Specialising in industrial emissions monitoring, EMCo Air Quality was established in 1995 as a dedicated environmental measurement service. The company remains at the forefront of emission monitoring expertise and excellence.

Monitoring is usually a legal requirement; we like to think of it as an industrial MOT. High-quality emission monitoring data are the key to proving that a process complies with the terms of the PPC or environmental permit. For process operators, knowing that reported data are as accurate and representative as possible is vital. That’s where we come in.

Source emission monitoring

The high-quality emission monitoring data we are able to provide is the product of our experience, expertise, and the state-of-the-art monitoring equipment we use. We are a focused company that aims to be the best at what we do – source emission monitoring.

As a dedicated engineering team we are able to bring years of experience to every project. This level of expertise means we can deliver the high-quality data you need efficiently, safely and with minimum inconvenience to provide a very comprehensive (and cost-effective) service to you.

Emissions monitoring for power stations, boilers and gas turbines

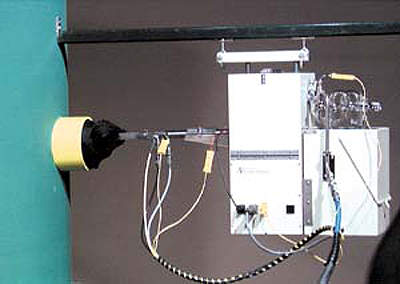

Power generation is a vital part of industry. EMCo has a new mobile sampling laboratory designed for the monitoring of power stations, boilers and gas turbines; we also have a more portable system for less accessible sampling locations.

We undertake work on many steam raising boilers systems and gas turbine facilities (including turbine mapping) and provide online graphic displays of real-time monitoring data to enable gas engine tuning. We also offer the facility for in-depth QAL2 and AST testing. A complete power generation monitoring package is always in keeping with M2 specified standards, and certified as MCERT when required.

Stack emission sampling for power generation suites

EMCo’s expert consultants hold UKAS and MCERTs accreditation for stack emission sampling under BS ISO 17025 for a typical power generation suite:

- Carbon monoxide (BS EN 15058)

- Nitrogen oxides (BS EN 14792)

- NOx monitored hot and wet for gas turbines (BS EN 14792)

- Oxygen (BS EN 14789)

- Moisture (BS EN 14790)

- Sulphur dioxide (BS EN 14791)

- Particulates (BS EN 13284-1)

Stack emission sampling for gas engines and flare stacks

Additional requirements are specified for gas engines and flare stacks under the European Landfill Directive. EMCo Air Quality holds UKAS and MCERTs accreditation for stack emission sampling under BS ISO 17025 for the additional landfill gases:

- Non-methane VOCs (BS EN 13649)

- Total VOCs (EN 12619 or EN 13526)

- Sulphur dioxide (BS EN 14791)

Over many years EMCo has gained wide experience of these processes; this means our engineers can work efficiently to complete these projects. To do so they use a mobile laboratory and extremely accurate instrumental analysers to monitor and provide direct feedback on these emissions.

Consultancy services for emission monitoring

With wide experience of emission monitoring within many industrial sectors we not only have the expertise to undertake your monitoring projects but are able to offer great advice and guidance on many related subjects, including:

- D1 stack height calculations

- Monitoring platform requirements

- Fitting of monitoring ports

- Selection of sample planes

- PPC permit preparation

- Odour monitoring

- CEMS / AMS selection

Accredited stack monitoring and source emission testing

EMCo Air Quality holds the top tier of accreditation available to the stack monitoring industry. We are proud of our UKAS accreditation BS EN 17025 for all the major pollutant parameters. This is supplemented by our MCERT accreditation and accreditation for the application of BS EN 17025 to source emission testing (BS EN 15675).

Emission sampling and testing service

The project flow for new clients is straightforward. A senior consultant will discuss the project with you and offer advice. When all the details are known we will send you a quotation for the complete monitoring package.

The senior project engineer on-site will liaise with the site staff to ensure the project runs smoothly and safely, and with minimum disruption. At the conclusion of the sampling all samples will be properly stored for shipment and sent to UKAS-accredited laboratories for analysis.

The data will be analysed and prepared in a two-part report: part one contains a summary of the results; part two contains detailed monitoring information, calibration and accreditation details.