AWB, located in Lampertheim, Germany, has offered precision manufacturing of demanding components to its clients since 1995.

AWB specialises in shaping special materials such as Inconel, Hastelloy and other Haynes materials, Stellite, as well as the manufacturing of safety-related components. In addition, AWB provides innovative logistic concepts and consulting services in the area of metal shaping.

Due to a modern quality management system and extensive quality documentation, every individual component of AWB is traceable throughout the complete production and supply chain.

AWB focuses first and foremost on the integrated support of its clients, with experts’ collaboration in development projects, the continuous enhancing of manufacturing processes and the consulting of our clients in the realisation of large-scale projects; AWB is much more than just an ordinary contract manufacturer.

AWB offers the following products and services:

- State-of-the-art precision manufacturing of alloyed materials

- Manufacturing of safety-related components

- Production of individual components and small batches with high flexibility and fast turn-around times

- Extensive quality documentation, quality assurance and traceability for individual components throughout the complete production and supply chain

- Execution of client orders by a single service provider and coordinated procurement of components manufactured by other companies for the purpose of streamlining the processes for our clients

- Offer of every technologically feasible production process due to close collaboration with subsidiaries and partners of AWB

- Production of large / complex steel and stainless-steel weldments by an AWB subsidiary in the Czech Republic

- Worldwide shipping and customs clearance

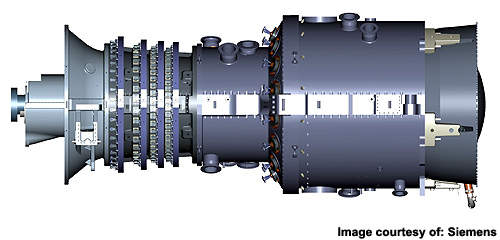

Turbine components

AWB provides a large product range in turbine / power plant technology. Our parts are used in industrial and gas turbines for commercial energy generation in a power range up to 400MW.

Examples of components built by AWB:

- Components for hot-gas areas, including burners, nozzles, burner lances, blades for burners and parts of cooling systems

- Components for cool-gas areas, for example bolts, nuts, flanges, clamps and special screws, etc.

- Components for the turbine periphery, such as anchor bolts, weldments, air intake and air washing systems

- Tools for turbine installation and maintenance

Precision manufacturing

AWB offers precision manufacturing of components with an accuracy of up to +/- 5µm. In order to obtain accuracy at this high level, AWB uses state-of-the-art quality assurance processes throughout the complete production chain.

Throughout the complete process of precision manufacturing, our clients profit from the high technical qualifications of our employees and the strict process control of AWB. The entire process of precision manufacturing is constantly monitored by our integrated computer systems. If required, AWB ensures the tractability of individual products.

Some of the components used are:

- Hot gas components for gas turbines (burners, nozzles, etc.)

- Components shrunk into turbines (cooling tubes, nozzles, flanges)

- Assemblies of medical technology

- Parts and assemblies of submarine cables

Special materials

AWB has over 15 years of experience in the field of procurement and shaping of special materials like HIP Stellite, Inconel, Hastelloy, Titanate and other Haynes materials.

When it comes to the procurement of special materials, one is able to choose from a large selection. AWB procures special materials from distributors or directly from manufacturers located domestically and abroad and stores them temporarily as needed.

Some examples of materials AWB procures:

- Heat-resisting high alloyed steels, such as Inconel, Waspaloy, Hastelloy and other Haynes materials

- Salt-water-proof copper and brass alloys

- Acid-proof stainless steels for food and medical technology

- Other stainless steels of every quality class

- Titanium

- HIP Stellite, which has excellent mechanical properties

Weldments and large components

AWB manufactures weldments and large components with a weight of up to 25t. In this way, AWB applies its knowledge in the area of working with stainless and carbon steel, in order to manufacture high-quality weldments and large components.

Examples for the components AWB manufactures in the field of weldments and large components:

- Air intake systems for gas turbines

- Bearing blocks for turbine rotors

- Lifting devices for entire turbines and turbine parts

- Engine frames

- Scaffolds and constructions of any kind

High-quality management system

It is AWB’s philosophy to offer its customers the highest quality in all products and services. Therefore, AWB has created an extensive quality management system, which manifests itself in different ways:

- An extensive quality documentation that fits our clients’ needs

- High-precision manufacturing, where quality assurance measures are used throughout the whole manufacturing process

- Many certifications, which acknowledge the internal quality management of AWB