Founded in 1990, Finex was set up in order to continue the development and manufacture of ion exchange resins, which was initially started by Finnsugar.

Since then, our product range has expanded remarkably, and our expertise in ion exchange resin technology has led to entirely new products and applications.

Finex is based in Kotka, located on the south coast of Finland, 130km east of Helsinki.

Tailor-made performance polymers and ion exchange resins

We manufacture tailor-made performance polymers and ion exchange resins for our customers. We supply specialty products to three types of business areas, all across the globe:

- Powdered resins used for condensate polishing, including in nuclear power stations

- Chromatographic separation resins used for foodstuffs and the sweetener industry

- Special polymers used as fillers for the investment casting industry, whose customers serve the aeronautical, gas turbine and other manufacturing industries

Powdered resins

Powdered resins have a number of uses in water treatment for several industries. They form a solid basis for many applications, from nuclear power plants to more conventional uses.

They can be delivered as a separate cation or anion, as well as a ready-made mixture with the cation/anion ratio optimised specifically for your application.

One of the most important properties for powdered resin mixtures is floc-formation. When the resin particle size falls below 50 microns, the attraction forces between cation and anion increase considerably. In an aqueous suspension, they form a bulky and porous floc, occupying three to eight times the volume of the original resin. The floc volume depends on the cation/anion ratio.

The ion exchange kinetics of powdered resin is up to 100 times faster than bead resins, and the floc which they form also acts as an electrostatic filter.

Due to its porosity, it can retain even the most highly divided colloids, insoluble corrosion products (crud) and charged particles (including ions). Removal of these particles is essential, as they cause local deposit in steam-raising circuits, which acts as a starting point for corrosion and damage.

Powdered resins have excellent coating properties on pre-coat filter units, and allow water to pass at high-velocity, without incurring any serious pressure loss.

Powdered resins work as a pre-coat, either alone or together with inert fibrous material.

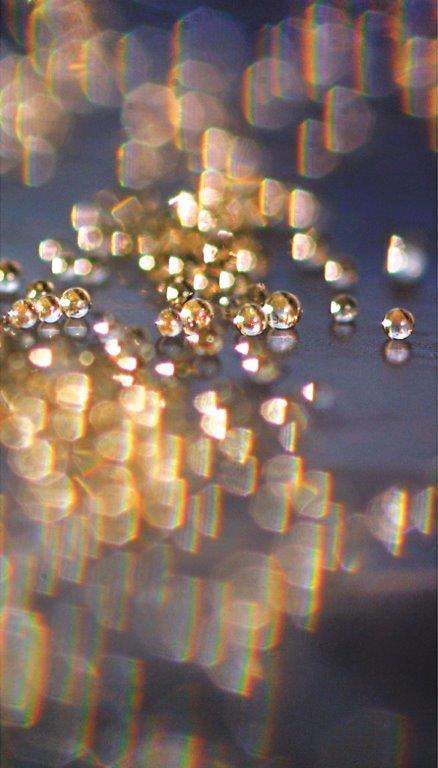

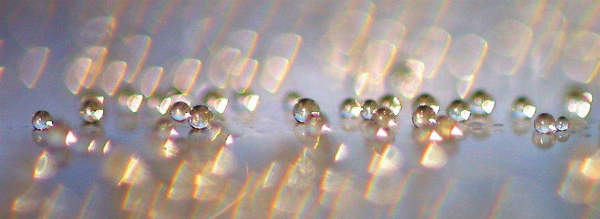

Bead resins

Bead resins are available as a weak or strong base anion, as well as weak or strong acid cation. They are typically used as a final stage for desalination of feed water in different types of cation and anion filter combinations, or mixed bed filters.

Macroporous anion resins can also be used as a scavenger resin, collecting decomposed organic matter from the water.

Mixed bed resins can be delivered in a cation/anion ratio as required by our clients. Other properties of the resins can also be adjusted to suit the intended client application.

Indicator resins

Finex indicator is typically a gel-type, strong acid cation exchanger. During the manufacturing process, the resin is injected with a special indicator dye which reacts to the acid within the beads. Therefore, the resin in hydrogen-form will exhibit a purple colour, indicating a local acidic environment. When the resin is exhausted, the local bead acidity decreases and the indicator signals the resulting ‘pH rise’ with a colour change from purple to yellow.

The indicator dye used is very resistant against wash-out. The resin is delivered freshly regenerated and washed for optimal performance. It is designed for water quality control applications in power plants and comparable facilities.

Anion and mixed bed indicator resins are also available.

Please use the form below to send us your business enquiry.