Since its establishment in 1995, LAMTEC has expanded itself into a leading company in combustion management, sensor technology and flame monitoring systems. LAMTEC’s products control and monitor combustion, and compensate disturbance variable, while being fail-safe and reliable at the same time.

LAMTEC offers solutions for applications including electronic burner control units, burner and air compound regulators, flame monitoring systems, measuring systems for oxygen (O2) measurement and unburnt gases, carbon monoxide/hydrogen (CO/H2) and volume measurement equipments, which have been specially designed for short measuring distances, for combustion of all kinds.

LAMTEC systems offer efficient products with the highest functionality to provide a universal application with a user-friendly design.

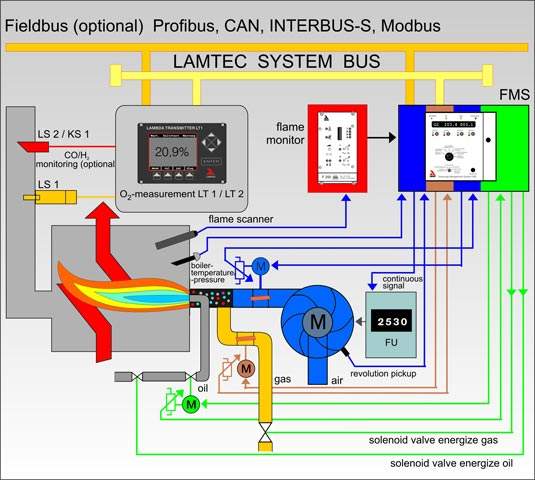

Burner control / fuel and air ratio control

Electronic fuel/air ratio control regulators and complete burner sequence control units from LAMTEC set new benchmarks in combustion control systems. Through a wide variety of possible settings and additional hardware and software options, units can be adapted for nearly all combustion tasks, from simple monoblock burners to complex power stations.

LAMTEC offers a comprehensive range of products, starting with the ETAMATIC for standard combustion facilities, VMS / FMS for high end applications, and complete 19in burner control units.

Flame scanners and monitoring programs

LAMTEC offers complete programs for monitoring flames at single or multiple burner combustion systems with high selectivity and reliability. LAMTEC’s flame monitoring programs have been designed for continuous operation without the need for a mechanical shutter in the following application areas:

- Oil or gas (even combined)

- Pulverised lignite

- Chemical residua and other by-products

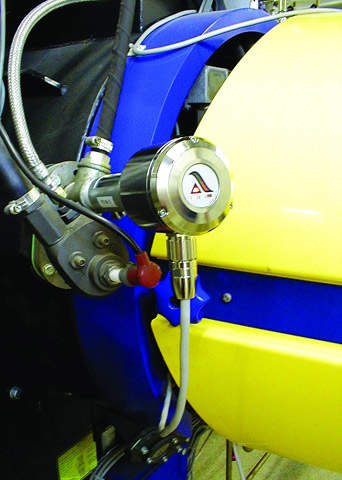

Oxygen measurement and control devices

LAMTEC’s oxygen (O2) measurement devices are based on zirconium oxide (ZrO2) solid electrolyte sensors and are made for measurement directly in-situ. Advantages include short response time and low maintenance needs.

LAMTEC’s products range from cost-efficient devices for monitoring and optimising combustion of oil and gas to high-end devices with TÜV performance tests for applications at power stations for emission measurement. With the O2-control, the combustion disturbance variables are compensated and the fuel/air ratio of the combustion is monitored permanently.

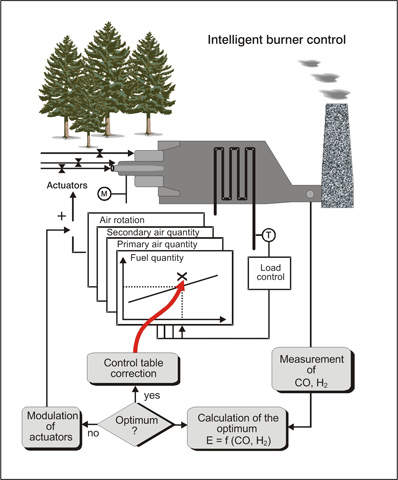

Fuel and air ratio control devices

Since 2004, LAMTEC’s CO/O2-control device has been applied worldwide in more than 500 industrial plants. LAMTEC CO/O2-control is an adaptive fuel and air ratio control, which permanently optimises fuel/air ratio. LAMTEC CO/O2-control brings a burner closer to its optimum efficiency. In total, approximately 12.5 million cubic metres of natural gas were saved in a year, which meant savings of 30,000t of carbon monoxide and a €3.5 million reduction in fuel costs.

Volume flow measurement grid

LAMTEC’s stagnation pressure grid offers:

- Volume measurement of gaseous media, especially combustion air for firing applications up to 400°C

- Minimal loss of differential pressure, compared to conventional technology

- Rectangular and circular grid versions (available)

- Short inlet and outlet-stretch for laminar flow, therefore making retrofitting of an existing plant possible

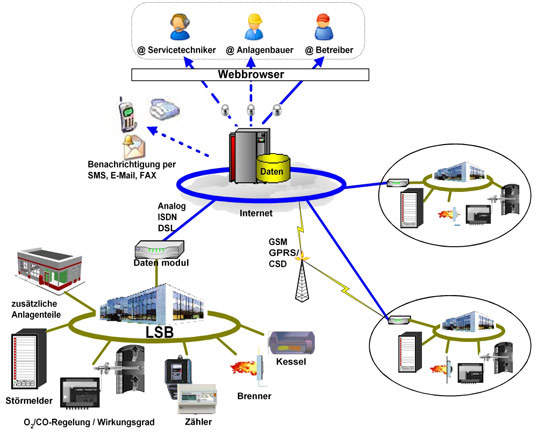

Visualisation and remote monitoring for combustion plants

VISIOCONTROL, a server solution which facilitates bidirectional connections with decentralised installations, offers the option of maintaining contact with several hundreds of installations in parallel, thereby making up-to date information constantly available. The connection between the user, VISIOCONTROL and the plant is transmitted via the Internet. All that is needed is internet access and your usual web browser. Users can additionally receive notifications and messages via mobile phones, fax or email.

Process and fault indicator systems

NEMS is a new value, first value and process indicator system, consisting of individual NEMS16 devices, each with 16 indicator inputs. By networking via LAMTEC-SYSTEM-BUS, it is possible to create an indicator system with a maximum of 1,024 signals (64 individual devices). Each indicator input (18VDC-30VDC) can be converted to fault or process status signal as well as normal open or closed contacts and is displayed by a luminous, three-colour LED on the front panel.