Acosense provides real-time, online active acoustic spectroscopy technology to optimise process fluid analysis in the wastewater treatment and chemical industry.

Acosense provides real-time, online active acoustic spectroscopy technology to optimise process fluid analysis in the wastewater treatment and chemical industry.

Fluid measurement tools to optimise power plant processes

Acosense’s liquid measurement solutions produce accurate results of up to three properties, including opaque, corrosive, abrasive, viscous and / or coating liquids.

The instruments enable customers to identify and optimise methods in a simple, reliable and safe way, leading to significantly reduced costs, energy use and environmental impact.

The process industry faces increased pressure to improve efficiency and reduce its carbon footprint.

Previously available analysis solutions do not have the accuracy or fast response time to provide the sector with the programme data needed to decrease energy consumption or increase production capacity and quality.

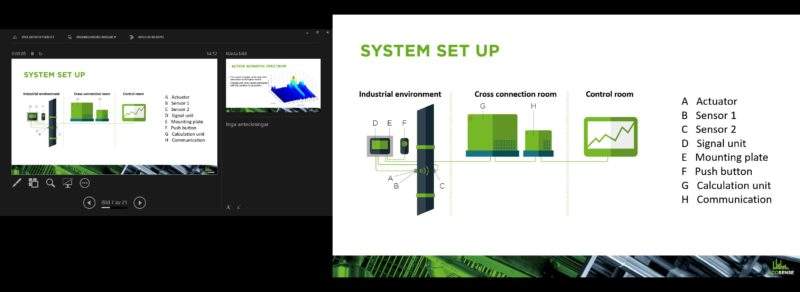

Acosense’s unique Acospector technology digitises plant systems, delivering continuous analytical values without interruptions and invasive installation procedures.

Acosense has initially focused on the pulp and paper / chemical industry, but the products can be used in any system involving containment fluids that need to be monitored quickly and precisely such as the food and beverage sector.

Accurate online process fluid analysis instruments

Acospector enhances the industrial process by using patented technology to provide precise real-time liquid property monitoring.

In rare cases of maintenance, no health risks occur as the sensors are on the outside of the pipe / vat.

Cost-effective analytical systems for the manufacturing sector

Customers regularly receive information about the analytical process with the Acospector, which ensures savings on energy and costs. The reliable tool enables clients to reduce variations and run the plant efficiently, leading to high-quality products, as well as a reduction in raw material usage and waste.

The instrument continuously conducts detailed analyses to ensure it is safe for personnel and processes.

Acosense devices prevent the contamination of customer liquids and contribute to the efficient use of raw materials. They also involve as little effort as possible for the customer in both installation and start-up, while the need for maintenance is minimised.

Multiple fluid property measurement instruments

There are several different instruments for monitoring process fluids, but most of these have limitations, including poor accuracy, risk of personal safety, continuous maintenance, complex procedures and administration, or simply not being able to analyse a particular property or process section online. Instead, the tools often require the user to take manual samples to be studied in the laboratory.

Acospector has been used to analyse multiple properties such as fibre length, sludge and dry matter content, viscosity, and particle size. It also handles up to three properties at one measuring point, reducing the need for multiple instruments during the process.