Voith Turbo BHS Getriebe GmbH (BHS) manufacture high performance turbo gearboxes, couplings and rotor turning gear units for high-speed and industrial applications for the power plant equipment industry. We have realised turbo gear unit products for applications up to a transmitted output of 80MW or rotational speeds of up to 80,000rpm. BHS’ client base includes numerous global players and leading original equipment manufacturers and operators, all of whom value our products and services.

Today the company positions itself as a high-tech gear unit manufacturer offering a modern machine park and a highly-qualified workforce. Extensive measures are in place to guarantee the quality of our products.

PARALLEL SHAFT GEAR UNITS

BHS turbo parallel shaft gears ensure the provision of reliable high-power transmissions and are driven by electric motors, gas / steam turbines or internal combustion engines.

Our parallel shaft gears are specially suited to high-speed applications and are designed for continuous operation. Depending on application, the wheel sets are designed as helical or double helical gears with or without thrust cone. Our range includes:

- A-series, transmission of large outputs at low ratios

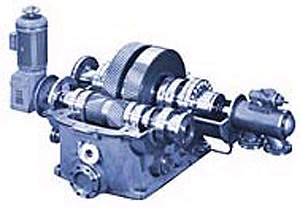

- A-series parallel shift gear unit (type AD63Q) with mounted pump and BHS rotor turning gear unit

- H-series, transmission of average outputs and average ratios

- A-series, special load gear unit for gas turbines

- Auxiliary gear unit with claw coupling

BHS turbo parallel shaft gears are used wherever a reliable system is demanded. These gears achieve high speeds and power densities. They are built both in horizontal and vertical arrangements, which makes them highly adaptable. Additional units, such as lubrication oil pumps and rotor turning gears, can be mounted on the free shaft ends of the gears.

OEMs and plant operators prefer BHS as a supplier of turbo parallel shaft gears because of our ability to reliably transmit high power and speeds with low power losses.

Turbo parallel shaft gears are designed and manufactured at BHS for power ranging from 100kW to 100,000kW and speeds of up to approximately 40,000rpm.

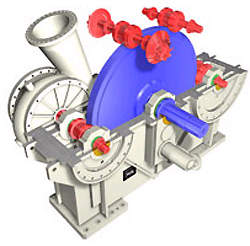

INTEGRAL GEAR UNITS

Our integrally geared compressors compress gases to a higher energy level or produce additional drive output using gear expanders. BHS integral gears form an “integral” unit with the compressors and / or expanders. Our range of integral gear units includes:

- WG series multi-pinion integral gear unit with thrust cone

- Single pinion integral gear unit TG-series with thrust collar

- Integral-type spur-geared planetary gear unit (type RTGF) ready to house a compressor impeller

Integrally geared compressors generate lower costs compared with other types of compressor, offer a constantly expanding area of use / high efficiency levels and save space in the workplace. Multi-shaft integral gears are also equipped for intermediate cooling of the medium and for integrating various power machines such as electric motors, steam, gas and expansion turbines.

BHS integral gears transmit very high outputs and speeds with low power losses. Through the optimum interaction of components, such as impeller, bearings, toothing, sealing systems and the casing, we provide our customers with competitive advantages.

Integral gears are designed and manufactured at BHS with up to ten compressor stages, weights of more than 50t (55 US tonnes) and gear wheel diameters of up to approx. 3m (9.9ft).

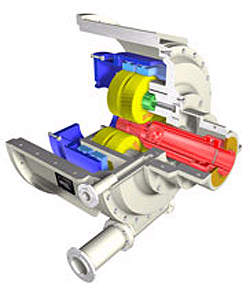

PLANETARY GEAR UNITS

BHS planetary gears are built for a wide range of power and speed requirements and are used for a diverse range of applications. Our planetary gears are used predominantly in turbo systems with steam / gas turbines, compressors, blowers and pumps. In addition, planetary gears are also suitable for high-speed test stands or even hydroelectric power stations.

BHS builds planetary gears up to outputs of 40MW, achieves speeds of up to 80,000rpm and torques of up to 500kNm. BHS offers three types of gearbox: free-standing, flange-mounted on the high-speed side (SPEED-PACK) or on the slow-speed side (E-PACK®).