With nearly 30 years of accumulated expertise in heat transfer, Britannia Heatex is a natural choice for the design and manufacture of high quality heat exchangers, with an emphasis on developing bespoke solutions to overcome specific problems.

Plate-fin heat exchangers

Our extended-surface heat exchangers use patentecd ‘Elfin’ plate technology, resulting in class-leading levels of performance and durability.

The ability to specify virtually any combination of tube and fin material, including copper alloys, stainless steel and titanium, gives engineers the freedom to balance budget and longevity considerations.

Our expertise in the use of vortex clean air technology reduces pressure loss and fin fouling, resulting in lower maintenance costs and reduced energy consumption.

Shell and tube heat exchangers

Our experience of a broad spectrum of industries and applications means that we are able to offer a very competitive design and manufacture service for complete shell and tube heat exchangers.

In-house design engineers make use of the most advanced thermal and mechanical design techniques including thermal modelling and computational fluid dynamics (CFD).

Our welding department carry approvals in accordance with a range of internationally recognised standards such as: ASMR VIII/1; ASTM TEMA B, C; and R; BS PD 5500.

Tube bundles and U-tube bundles

Britannia Heatex manufactures tube bundles for both new and existing applications, including direct replacements for existing units. However, our extensive knowledge and experience allows us to offer longer life expectancy, often at similar or lower cost than the original manufacturer’s unit.

Our extensive stockholding of heat exchanger tubes, coupled with a dedicated in-house tube manipulation department means that both straight and u-tube bundles can be manufactured on short delivery times.

Bespoke heat exchangers

Britannian Heatex has been at the forefront of an ongoing drive to reduce maintenance and downtime at several power stations in the United Kingdom. This was facilitated by re-manufacturing coolers using titanium tubes and tube-plates, resulting in significantly increased resistance to erosion and corrosion and thus a potential ten-fold increase in expected service life.

In air-cooled application, ‘Elfin’ extended surface technology allows the cost effective application of copper fins onto titanium tubes, a process which is inherently difficult using other conventional finning techniques.

Plain tube bundles are also catered for, as are sectional radiator cores and hydrogen coolers.

Heat exchanger services

At Britannia Heatex, we pride ourselves on offering innovative, unique and inspiring solutions for all kinds of problems. One common issue is that of accessibility. If the old heat exchanger cannot be removed then it is likely we have encountered the problem before and have a workaround.

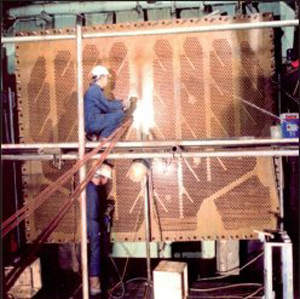

When it is impractical, due to size or time constraints, to remove an existing heat exchanger from a site or vessel, Brittania Heatex provides professional, worldwide on-site service.

Our highly skilled, fully equipped fitters are available to travel anywhere in the world, usually at short notice, to undertake such things as commissioning, re-tubing, installation of tube inserts and tube seals, and also the fitting on our patented tube-plate protection and repair system.