Since 1974, STEJASA has been a leading supplier of dampers and complete bypass systems that are able to operate in the worst working conditions in the power technology industry.

Exhaust bypass systems for gas turbines

STEJASA designs and supplies exhaust gas systems for gas turbine installations. Our gas systems are designed according to GT and plant characteristics in simple cycle or combined cycle mode.

Advantages of our bypass systems include:

- Power generation during boiler erection or boiler maintenance

- Control of exhaust flows with diverter blades, reducing boiler thermal stresses at startup

- Emergency shut-down of HRSG

Our exhaust gas systems generally include the following:

- Diffuser

- Bypass dampers or elbow

- Stack with supporting structure

- Silencer

- Expansion joints

- Ladders and platforms

- Aircraft warning lights

- Emission test ports

Additionally, STEJASA designs special configurations with stack, directly supported by the bypass damper, therefore eliminating the need for a supporting stack structure and reducing civil works and the erection period.

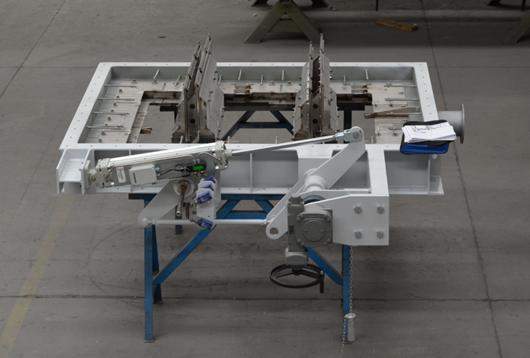

Diverter dampers

We design and manufacture diverter dampers, and benefits of our single blade dampers include:

- Smaller seal perimeter than multiple blade dampers

- No requirement of simultaneous movement of various blades

- Minimum pressure drop compared to multiple blade dampers

- Can be manufactured in modules for easy shipping and field assembly

For 100% sealing efficiency, we fit either a double-seal row or ‘v’-shaped seal. The cavity formed by the seals and the landing bars is pressurised by a small fan in order to provide an effective air barrier and zero cross-blade leakage.

The entire actuator system of a diverter damper is externally mounted and can be inspected and maintained while the main plant is running.

Critical actuator sizing for diverters

The sizing of the actuator is one of the most critical tasks in the design of a diverter. For both the direct shaft and toggle system drive, the following parameters must be considered:

- Blade weight load: the weight of the diverter blade when horizontal, as well as the friction generated by the lever heads

- Pressure duct loads: the actuator must be sized according to the pressure generated by the fluid on the surface of the blade

- Blade seals loads: an additional torque will be provided in order to correctly tighten the seals

Multi-louvre dampers and butterfly dampers for the power technology sector

We design and supply a range of butterflies and multi-louvres for all applications in the power technology industry. STEJASA can design butterflies and multi-louvres for external insulation or supply them with internal insulation.

STEJASA’s butterfly and multi-louvre dampers are designed with metal-metal or elastic seal systems, depending on the required tightness. The damper construction is reinforced to withstand all the static and dynamic stresses inherent to the damper.

Our blade design allows a very low-pressure drop and an efficient flow control, and all accessories and drives are mounted on the casing

Our butterfly dampers are single bladed and are used to control and / or isolate gas flow. STEJASA’s multi-louvre dampers are equivalent to butterfly dampers but have two or more blades.

For 100% tightness efficiency, tandem dampers with air sealing are also available.

STB blanking plates and guillotine dampers

Generally used in gas turbine installations, our STB blanking plates allow safe access to HRSG. In normal operation, the blanking plate is hanging from a supporting structure. The plate is inserted by unbolting the flange at the expansion joint, which is then compressed to allow the plate to be inserted.

STEJASA’s STR repair guillotines include a frame and a blade with its support. The frame is provided with a removable cover that remains closed when the plate is in or out of the gas stream. In cases where high tightness is required, the blade is supplied with seals all around its perimeter. For large-sized guillotines, a self-locking system is standard. Blade actuation can be done using a manual or electric drive.

Our STS guillotines are used in process industries and are fully automated, therefore controlled by the plant SCADA. The gullotine bonnet ensures that there is no leakage from the damper to the atmosphere under any conditions, and the blade is reinforced to minimise deflexion and stresses.