Van Geffen Vibration Monitoring Services (Van Geffen VMS) is an independent consulting and service company specialised in preventing and solving problems with rotating machinery. Since 1987 we have supported our customers with practical advice and resolved malfunctions with the sophisticated use of state-of-the-art equipment.

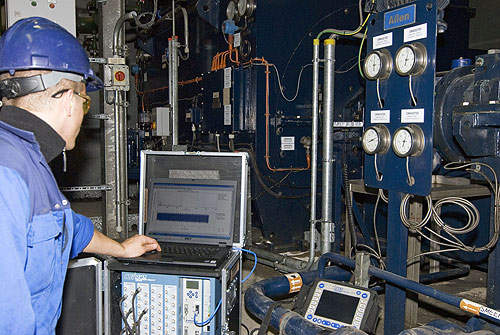

Vibration measurements, inspections and analysis

Vibration measurements are widely accepted as the most effective technology for diagnosing or trouble shooting problems with rotating machinery. However, correct measurements, analyses and interpretations require extensive knowledge and experience.

Condition monitoring for rotating machinery

Critical machinery is often protected with permanently installed vibration protection systems. In case of a mayor malfunction theses systems will trip the machine; however, just the scanning and trending of the vibration levels isn’t sufficient for reliable condition monitoring.

Van Geffen VMS provides reliable and cost-efficient condition monitoring programmes for all your rotating machinery whether or not equipped with a protection system.

Roller bearing fault detection

In contrast to most heavy-duty turbines, aeroderivative turbines are usually equipped with rolling element bearings. The failure of these bearings quickly leads to large clearances followed by catastrophic failure. Besides the monitoring and analysis of sleeve bearings and rotor dynamics, Van Geffen VMS also has a vast experience with the monitoring and early detection of bearing faults in aeroderivative turbines.

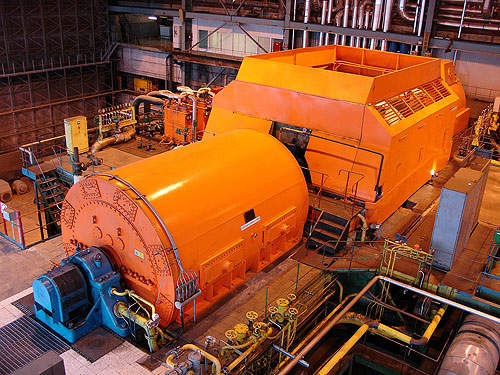

Trouble-shooting rotating machinery problems

High vibrations, sudden machinery trips or excessive bearing wear can be a nightmare for every machinery manager. Overhauls or repairs are only useful when the cause of the malfunction is exactly known. Without a thorough analysis, the problem is likely to occur again. By trouble-shooting the problem, we quickly identify the root-cause. Our quick analyses of acute problems guarantee the shortest possible downtime and significantly reduce the chances of reoccurrence.

Field balancing of rotating machinery

Imbalance in rotating machinery causes high vibrations and leads to unnecessary wear. Balancing your rotating equipment will prevent vibrations and increase the machinery lifetime.

Ever since its founding, field balancing has been one of the spearheads of our company. Our strength is within our 20+ years of experience and the high number and diversity of balance jobs that we perform on a daily basis – both on-site and in our workshop.

Laser alignment of rotating machinery

Misalignment is directly or indirectly responsible for more than 50% of all problems with rotating equipment. A correct alignment is therefore of the upmost importance, even when a flexible coupling is used.

Van Geffen VMS and its skilled engineers use the most modern laser optic measurement equipment and have the knowledge and experience to measure and correct numerous alignment related parameters as:

- Shaft alignment

- Cardan coupling

- Pulley

- Softfoot measurements

- Thermal growth

- Line bore

- Geometric parameters such as flatness, levelness, perpendiculars and parallelism

Global services for rotating machinery

You will never call on us in vain. Problems always occur at an inconvenient time. This demands flexibility from the specialists helping you to solve your problems. Van Geffen VMS guarantees you this flexibility: 24 hours a day, seven days a week, 365 days a year. We always have time to prevent downtime.

We measure, analyse and we consult – worldwide, at any given time and in all industry segments.

Certifications

We are SCC (VCA) certified and work according ISO standards. Our specialists are NOGEPA, OLF and OPITO certified and posses all necessary papers to directly travel to, and to safely work on board ships, construction barges, and oil and gas rigs.