirements withstand flames for 90mins and more in accordance with DIN 4102.

Only quality processing appropriate to the material being used guarantees the highest reliability. For example, the nuclear power sector has strict regulatory requirements. DEKOMTE has the required certificates for radiation resistant materials. If required, DEKOMTE can offer project planning for expansion joints including selection of components and optimum design as a specialised engineering service. Furthermore, the proven DEKOMTE customer service is always available. DEKOMTE will help you in case of unexpected problems as well as with the rapid replacement of complete expansion joints.

STEEL EXPANSION JOINTS – PIPELINE TECHNOLOGY

Metal expansion joints are indispensable elements for pipeline technology. They are used to compensate for changes in length, which arise in pipelines from temperature differences. In addition, they are able to absorb vibrations arising from pumps, motors, compressors or turbines. Axial, lateral or angular movements can be compensated depending on the specific situation, and we are happy to advise you on the best type of compensation.

DEKOMTE stainless steel expansion joints are manufactured of single-walled or multi-walled bellows. The standard designs listed in the following tables provide an overview of our range and can aid you in your design considerations. However, we would recommend that you provide us with detailed information on each individual use as we can then technically optimise the possible expansion joints taking account of movements, pressure, temperature etc. which usually leads to lower costs as well.

CORRUGATED HOSES – ALL-LIQUID AND GASEOUS MEDIA

DEKOMTE corrugated hoses can be used for practically all-liquid and gaseous media as well as pumpable solids. Our corrugated hoses are manufactured from butt-welded stainless steel pipe, which has been corrugated by cold forming with the most up-to-date procedure. One or two braidings with stainless steel wire provide for appropriate pressure resistance and external mechanical protection.

PLANNING AND INSTALLATION

If required, we can offer complete project planning from the initial sketch to maintenance of the expansion joint as a specialised engineering service. DEKOMTE is DIN EN ISO 9001 and RAL registered.

The firm of DEKOMTE de Temple Kompensator-Technik GmbH was founded at a time when the requirements on expansion joints were rising to an unprecedented degree. In 1978 the company’s founder, Günther de Temple, continued a family tradition under the motto "from regulator to expansion joint" as the de Temple name had already been associated with reliable steam engine regulators since 1890. Today, the name of DEKOMTE de Temple stands for high-tech expansion joint technology.