Etr-Unidata is a specialist provider of particulate monitors for measuring dust concentrations. Its advanced technologies provide two unique solutions to the particulate monitoring needs of the power industry:

- Continuous emissions monitoring in connection with local environmental regulations (such as the EU’s Large Combustion Plant Directive)

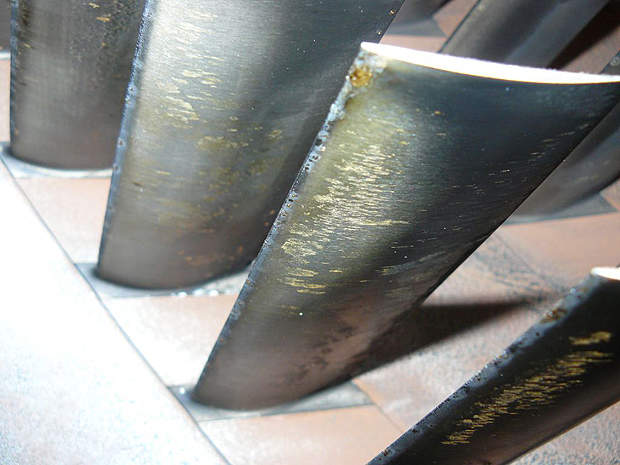

- Gas turbine inlet air filter bank condition monitoring, to ensure the integrity of the filter banks which protect the gas turbine from the damage to plant condition and performance associated with excessive levels of dust in the inlet air

Our instruments are found around the world in fossil fuel power plants, gas turbine power plants, steel mills, paper plants, cement plants, foundries, chemical plants and waste incinerators.

Particulate monitors for continuous emissions monitoring

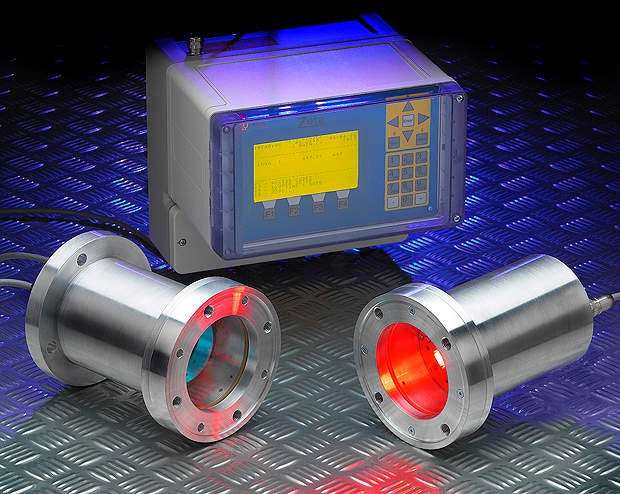

On power generation plants, where owners generally require the highest possible standards of corporate responsibility, the preferred technology for continuous emissions monitors is light scatter, which is generally more sensitive and accurate than alternative approaches. The Zeta 5000 is an advanced light scatter instrument that has raised the standards in particulate monitoring by deploying a patented sensor system which projects a fan of light into the centre of the stack.

This approach increases the stack sampling area many, many times compared with more traditional narrow beam or probe methods (the actual increase will depend on the stack configuration, but 12.5 to 50 times is typical). With the Zeta ‘seeing’ a much more representative sample of the particulate emissions than is possible with conventional designs, sampling uncertainty is minimised and unbiased sampling achieved. The result is much enhanced accuracy and sensitivity. The superior performance is especially important for large ducts and where particulate concentrations are low (such as biomass power stations).

Particulate monitors for biomass baghouse monitoring

The Zeta 5000 is also employed in biomass baghouse monitoring, where its very rapid response time allows a single instrument to monitor multiple baghouse compartments. FilterMonitor software will signal both the onset of filter deterioration and the baghouse compartment, and row in that compartment, in which the deteriorating bag is located.

The Zeta 5000 has been assessed and is certified as suitable for use on large coal-fired combustion plants under the UK Environment Agency’s MCERTS scheme.

Gas turbine filter bank inlet air condition monitoring

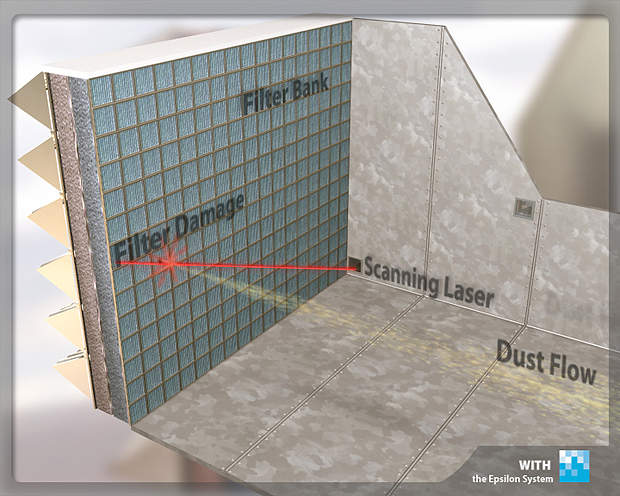

Gas turbine filter bank inlet air condition monitoring on large power plants is not possible using conventional particulate monitoring technologies, because the dust concentrations are extremely low (below ambient air concentrations) and the monitored area is huge (a filter bank can be 180m²). Epsilon therefore combines laser scanning and digital imaging to develop a map of particulate concentration over the filter bank face. Changes in the relative performance of the filters and over time will show where ingress is occurring and which filters need early replacement to avoid compressor damage and/or performance deterioration.

The payback from improved filter performance can be measured in increased output with no increase in fuel usage, and improved plant efficiency. Generating more power in this way means that Epsilon is a ‘Green Technology’. In combined-cycle power generation, just a 1% reduction in fuel consumption can reduce CO2 emissions in a typical plant by 50t per year.

Continuous emissions monitors for small gas turbines

For smaller gas turbines, such as those used to power pumps and compressors on pipelines, and some offshore installations, the filter banks are smaller and spatial resolution is less important. However, with very low dust concentrations, the monitoring problem is securing enough readings to generate a reliable dust count, and conventional dust monitoring technologies are still unsuitable. For such installations, the Zeta 5000, unique amongst continuous emissions monitors in the size of its sampling area, is an alternative and less expensive solution than Epsilon’s digital imaging technology.